Size mixer

A technology of mixer and slurry, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problem of incomplete double liquid plugging, achieve double-pipe diversion transportation, adjust solidification time, and have significant economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical content of the present invention, a specific embodiment is provided below, and the present invention is further described in conjunction with the accompanying drawings.

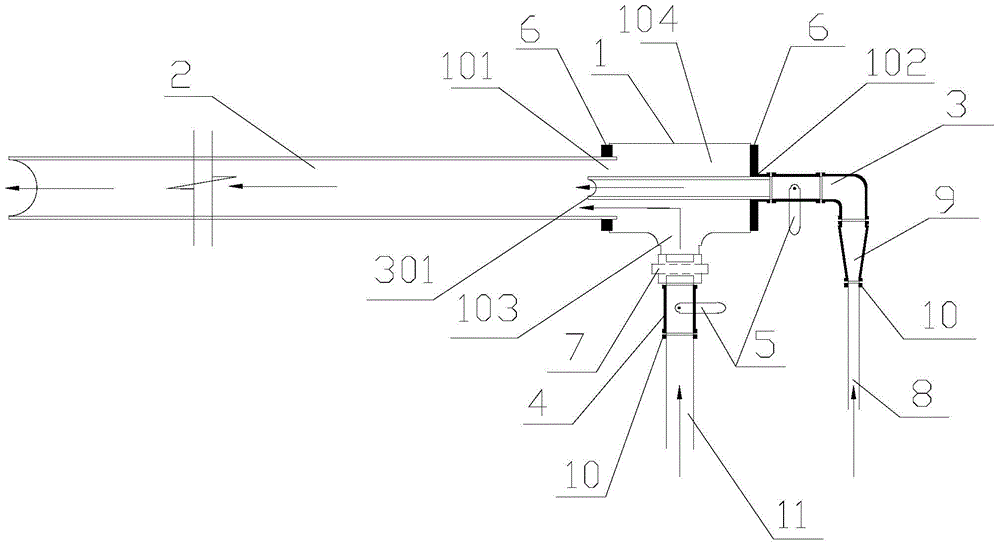

[0027] see figure 1 The slurry mixer of the present invention includes a three-way pipe fitting 1, a grouting nozzle 2 connected to the outlet 101 of the three-way pipe fitting 1, and a first slurry inlet pipe 3 connected to the first inlet 102 of the three-way pipe fitting 1 . A second slurry input pipe 4 connected to the second inlet 103 of the three-way pipe fitting 1 , wherein one end of the first slurry input pipe 3 passing through the inner cavity 104 of the three-way pipe fitting 1 is a slurry confluence point 301 , and the slurry confluence point 301 is located at or near the outlet 101 of the three-way pipe fitting 1 . The present invention not only realizes the double-pipe diversion delivery of the double-slurry, but also realizes the uniform combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com