Synergistically enhanced copper matrix composite material and preparing method thereof

A technology of copper-based composite materials and copper salts, which is applied in the field of copper-based composite materials and its preparation, and can solve the problems of low copper hardness, limited wide application, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

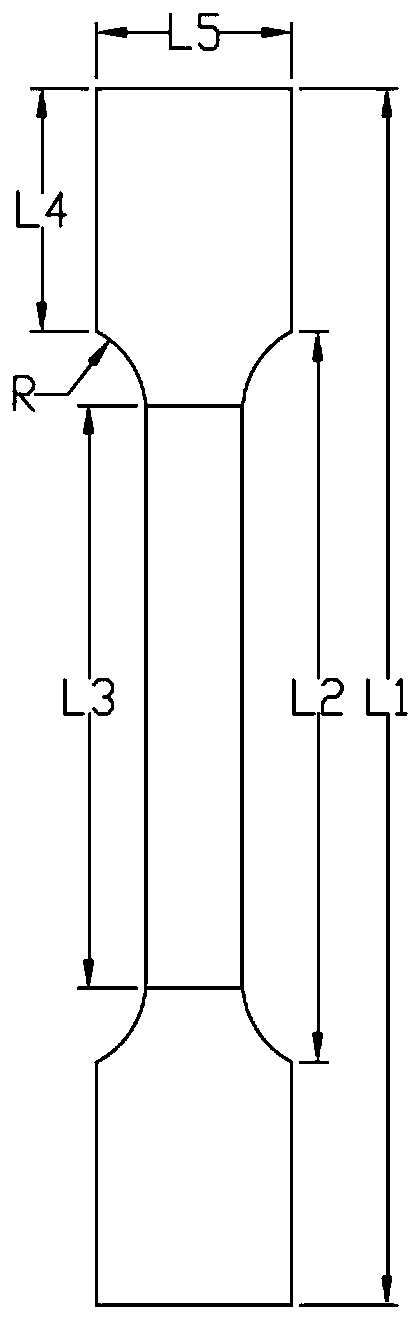

Image

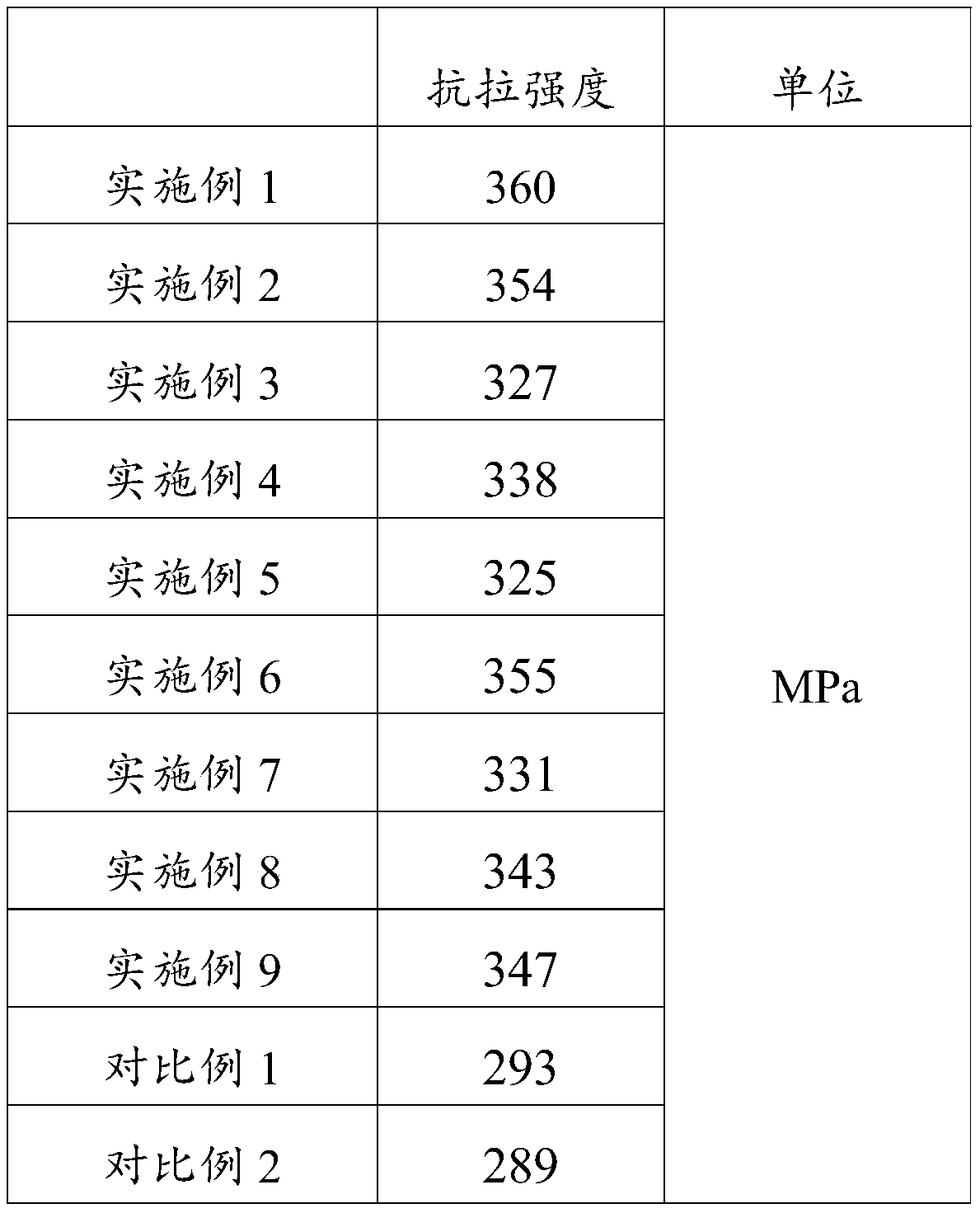

Examples

Embodiment 1

[0038] S101: Hexadecyltrimethylammonium bromide, carbon quantum dots, carbon nanotubes and Ti 3 C 2 Mxene was sequentially added into deionized water at a mass ratio of 1:1:1:1, and ultrasonically dispersed at room temperature for 10 minutes to obtain a dispersion; wherein, hexadecyltrimethylammonium bromide, carbon quantum dots, carbon nanotubes and Ti 3 C 2 The mass sum of Mxene is 1.2% of the dispersion;

[0039] S103: Add 1 volume part of the dispersion liquid dropwise to 200 volume parts of copper acetate aqueous solution with a copper ion concentration of 6.4 g / L, stir at a speed of 100 r / min for 5 minutes, then add 20 volume parts with a mass fraction of 5% The NaOH solution, obtains the suspension that comprises copper hydroxide;

[0040] S105: heating the suspension to 50° C., continuing to stir, and adding 1 volume part of hydrazine hydrate solution with a mass fraction of 1% to reduce the copper hydroxide therein to cuprous oxide;

[0041] S107: Filter, wash,...

Embodiment 2

[0046] S101: Hexadecyltrimethylammonium bromide, carbon quantum dots, carbon nanotubes and Ti 3 C 2 Mxene was sequentially added to deionized water at a mass ratio of 1:1:1:2, and ultrasonically dispersed for 20 minutes at room temperature to obtain a dispersion; wherein, hexadecyltrimethylammonium bromide, carbon quantum dots, carbon nanotubes and Ti 3 C 2 The mass sum of Mxene is 0.5% of the dispersion;

[0047] S103: Add 1 volume part of the dispersion liquid dropwise to 200 volume parts of copper acetate aqueous solution with a copper ion concentration of 12.8g / L, stir at a speed of 200r / min for 10min, then add 20 volume parts with a mass fraction of 6% The NaOH solution, obtains the suspension that comprises copper hydroxide;

[0048] S105: heating the suspension to 75° C., continuing to stir, and adding 15 parts by volume of a glucose solution with a mass fraction of 15% to reduce the copper hydroxide therein to cuprous oxide;

[0049] S107: Filter, wash, and dry ...

Embodiment 3

[0053] S101: Hexadecyltrimethylammonium bromide, carbon quantum dots, carbon nanotubes and Ti 3 C 2 Mxene was sequentially added to deionized water at a mass ratio of 1:1:1:3, and ultrasonically dispersed for 30 minutes at room temperature to obtain a dispersion; wherein, hexadecyltrimethylammonium bromide, carbon quantum dots, carbon nanotubes and Ti 3 C 2 The mass sum of Mxene is 0.6% of the dispersion;

[0054] S103: Add 1 volume part of the dispersion liquid dropwise to 200 volume parts of copper acetate aqueous solution with a copper ion concentration of 19.2 g / L, stir at a speed of 300 r / min for 10 min, then add 20 volume parts with a mass fraction of 7% The NaOH solution, obtains the suspension that comprises copper hydroxide;

[0055] S105: heating the suspension to 100°C, continuing to stir, and adding 15 parts by volume of a 20% glucose solution by volume to reduce the copper hydroxide to cuprous oxide;

[0056] S107: Filter, wash, and dry the product obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com