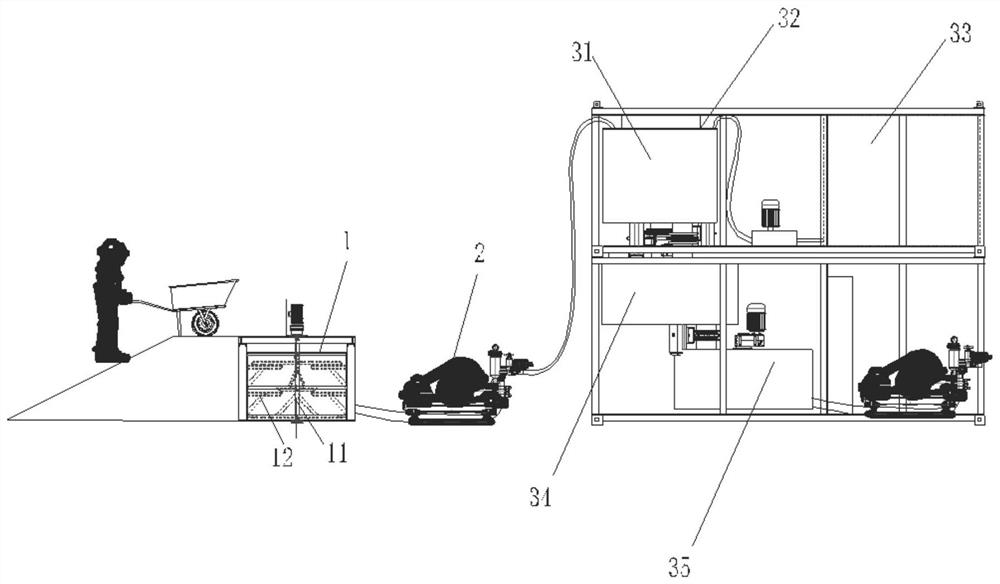

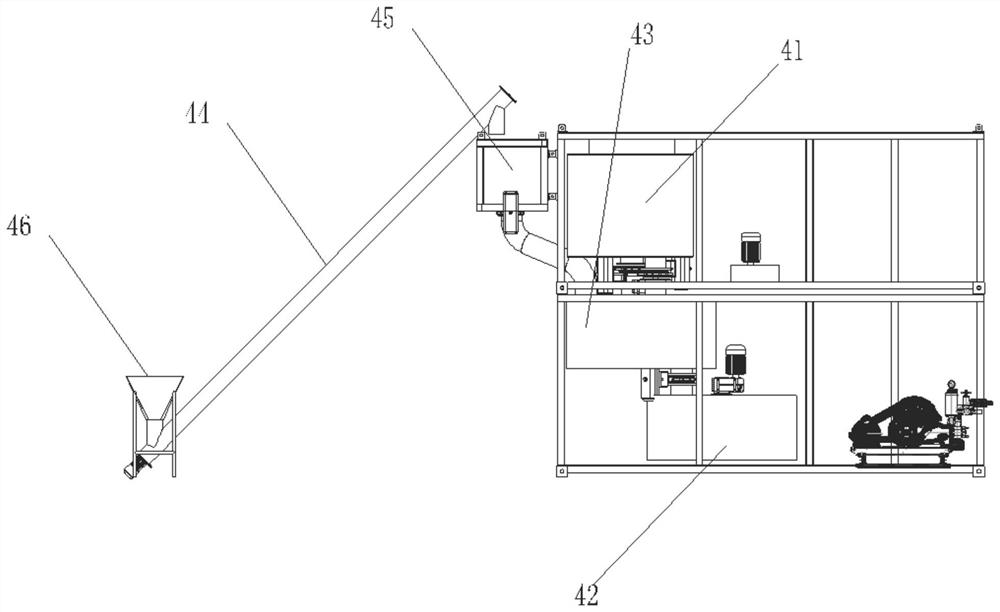

Solidified soil preparation system

A technology for preparing system and solidifying soil, applied in the field of civil engineering, can solve the problems of construction quality impact, insufficient strength of solidified soil, inability to meet engineering needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0024] In this embodiment, in this embodiment, a moist caking material is added to the solidified soil, and the main component of the material is natural dihydrate gypsum with a chemical formula of CaSO4·2H2O. Natural dihydrate gypsum is also called air-hardening inorganic gelling material. This kind of gypsum is lumpy and lumpy, and has cohesiveness. It is directly mixed into the undisturbed soil, and it is not easy to stir and cannot be mixed evenly. And the screw conveyor cannot be used for material transportation. If it is used forcibly, it will stick to the blades and pipelines of the screw conveyor, causing failure.

[0025] Adding gypsum into the solidified soil can shorten the solidification time of the solidified soil, adjust the acidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com