High-selectivity synthesis method of 3-phenoxy-1-propanol

A technology of propylene glycol phenyl ether and a synthesis method, which is applied in the directions of ether preparation, alkylene oxide preparation of ether, organic chemistry, etc., can solve the problems of increasing the production cost of propylene glycol phenyl ether, low phenol content, complex production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

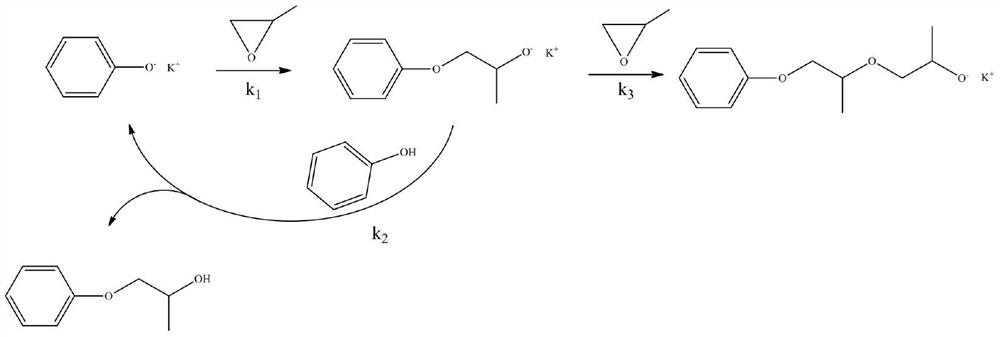

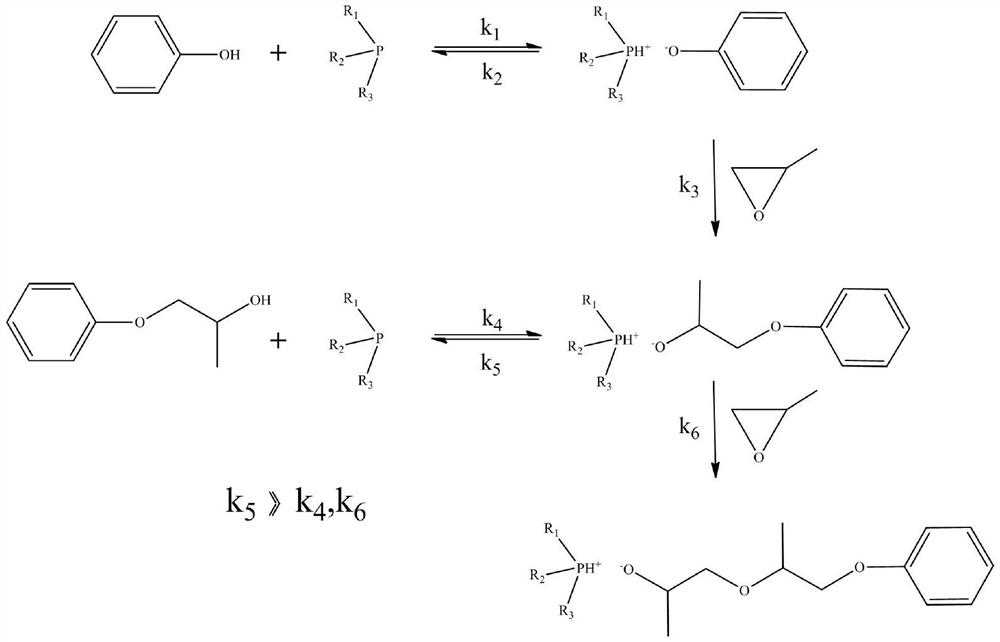

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides a highly selective synthesis method of propylene glycol phenyl ether. The specific steps are: add 1888g of phenol and 15.55g of triisopropylphosphine into a 5L pressure-resistant reactor and mix evenly; connect. Replace air with nitrogen 3 times, until the temperature of the reactor is maintained at about 100°C, start to feed 1187g ethylene oxide, pass through in about 10 hours, continue to react for 3 hours. After the reaction was completed, degas and cool to obtain about 3076g of crude propylene glycol phenyl ether. The phenol content in the product detected by GC is about 96ppm, and the propylene glycol phenyl ether is about 98.2%.

Embodiment 2

[0033] This embodiment provides a highly selective synthesis method of propylene glycol phenyl ether. The specific steps are: add 1888g phenol and 9.33g triethyl phosphite in a 5L pressure-resistant reactor and mix evenly, and mix the propylene oxide metering tank with the pressure kettle connection. The air was replaced with nitrogen for 3 times. When the temperature of the reactor was maintained at about 120° C., 1222 g of ethylene oxide was introduced for about 4 hours, and the reaction was continued for 3 hours. After the reaction was completed, degas and cool to obtain about 3078g of crude propylene glycol phenyl ether. The phenol content in the product detected by GC is about 65ppm, and the propylene glycol phenyl ether is about 98.3%.

Embodiment 3

[0035] This example provides a highly selective synthesis method of propylene glycol phenyl ether. The specific steps are: add 1888g of phenol and 3.16g of triphenylphosphine into a 5L pressure-resistant glass reactor and mix evenly, and mix the propylene oxide metering tank with the pressure kettle connect. Replace air with nitrogen 3 times, until the temperature of the reactor is maintained at about 140°C, start to feed 1268g propylene oxide, pass through in about 2 hours, continue to react for 3 hours. After completion of the reaction, degas and cool to obtain about 3084g of crude propylene glycol phenyl ether. The phenol content in the product detected by GC is about 32ppm, and the propylene glycol phenyl ether is about 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com