Small film decal paper not prone to cracking as well as preparation method and use method of small film decal paper

A decal and explosive technology, which is applied in the field of small-film decal that is not easy to detonate and its preparation, can solve the problems of imperviousness, rupture, and bursting of the decal surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

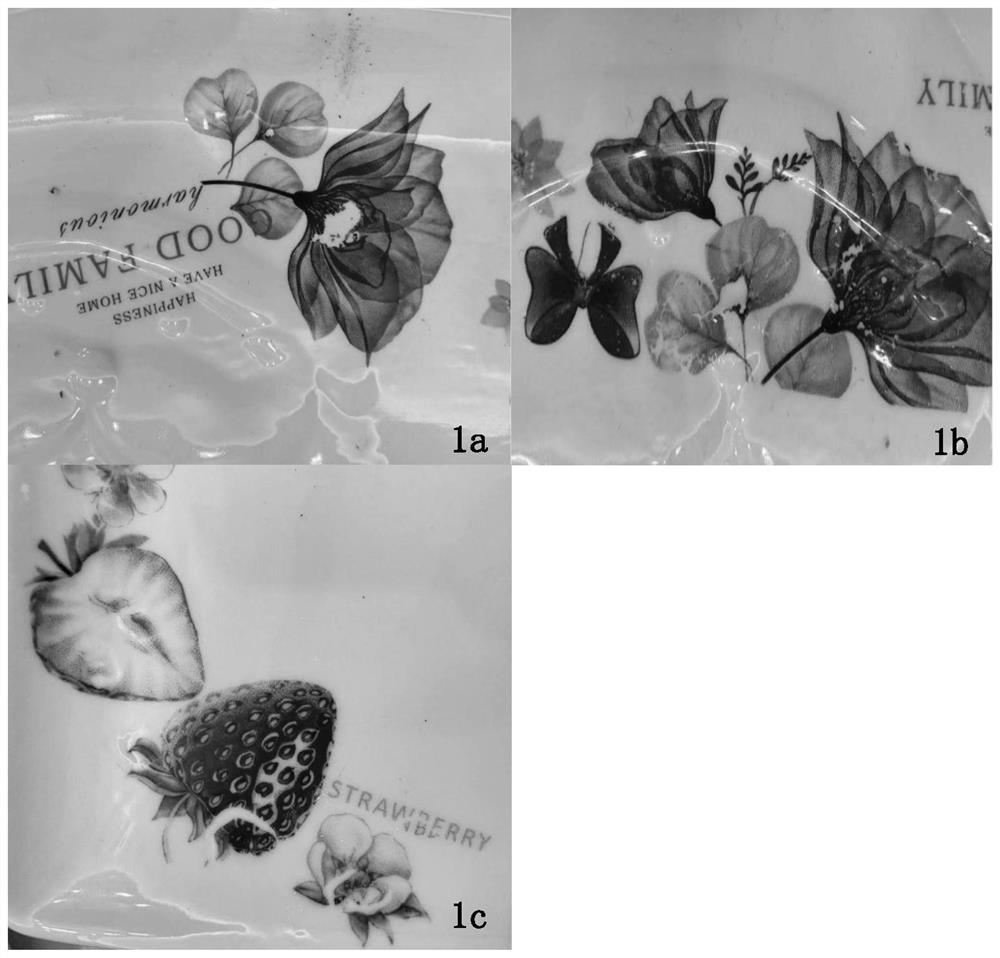

Image

Examples

Embodiment 1

[0085] A kind of preparation method of the small-membrane flower paper that is not easy to burst comprises the following steps:

[0086] Step 1. Prepare water-based varnish and alcohol-soluble cover oil

[0087] 1a) 30% glycol aldehyde acetate, 4.5% ethylene glycol monobutyraldehyde, 3.5% mesitylene, 41% water-soluble polyacrylate, 6% dimethylethanolamine, and 10% dimethyl silicone oil were mixed by mass percentage. % and 5% of water are stirred and mixed evenly to make water-based varnish for subsequent use;

[0088] 1b) 2.8% ethylbenzene, 11.2% xylene, 11.8% n-propylbenzene, 6.7% m-ethyltoluene, 12% trimethylbenzene, 7.3% isopropanol, 2.2% propyltoluene and After the alcohol-soluble polyacrylate 46% is stirred and mixed evenly, the alcohol-soluble cover oil is prepared for use;

[0089] Step 2: Print a layer of ultra-thin alcohol-soluble cover oil on the base paper within the pattern range by using a screen of 350 mesh or more, and form an ultra-thin layer of alcohol-solub...

Embodiment 2

[0100] A kind of preparation method of the small-membrane flower paper that is not easy to burst comprises the following steps:

[0101] Step 1. Prepare water-based varnish and alcohol-soluble cover oil

[0102] 1a) By mass percentage, 27% of glycol aldehyde acetate, 4.1% of ethylene glycol monobutyraldehyde, 3.2% of mesitylene, 45% of water-soluble polyacrylate, 5.5% of dimethylethanolamine, and 10.7% of dimethyl silicone oil % and water 4.5% are stirred and mixed evenly to make water-based varnish for later use;

[0103] 1b) By mass percentage, 2.5% ethylbenzene, 10.3% xylene, 12.8% n-propylbenzene, 6.7% m-ethyltoluene, 11% trimethylbenzene, 6.7% isopropanol, 2% propyltoluene and alcohol-soluble polybenzene Acrylate 48% is stirred and mixed evenly, and then made into an alcohol-soluble cover oil for later use;

[0104] Step 2: Use a 380-mesh screen to print a layer of ultra-thin alcohol-soluble cover oil on the base paper within the pattern range, and form an ultra-thin la...

Embodiment 3

[0115] A kind of preparation method of the small-membrane flower paper that is not easy to burst comprises the following steps:

[0116] Step 1. Prepare water-based varnish and alcohol-soluble cover oil

[0117] 1a) By mass percentage, 33% of glycol aldehyde acetate, 4.9% of ethylene glycol monobutyraldehyde, 3.8% of mesitylene, 37% of water-soluble polyacrylate, 6.5% of dimethylethanolamine, and 9.3% of dimethyl silicone oil % and 5.5% of water are stirred and mixed evenly to make water-based varnish for later use;

[0118] 1b) 3.1% ethylbenzene, 12.1% xylene, 11.3% n-propylbenzene, 7.2% m-ethyltoluene, 13% trimethylbenzene, 7.9% isopropanol, 2.4% propyltoluene and alcohol-soluble polybenzene Acrylate 43% is stirred and mixed evenly, and then made into an alcohol-soluble cover oil for later use;

[0119] Step 2: Use a 380-mesh screen to print a layer of ultra-thin alcohol-soluble cover oil on the base paper within the pattern range, and form an ultra-thin layer of alcohol-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com