Numerical-control metal cutting robot capable of recovering cutting fluid and application of robot

A metal cutting and cutting fluid technology, applied in the direction of metal processing machinery parts, metal processing equipment, large fixed members, etc., can solve the problems that the rising distance on both sides cannot be guaranteed to be synchronized, the processed parts become waste parts, and the cost is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A numerically controlled metal cutting robot capable of recovering cutting fluid, comprising a first housing 1, and a lifting device 2 is provided inside the first housing 1, and the lifting device 2 includes a long rod 201, a first handle 202, a first bevel gear 203, a first Two bevel gears 204 and threaded rods 205, the left and right sides of the outer wall of the long rod 201 are respectively connected to each other by bearings on the left and right sides of the inner wall of the first shell 1, the long rod 201 can rotate through the bearings, and the left end of the long rod 201 is fixed. There is a first handle 202, the first handle 202 can conveniently rotate the long rod 201, the left and right sides of the outer wall of the long rod 201 are fixedly connected with the first bevel gear 203, and the bottoms of the two first bevel gears 203 are connected with the two second bevel gears. The right side of the bevel gear 204 meshes and connects. When the first bevel g...

Embodiment 2

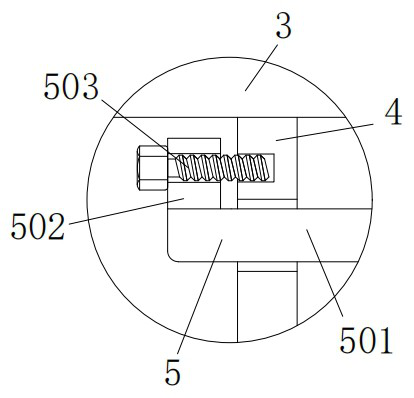

[0038] As an option, see figure 1 with 5 , a CNC metal cutting robot that can recycle cutting fluid, the inside of the second housing 4 is provided with a filter device 5, the filter device 5 includes a screen 501, a block 502 and a first bolt 503, the left and right sides of the outer wall of the screen 501 are connected to the second The grooves on the left and right sides of the housing 4 are fitted with clearances, and the two sides of the screen 501 can move left and right in the grooves of the second housing 4. A block 502 is fixed on the left side of the top of the screen 501. The mesh number of the screen 501 is based on the actual situation. Depending on requirements, the inner wall of the block 502 is threaded to the outer wall of the first bolt 503, and the right side of the outer wall of the first bolt 503 is threaded to the left top groove of the second housing 4, and the first bolt 503 can carry the screen 501 fixed.

[0039] The solution in this embodiment can...

Embodiment 3

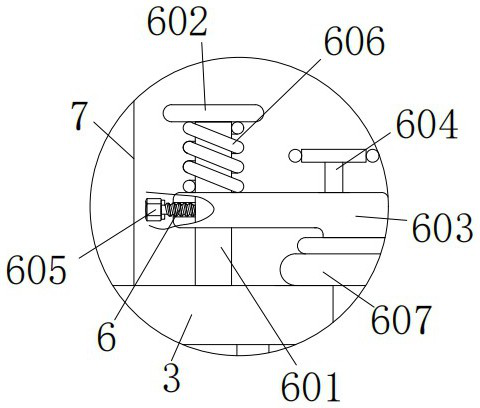

[0041] As an option, seefigure 1 , 3 And 4, the CNC metal cutting robot that can recover the cutting fluid, the tops of the two horizontal plates 3 are provided with a fixing device 6, and the fixing device 6 includes a vertical rod 601, a thin plate 602, a bent plate 603, a second handle 604, and a second bolt 605, spring 606 and workpiece 607, the bottom of the vertical bar 601 is fixedly connected with the top left side of the horizontal plate 3, the top of the vertical bar 601 is fixedly connected with a thin plate 602, the outer wall of the vertical bar 601 slides with the left inner wall of the curved plate 603 Clamping, the curved plate 603 can move on the vertical bar 601, the top right side of the curved plate 603 is fixedly connected with a second handle 604, the second handle 604 can easily pull the curved plate 603, and the left side of the curved plate 603 is provided with a second Bolt 605, the outer wall of the second bolt 605 is threadedly connected with the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com