Deviation correction device for reaming bolt holes and manufacturing method thereof

A technology of reaming bolts and correction devices, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of bolt hole extrusion enlargement, time-consuming, damage, etc., to reduce labor intensity, use quickly, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The production method of the eccentric sleeve during replacement includes the following steps:

[0035] 1. Process the diameter d of the holes of the two parts to 1.5 times the original diameter respectively;

[0036] 2. After the hole processing is completed, it is numbered one by one with the holes on the matching parts;

[0037] 3. Find the maximum deviation e of the coaxiality of each group of holes, and change them into e1,~en respectively;

[0038] 4. The outer diameter of the eccentric sleeve rod is processed to d;

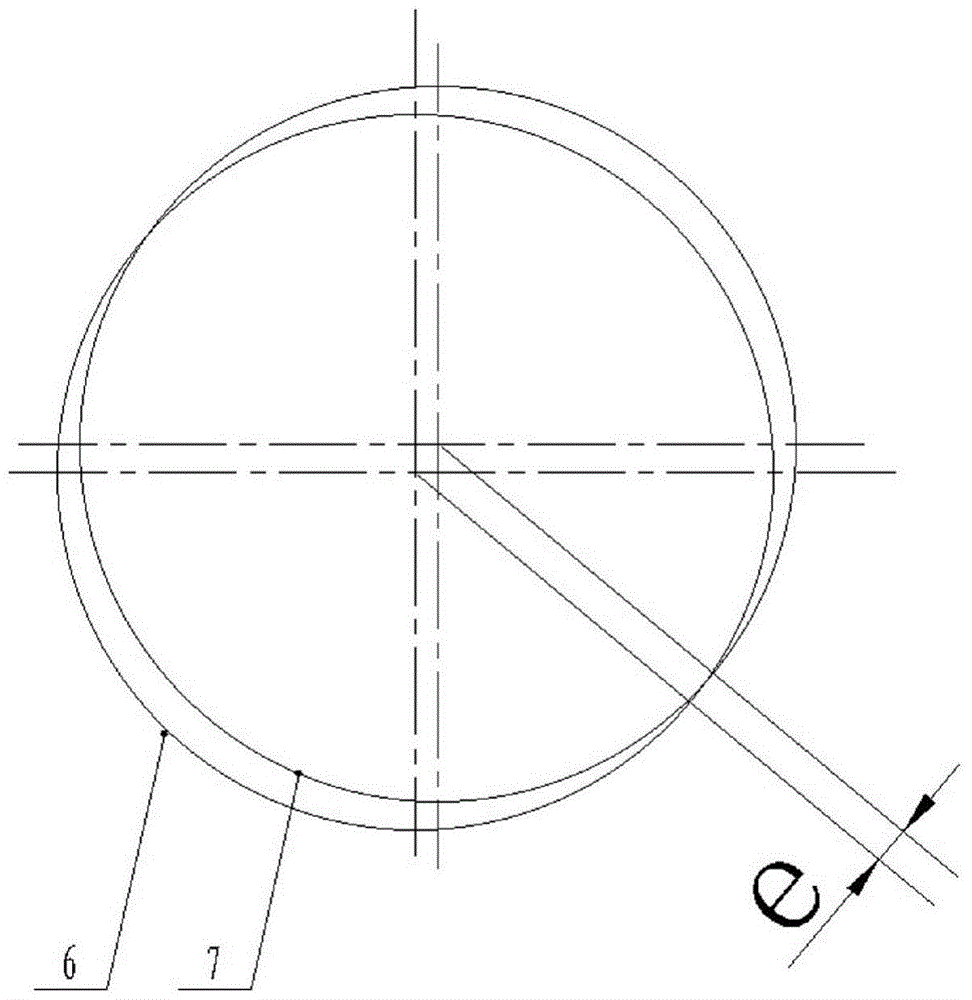

[0039] 5. Process an eccentric sleeve rod for each group of holes, and code the number corresponding to the hole. The distance between the center of the eccentric hole 3 on the eccentric sleeve rod and the center of the outer circle is set to g, the value of g is e, and the diameter of the eccentric hole equal to the diameter of the bolt;

[0040] 6. Cut one eccentric sleeve A3 and one eccentric sleeve B4 on the eccentric sleeve rod after processi...

Embodiment 2

[0045] The production method of the eccentric sleeve during replacement includes the following steps:

[0046] 1. Process the diameter d of the holes of the two parts to twice the original diameter respectively;

[0047] 2. After the hole processing of the two parts is completed, carry out group numbering;

[0048]3. Find the maximum deviation e of the coaxiality of each group of holes;

[0049] 4. The outer diameter of the eccentric sleeve rod is processed to d;

[0050] 5. Process an eccentric sleeve rod for each group of holes, and code the number corresponding to the hole. The distance between the center of the eccentric hole and the center of the outer circle in the eccentric sleeve rod is set to g, the value of g is 0.8e, and the diameter of the eccentric hole is equal to that of the bolt diameter of;

[0051] 6. Cut one eccentric sleeve A3 and one eccentric sleeve B4 from the eccentric sleeve rod after processing, and the length is equal to 0.8 times the thickness of...

Embodiment 3

[0058] The production method of the eccentric sleeve during replacement includes the following steps:

[0059] 1. Process the diameter d of the holes of the two parts to 2.5 times the original diameter respectively;

[0060] 2. After the hole processing of the two parts is completed, carry out group numbering;

[0061] 3. Find the maximum deviation e of the coaxiality of each group of holes;

[0062] 4. The outer diameter of the eccentric sleeve rod is processed to d;

[0063] 5. Process an eccentric sleeve rod for each group of holes, and code the number corresponding to the hole. The distance between the center of the eccentric hole and the center of the outer circle in the eccentric sleeve rod is set to g, the value of g is 0.75e, and the diameter of the eccentric hole is equal to that of the bolt diameter of;

[0064] 6. Cut one eccentric sleeve A3 and one eccentric sleeve B4 from the eccentric sleeve rod after processing, and the length is equal to 0.7 times the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com