Aluminum-based porous composite material as well as preparation method and application thereof

A composite material, aluminum-based porous technology, used in mechanical equipment, springs/shock absorbers, low internal friction springs, etc., can solve problems such as unfavorable impact energy, large stress peaks, relaxation absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

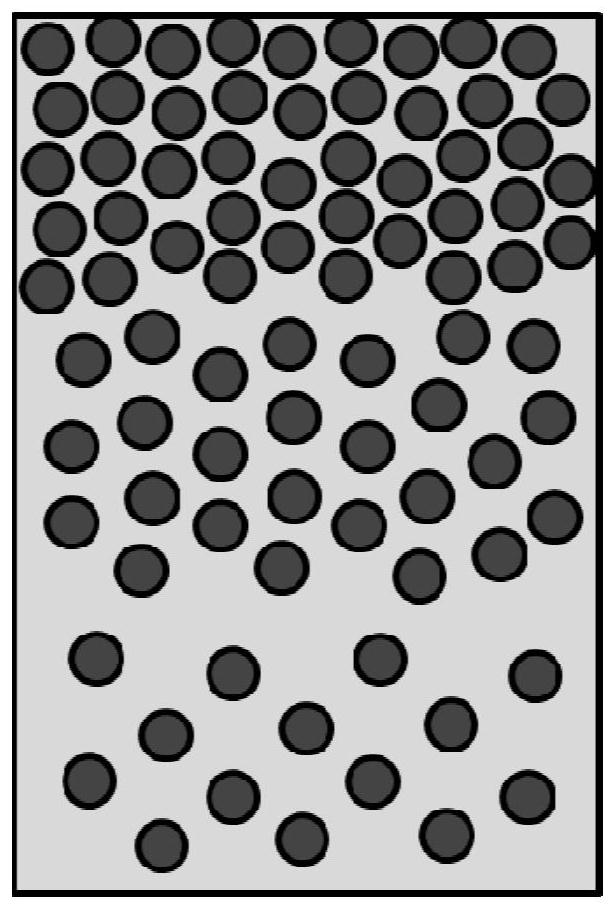

Image

Examples

Embodiment 1

[0053] This embodiment provides a method for preparing an aluminum-based porous composite material, comprising the following steps:

[0054] (1) Preparation of composite blank raw materials: according to the volume fraction of hollow microspheres of 20%, 40% and 60%, respectively weigh 1100 aluminum powder with a mesh particle size of 200 to 400 mesh and Al powder with a mesh particle size of 60 to 150 mesh 2 o 3 Ceramic hollow microspheres (compressive strength is 38MPa), weigh a group of raw materials under the volume fraction of each group, put each group of raw materials into a mixer and mix for 2 hours, then add a mass fraction of 5% water glass binder (that is, the mass fraction of the water glass binder accounts for 5% of the total mass of the hollow microspheres and the aluminum powder) and mix for 4 hours.

[0055] (2) Prefabricated green body forming: the green body raw materials mixed uniformly in step (1) are laid in the steel mold layer by layer along the steel m...

Embodiment 2

[0060] This embodiment provides a method for preparing an aluminum-based porous composite material, comprising the following steps:

[0061] (1) Preparation of composite body raw materials: According to the volume fraction of hollow microspheres of 35%, 55% and 75%, respectively weigh 5A03 aluminum powder with a mesh size of 800-1000 mesh, and a mesh particle size of 150-400 mesh and 500-1000 mesh The purpose glass hollow microspheres (compressive strengths are 42MPa and 110MPa respectively), wherein, in the composite raw material with a volume fraction of hollow microspheres of 35%, the volume fraction ratio of 150-400 mesh and 500-1000 mesh is 2:1; In the composite raw material with a volume fraction of spheres of 55%, the ratio of volume fractions between 150-400 mesh and 500-1000 mesh is 1:1; The volume fraction ratio is 1:2; weigh a group of raw materials for each group of volume fractions, put each group of raw materials into a mixer and mix for 4 hours, then add 5% wate...

Embodiment 3

[0068] This embodiment provides a method for preparing an aluminum-based porous composite material, comprising the following steps:

[0069] (1) Preparation of composite body raw materials: According to the volume fraction of hollow microspheres being 20% and 60%, respectively weigh 4032 aluminum powder with a mesh size of 200 to 400 mesh and iron hollow microspheres with a mesh size of 16 to 30 mesh (anti The compressive strength is 65 MPa), and each group of volume fractions weighs two groups of raw materials, puts each group of raw materials into a mixer and mixes them for 3 hours, then adds a mass fraction of 3% water glass binder and mixes them for 8 hours.

[0070] (2) Prefabricated green body forming: the green body raw material mixed uniformly in step (1), according to the order that the volume fraction of the hollow microspheres of the raw material is 20%-60%-20%-60% along the axial direction of the steel mold from bottom to bottom The top layer is laid in a steel m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com