Precise circuit manufacturing method and circuit board

A manufacturing method and circuit board technology, applied in the direction of mechanical removal of conductive materials, printed circuit components, and secondary treatment of printed circuits, can solve problems such as low production efficiency, complicated procedures, and low pass rate, and achieve improved Production efficiency and qualified rate of finished products, improving signal transmission quality, and avoiding the effect of cost expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A manufacturing method of a precision circuit shown in this embodiment includes the following processing steps in sequence:

[0033] (1) Cutting: Prepare an insulating substrate with a size of 500*600 mm and a thickness of 100 μm, which is a polyimide film.

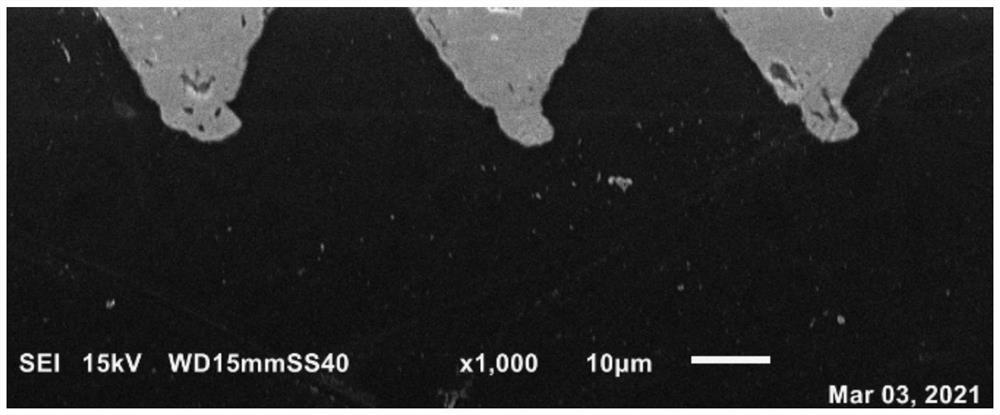

[0034] (2) Laser grooving: use a 355nm UV laser to ablate the corresponding circuit grooves on one surface of the polyimide film according to the circuit pattern required by the design; the marking speed during laser ablation is 100mm / s , the frequency is 50KHz, the pulse width is 5μS, the line width of the line groove is 20μm, the pitch (ie line gap) is 20μm, and the depth is 20μm, and the cross section of the line groove is an inverted triangle.

[0035] (3) Copper sinking: A copper layer with a thickness of 0.3 μm is deposited on the surface of the polyimide film and the inner wall of the circuit groove by chemical deposition of copper. The copper deposition layer is relatively thin. The copper layer on the sur...

Embodiment 2

[0043] The manufacturing method of a kind of precision circuit shown in this embodiment is basically the same as the manufacturing method described in Embodiment 1, the difference is that the following steps are also included after step (5):

[0044] (6) Grinding plate: After nickel sinking, the surface of the plate is smoothed by grinding the plate, so that the surface of the precision circuit is flush with the surface of the insulating substrate.

Embodiment 3

[0046] The manufacturing method of a kind of circuit board shown in the present embodiment, on the basis of the manufacturing method described in embodiment 1 or 2, namely after the nickel sinking of embodiment 1 or the grinding plate of embodiment 2, it also includes the following steps:

[0047] Subsequent process: Then make a solder resist layer on the polyimide film in sequence, immersion gold treatment for solder resist window opening, forming treatment and FQC inspection to obtain a circuit board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com