N-type tin telluride thermoelectric material and preparation method thereof

A technology of thermoelectric materials and tin telluride, applied in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problem of difficult elimination of Sn vacancies, n-type tin telluride synthesis technology and performance reports and research, Tin telluride n-type is difficult to achieve and other problems, to achieve the effect of optimal thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

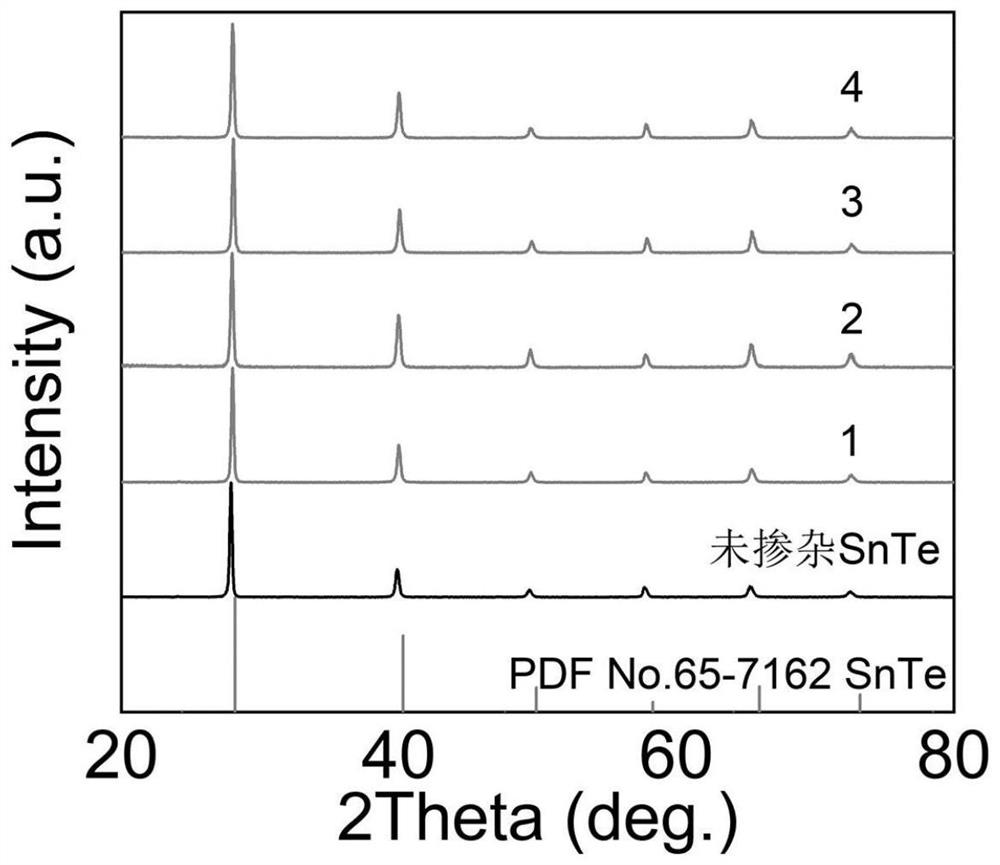

[0044] Such as Figure 18 As shown, the invention discloses a preparation method of an n-type tin telluride thermoelectric material, comprising the following steps:

[0045] Step 1, combine Sn, Te, Pb and SnI 2 The molar ratio is: (1-x-y), (1-2y), x and y are mixed to obtain a mixed material, wherein, 0.26<x<0.5, 0.002<y.

[0046] Step 2, putting the mixed material into a quartz tube and vacuumizing it.

[0047] Step 3, placing the quartz tube containing the mixed material in a heat treatment furnace for heat treatment and synthesis reaction to obtain an n-type SnTe ingot, wherein the heat treatment furnace can be a muffle furnace or other heat treatment furnace that can be heated and heated.

[0048] Step 4, grinding the n-type SnTe ingot into powder, and putting it into a graphite mold for sintering to obtain an n-type SnTe sample.

[0049] Also disclosed is an n-type tin telluride thermoelectric material comprising Pb and SnI 2 ; Sn, Te, Pb and SnI 2 The molar ratio of...

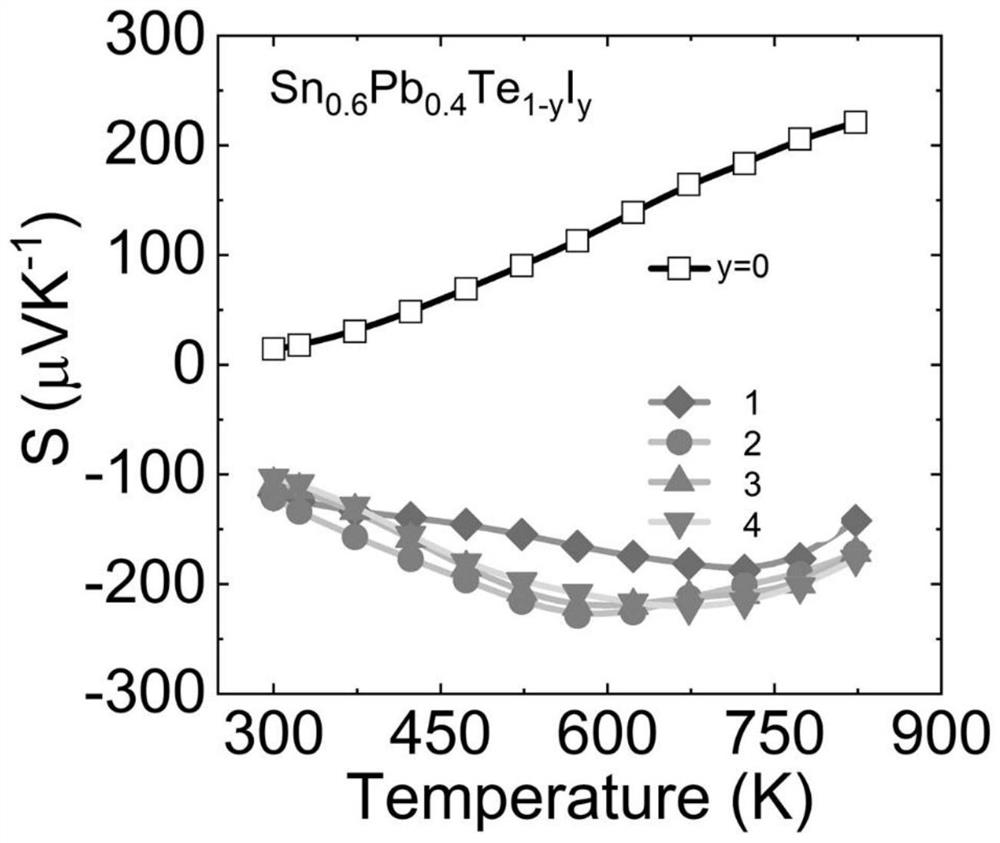

Embodiment 1

[0055] According to the molar ratio of Sn, Pb, Te and I is the proportioning of 0.6:0.4:0.99:0.01, the Sn, Te, Pb and SnI with purity greater than 99.99% 2 The blocks are mixed to obtain a mixed material.

[0056] Put the mixed material into a quartz tube (10 mm in diameter), fill it with argon, and circulate it for 3 times, then vacuumize and seal the inner quartz tube until the vacuum degree of the inner quartz tube is less than 10 -3 Pa, the quartz tube was sealed with a flame.

[0057] Place the quartz tube filled with the mixture in a muffle furnace for heat treatment, and set the temperature control program of the muffle furnace: raise the temperature to 450°C at a rate of 35°C / h; then raise the temperature to 1150°C at a rate of 10°C / h , keep warm for 720min; then cool to room temperature with the furnace. High-quality n-type SnTe ingots are obtained after heat treatment.

[0058] Grind the high-quality n-type SnTe ingot obtained after heat treatment into powder and ...

Embodiment 2

[0060] According to the molar ratio of Sn, Pb, Te and I is the proportioning of 0.6:0.4:0.985:0.015, the Sn, Te, Pb and SnI with purity greater than 99.99% 2 The blocks are mixed to obtain a mixed material.

[0061] Put the mixed material into a quartz tube (10 mm in diameter), fill it with argon, and circulate it for 3 times, then vacuumize and seal the inner quartz tube until the vacuum degree of the inner quartz tube is less than 10 -3 Pa, the quartz tube was sealed with a flame.

[0062] Place the quartz tube filled with the mixture in a muffle furnace for heat treatment, and set the temperature control program of the muffle furnace: raise the temperature to 450°C at a rate of 35°C / h; then raise the temperature to 1150°C at a rate of 10°C / h , keep warm for 720min; then cool to room temperature with the furnace. High-quality n-type SnTe ingots are obtained after heat treatment.

[0063] Grind the high-quality n-type SnTe ingot obtained after heat treatment into powder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com