A kind of n-type tin telluride thermoelectric material and preparation method thereof

A thermoelectric material, tin telluride technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc., can solve the problem that Sn vacancies are difficult to eliminate, n-type tin telluride synthesis technology and performance reports and research, It is difficult to realize n-type tin telluride and other problems to achieve the effect of optimal thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Such as Figure 18 As shown, the invention discloses a preparation method of an n-type tin telluride thermoelectric material, comprising the following steps:

[0045] Step 1, combine Sn, Te, Pb and SnI 2 The molar ratio is: (1-x-y), (1-2y), x and y are mixed to obtain a mixed material, wherein, 0.26

[0046] Step 2, putting the mixed material into a quartz tube and vacuumizing it.

[0047] Step 3, placing the quartz tube containing the mixed material in a heat treatment furnace for heat treatment and synthesis reaction to obtain an n-type SnTe ingot, wherein the heat treatment furnace can be a muffle furnace or other heat treatment furnace that can be heated and heated.

[0048] Step 4, grinding the n-type SnTe ingot into powder, and putting it into a graphite mold for sintering to obtain an n-type SnTe sample.

[0049] Also disclosed is an n-type tin telluride thermoelectric material comprising Pb and SnI 2 ; Sn, Te, Pb and SnI 2 The molar ratio of...

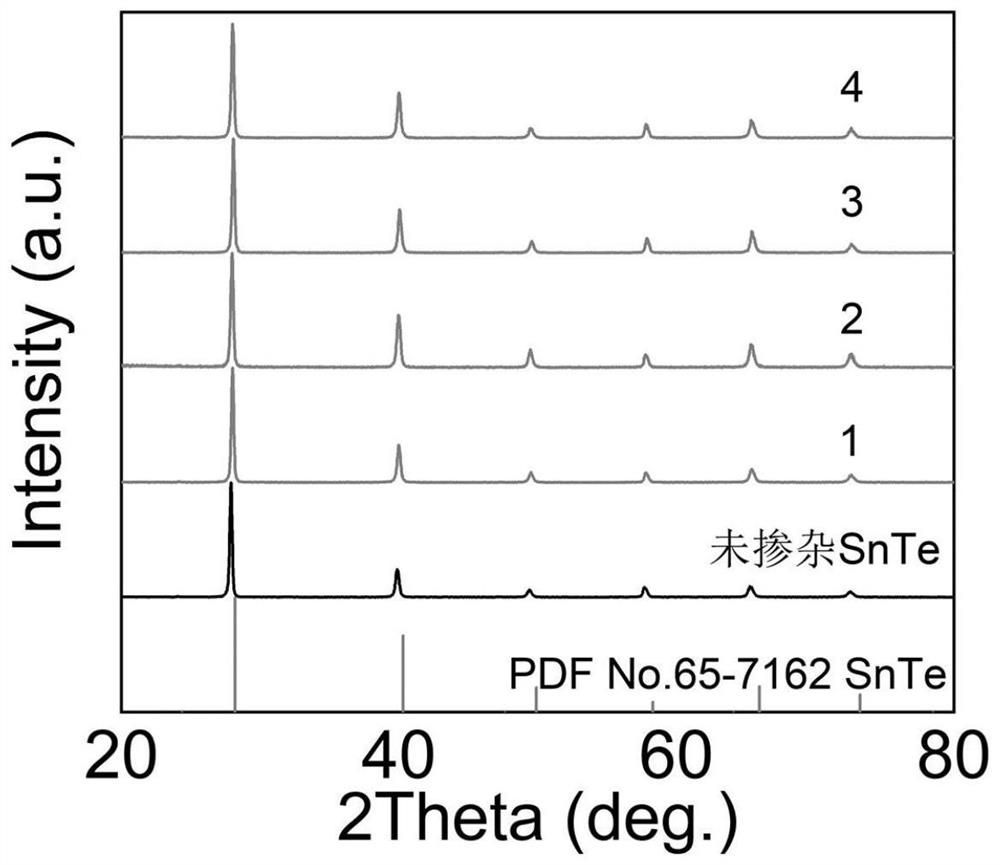

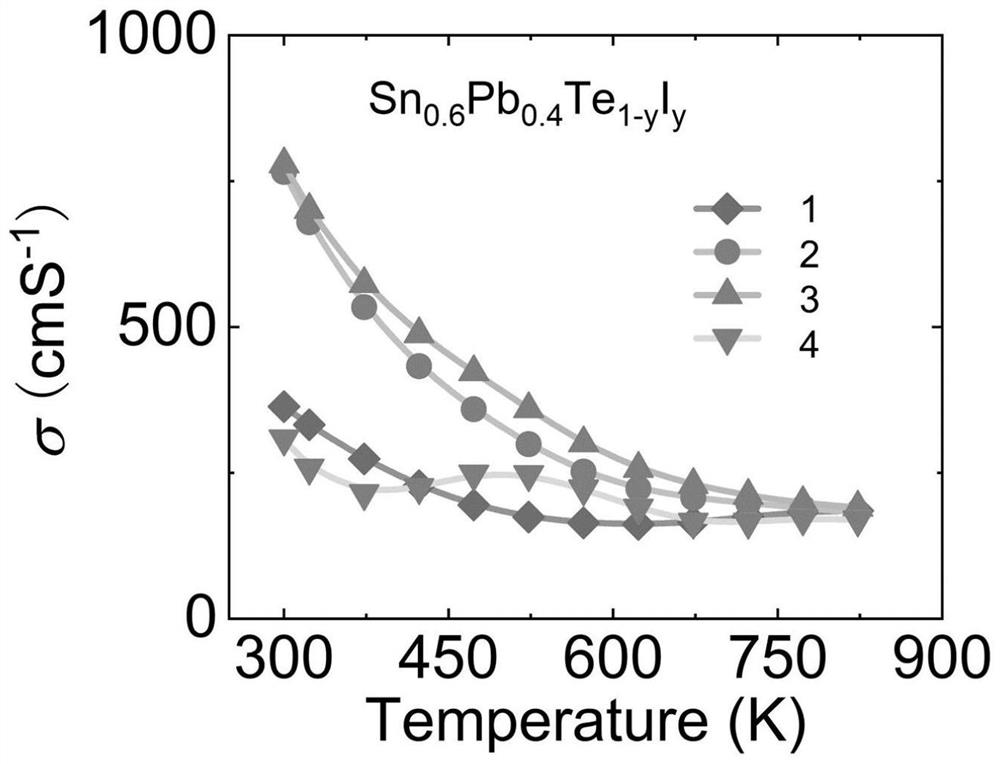

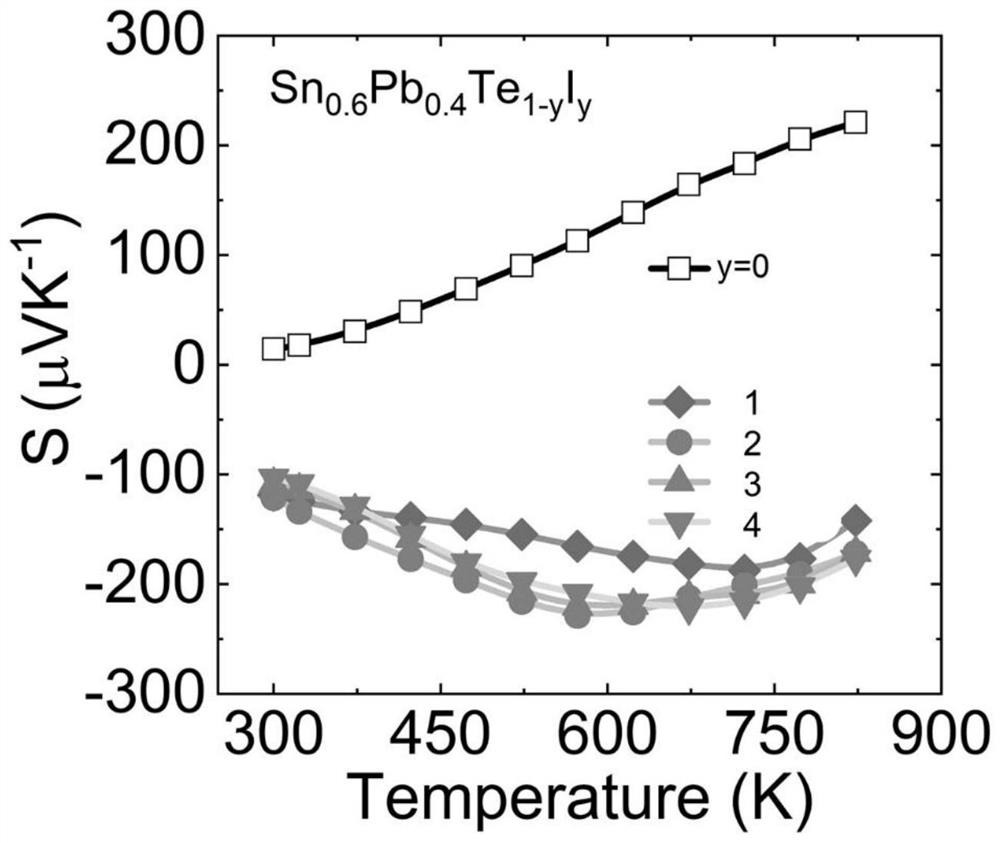

Embodiment 1

[0055] According to the molar ratio of Sn, Pb, Te and I is the proportioning of 0.6:0.4:0.99:0.01, the Sn, Te, Pb and SnI with purity greater than 99.99% 2 The blocks are mixed to obtain a mixed material.

[0056] Put the mixed material into a quartz tube (10 mm in diameter), fill it with argon, and circulate it for 3 times, then vacuumize and seal the inner quartz tube until the vacuum degree of the inner quartz tube is less than 10 -3 Pa, the quartz tube was sealed with a flame.

[0057] Place the quartz tube filled with the mixture in a muffle furnace for heat treatment, and set the temperature control program of the muffle furnace: raise the temperature to 450°C at a rate of 35°C / h; then raise the temperature to 1150°C at a rate of 10°C / h , keep warm for 720min; then cool to room temperature with the furnace. High-quality n-type SnTe ingots are obtained after heat treatment.

[0058] Grind the high-quality n-type SnTe ingot obtained after heat treatment into powder and ...

Embodiment 2

[0060] According to the molar ratio of Sn, Pb, Te and I is the proportioning of 0.6:0.4:0.985:0.015, the Sn, Te, Pb and SnI with purity greater than 99.99% 2 The blocks are mixed to obtain a mixed material.

[0061] Put the mixed material into a quartz tube (10 mm in diameter), fill it with argon, and circulate it for 3 times, then vacuumize and seal the inner quartz tube until the vacuum degree of the inner quartz tube is less than 10 -3 Pa, the quartz tube was sealed with a flame.

[0062] Place the quartz tube filled with the mixture in a muffle furnace for heat treatment, and set the temperature control program of the muffle furnace: raise the temperature to 450°C at a rate of 35°C / h; then raise the temperature to 1150°C at a rate of 10°C / h , keep warm for 720min; then cool to room temperature with the furnace. High-quality n-type SnTe ingots are obtained after heat treatment.

[0063] Grind the high-quality n-type SnTe ingot obtained after heat treatment into powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com