Preparation method of Ni-B/B4C nano composite plating through pulse electrodeposition

A technology of pulse electrodeposition and nano-composite, applied in the direction of coating, electrolytic coating, etc., can solve the problems of general wear resistance, high hardness and high corrosion resistance, etc., to improve hardness, enhance wear resistance, Effect of High Elastic Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of Ni-B / B 4 The preparation method of C nanocomposite coating film:

[0038] (1) Pretreatment of the substrate

[0039] The steel sheet is derusted by grinding with sandpaper, then degreased by ultrasonic cleaning, and finally activated by pickling. The cleaning agent for degreasing the substrate is an aqueous solution, and the concentration of each component in the aqueous solution is: sodium hydroxide 50g / L, sodium carbonate 40g / L, sodium phosphate 40g / L, OP-10 emulsifier 5ml / L, temperature 70°C , Time 10min. Pickling activation: use 1mol / L dilute sulfuric acid at room temperature for 30s.

[0040] (2) Preparation of electroplating solution

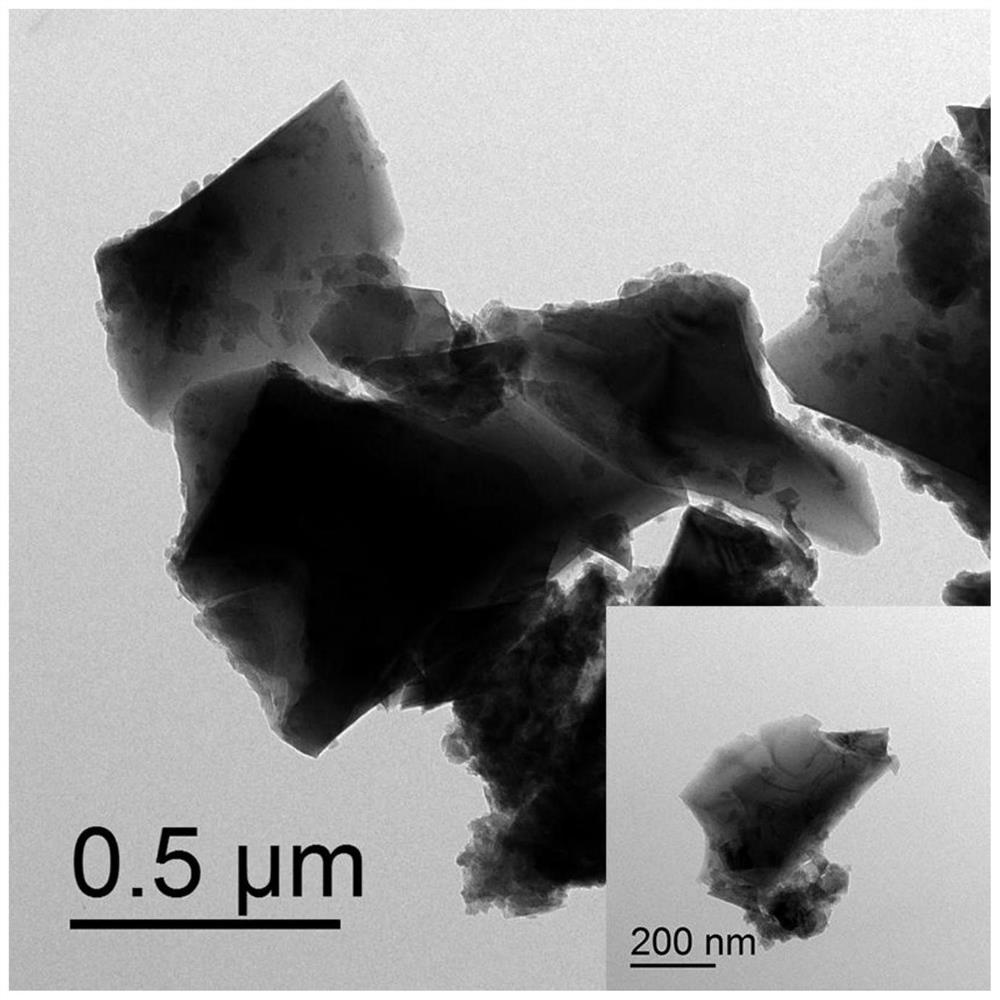

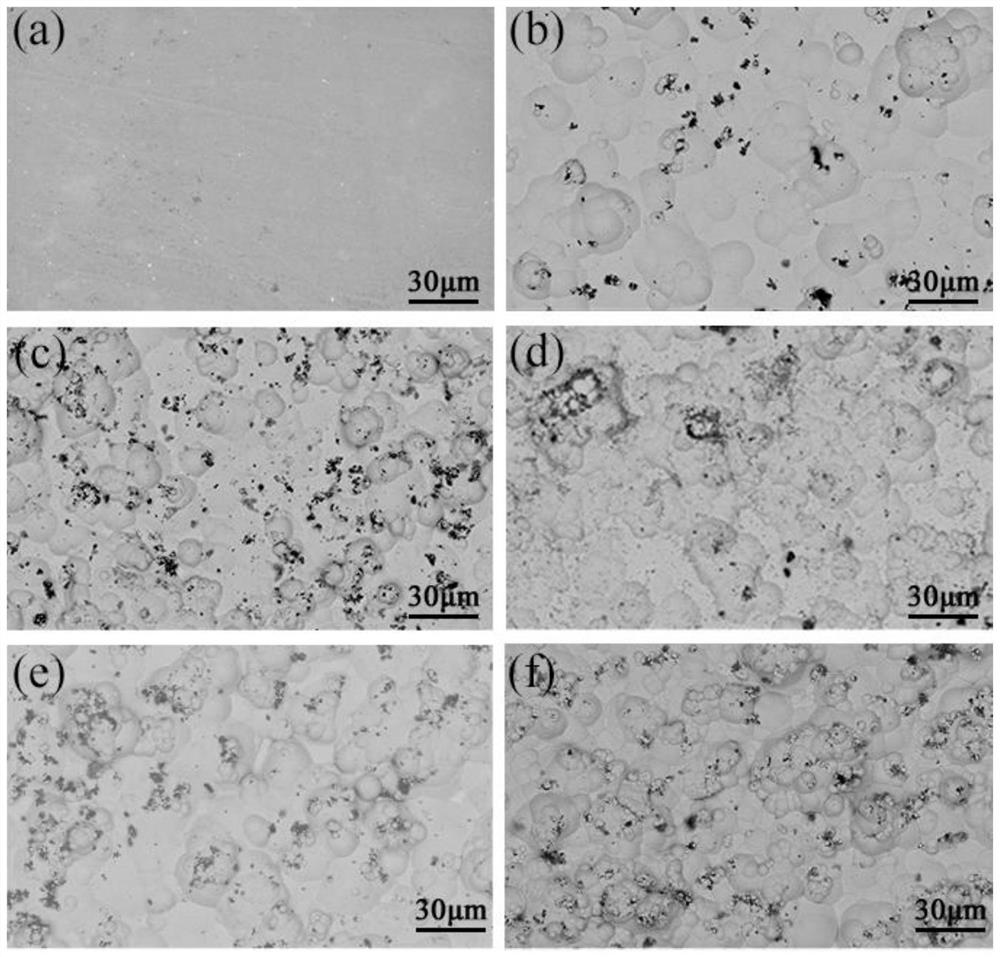

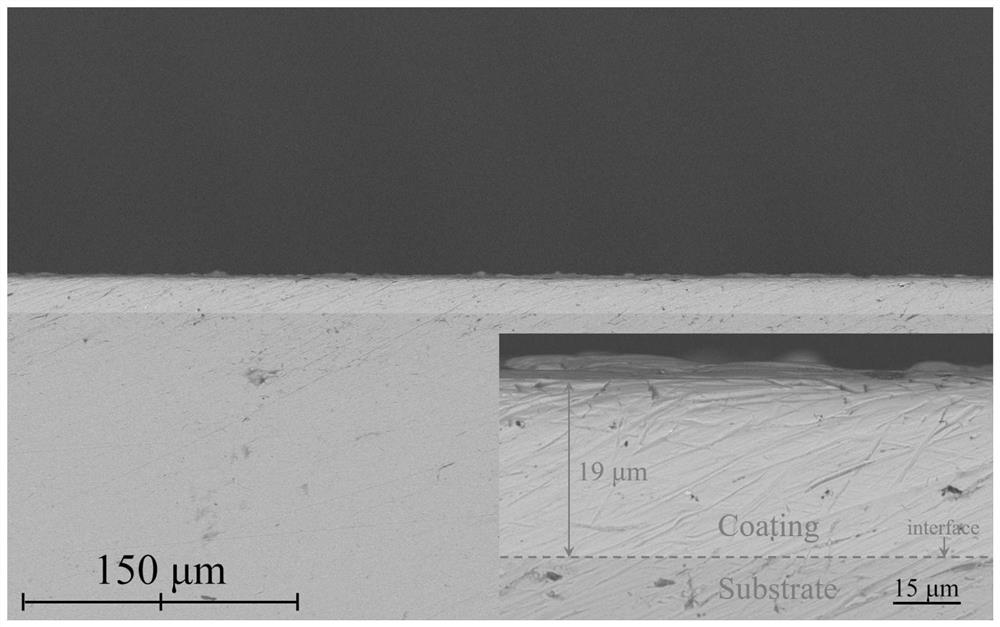

[0041]Ni-B / B 4 The components of C composite plating solution are: nickel sulfate 240g / L, nickel chloride 45g / L, boric acid 30g / L, saccharin 0.5g / L, dimethylamine borane 3g / L, surfactant (SDS) 0.1g / L,B 4 C nanoparticles 1g / L. After the electroplating solution was prepared, it was mechanically stirred for 30 minute...

Embodiment 2

[0046] A kind of Ni-B / B 4 The preparation method of C nanocomposite coating film, step is with embodiment 1, difference is: in electroplating solution, B 4 C nanoparticles 2g / L. Coating sample 3 was obtained.

Embodiment 3

[0048] A kind of Ni-B / B 4 The preparation method of C nanocomposite coating film: step is with embodiment 1, difference is: in electroplating solution, B 4 C nanoparticles 3g / L. The coating sample 4 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com