Ultrasmall type voice coil motor

A voice coil motor, voice coil technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of limited application, etc., to simplify the installation process, save welding steps, and reduce the radial and axial dimensions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

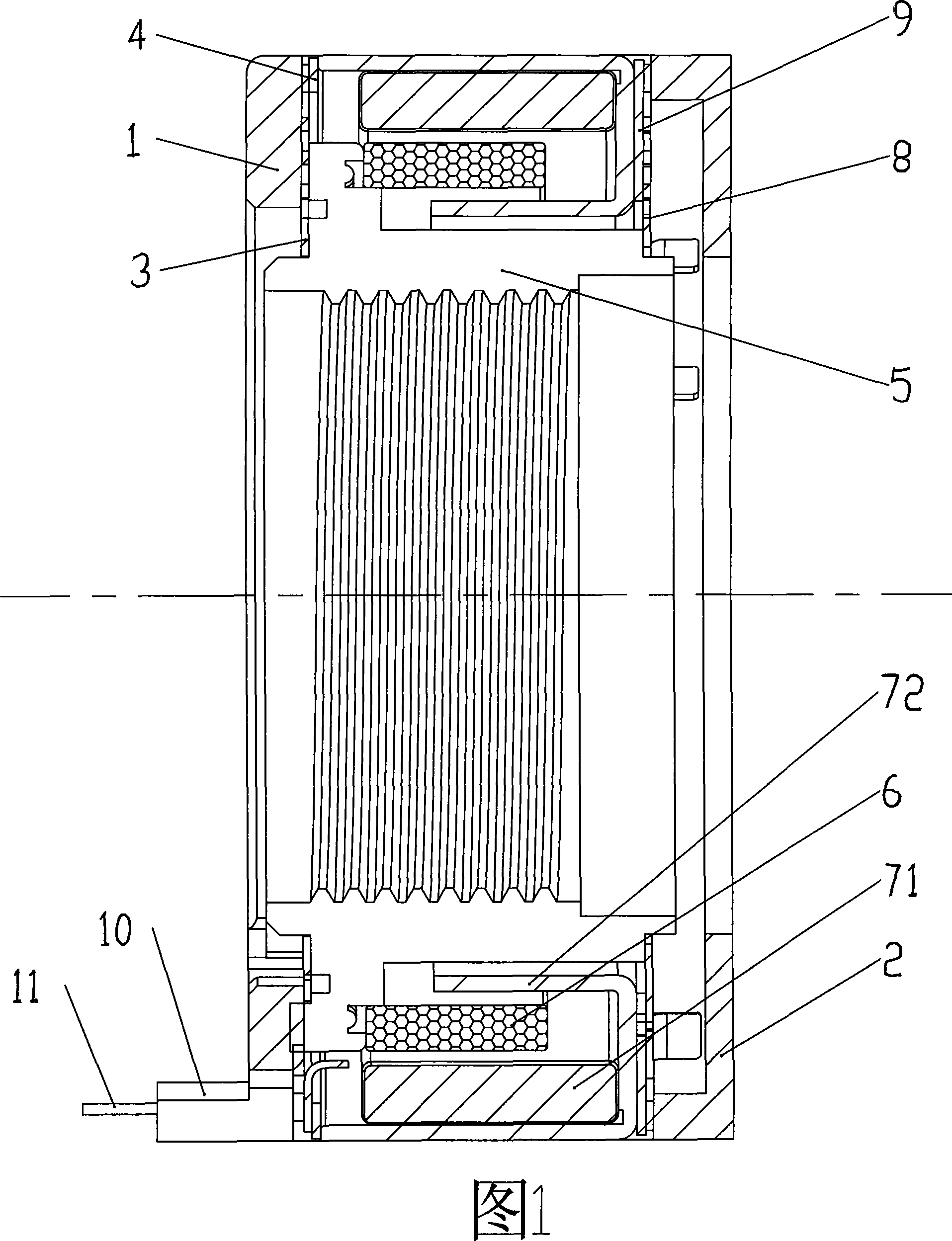

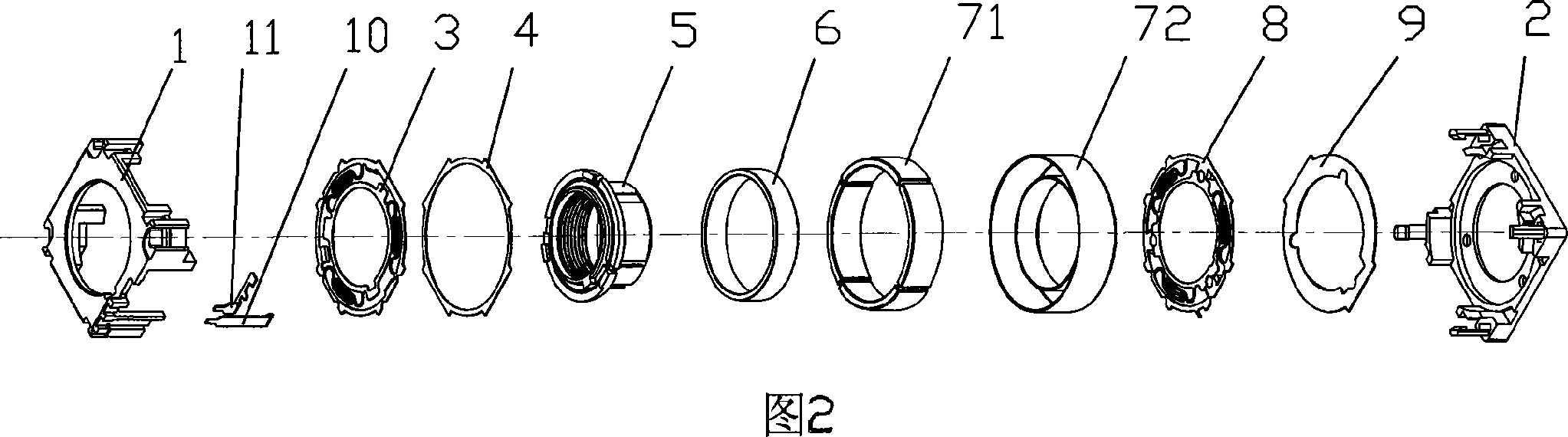

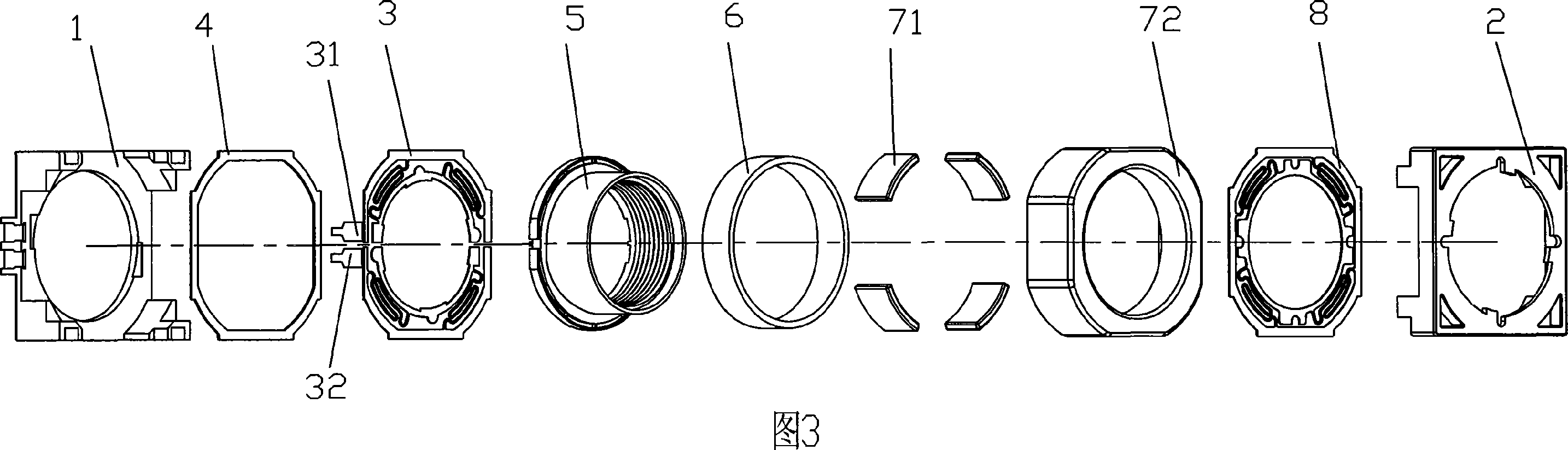

[0024] A specific embodiment of the present invention will be described below in conjunction with accompanying drawings 3-9. As shown in FIG. 3 , the present invention includes: casings 1 and 2 , a moving base 5 , a conductive coil 6 , a permanent magnet unit 7 and split front and rear spring pieces 8 and 3 . The insulating sheet 4 is disposed between the metal case 72 and the rear spring 3 . Four pieces of 40-degree arc-shaped permanent magnets 71 are arranged in a rectangular metal shell 72 with arc-shaped chamfers to form a permanent magnet unit 7; It is clamped and installed in the metal shell 72 ; the ring-shaped conductive coil 6 is wound by a thermosetting high-temperature self-adhesive copper wire, and is fixed on the moving support 5 through a sleeve. Its mechanical position is located in the outer gap formed by the magnet 71 and the outer wall of the housing 72 . In this way, a closed magnetic circuit that starts from the N pole of the magnet 71, passes through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com