Graphene conductive ink, graphene conductive film and preparation methods and applications thereof

A technology of conductive ink and graphene, which is applied in the direction of equipment, ink, and application for manufacturing conductive/semiconductive layers, and can solve problems such as cumbersome process, unfavorable industrial application, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

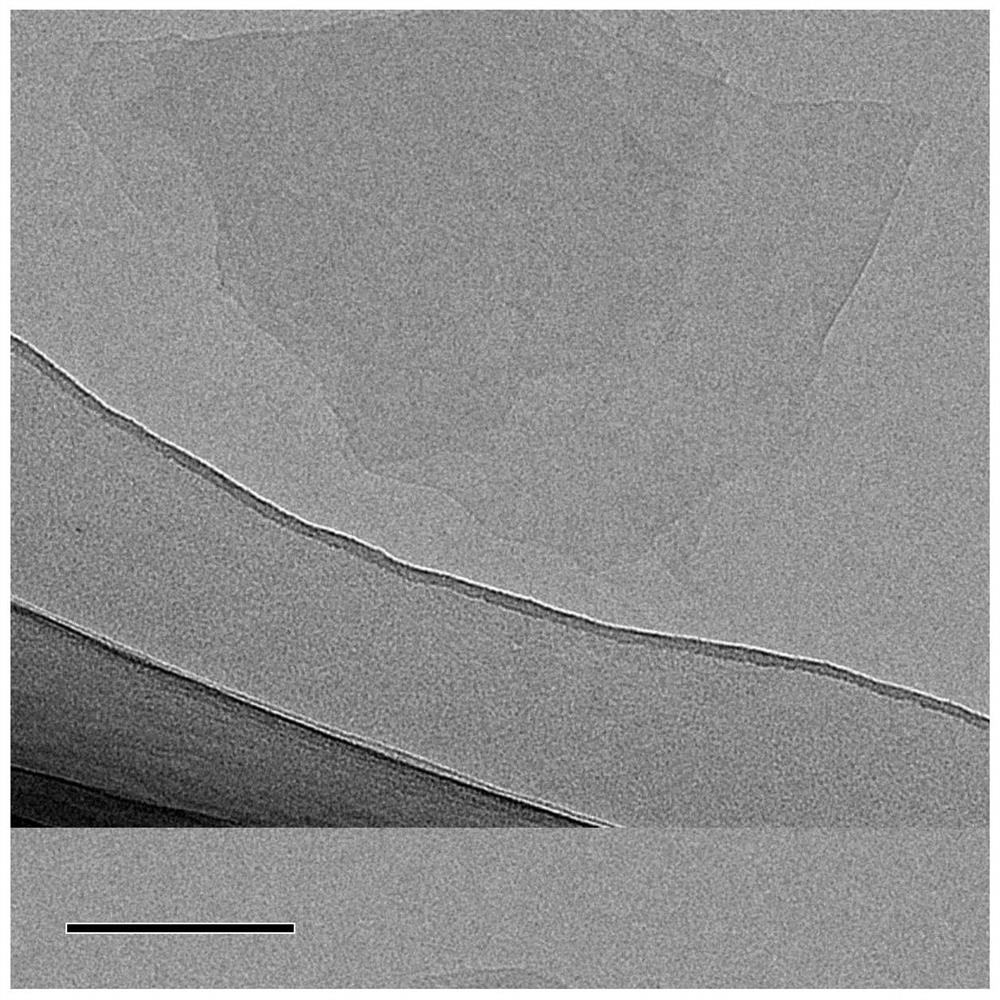

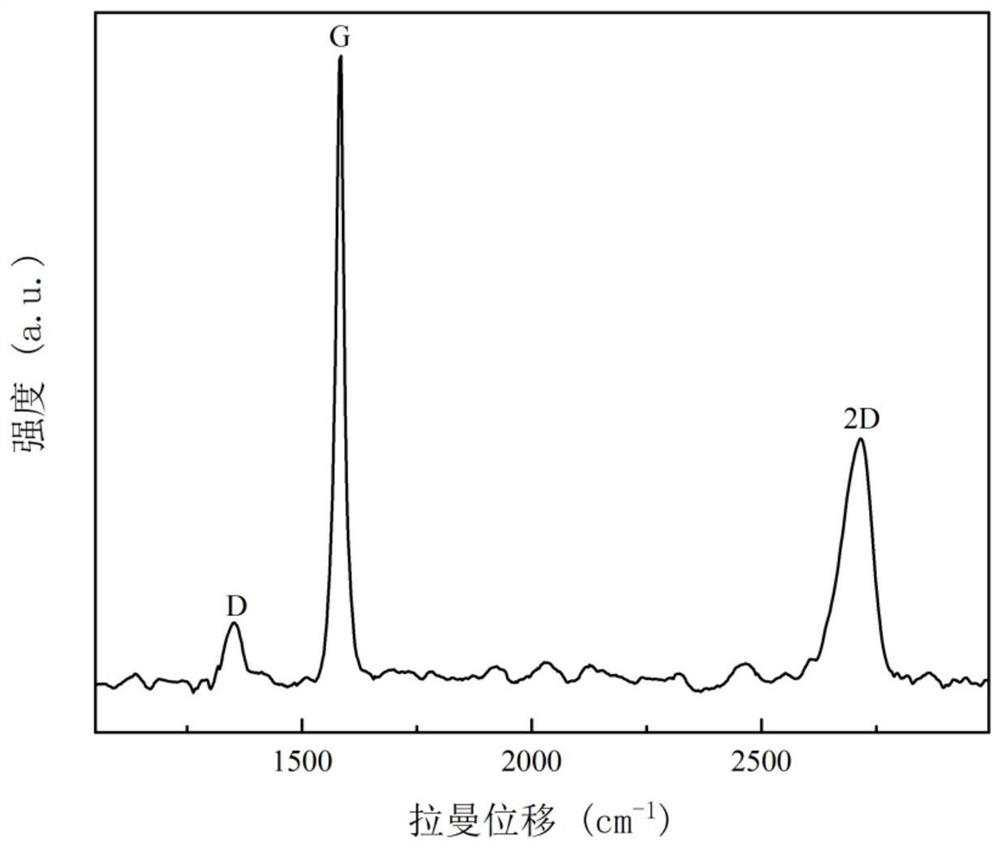

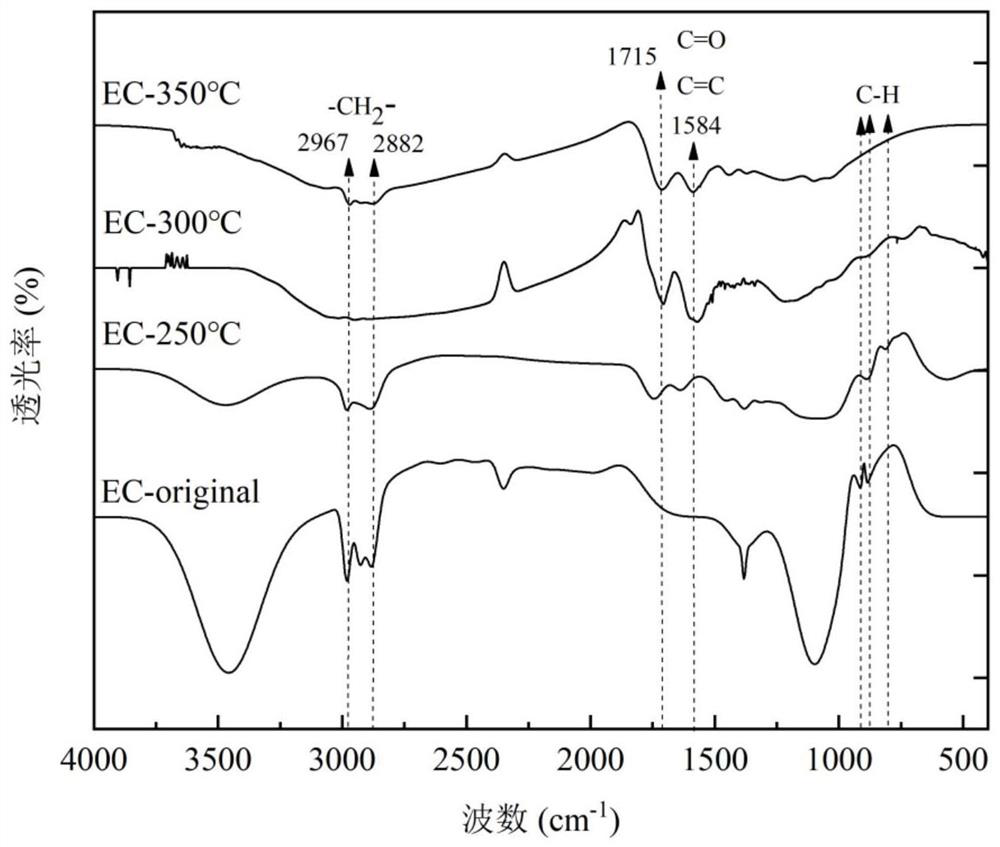

[0062] Mix and stir ethanol and ethyl cellulose to prepare 300 mL of ethyl cellulose / ethanol solution with a concentration of 10 mg / mL; then weigh 15 g of scaly natural graphite and add it to the above ethyl cellulose / ethanol solution. A homogeneous emulsifier was used to shear and mix the above mixed solution for 60 min at a speed of 1000 rpm to obtain a pretreated graphite dispersion. The initial pre-treated graphite dispersion is added to the feed cup of the high-pressure micro-jet homogenizer, first circulated 10 times through the 300μm nozzle, and the pressure is 8000psi; then circulated 40 times through the 180μm nozzle, the pressure is 20000psi. After the high-pressure peeling action of the high-pressure pump, the graphene dispersion is obtained. In order to remove larger and incompletely peeled sheets, the graphene dispersion was centrifuged at a speed of 500 rpm for 10 min to collect the upper dispersion. The upper dispersion liquid is a uniform graphene conductive i...

Embodiment 2

[0065] Mix and stir ethanol and ethyl cellulose to prepare 300 mL of ethyl cellulose / ethanol solution with a concentration of 10 mg / mL; then weigh 9 g of worm-like expanded graphite and add it to the above ethyl cellulose / ethanol solution. Use a homogeneous emulsifier to shear and mix the above mixed solution for 60 minutes at a speed of 1000 rpm to obtain a pretreated graphite dispersion. The initial pre-treated graphite dispersion is added to the feed cup of the high-pressure micro-jet homogenizer, first circulated 10 times through the 300μm nozzle, and the pressure is 8000psi; then circulated 40 times through the 180μm nozzle, the pressure is 20000psi. After the high-pressure peeling action of the high-pressure pump, the graphene dispersion is obtained. In order to remove larger and incompletely peeled sheets, the graphene dispersion was centrifuged at a speed of 500 rpm for 10 min to collect the upper dispersion. The upper dispersion liquid is a uniform graphene conductiv...

Embodiment 3

[0068] Mix and stir ethanol and ethyl cellulose to prepare 300 mL of ethyl cellulose / ethanol solution with a concentration of 30 mg / mL; then weigh 15 g of scaly natural graphite and add it to the above ethyl cellulose / ethanol solution. Use a homogeneous emulsifier to shear and mix the above mixed solution for 60 minutes at a speed of 1000 rpm to obtain a pretreated graphite dispersion. The initial pre-treated graphite dispersion is added to the feed cup of the high-pressure micro-jet homogenizer, first circulated 10 times through the 300μm nozzle, and the pressure is 8000psi; then circulated 40 times through the 180μm nozzle, the pressure is 20000psi. After the high-pressure peeling action of the high-pressure pump, the graphene dispersion is obtained. In order to remove larger and incompletely peeled sheets, the graphene dispersion was centrifuged at a speed of 500 rpm for 5 min to collect the upper dispersion. The upper dispersion liquid is a uniform graphene conductive ink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com