Light-emitting diode (LED) packaging silica gel and preparation method thereof

A technology of LED encapsulation and silica gel, which is applied in adhesives, electrical components, circuits, etc., can solve the problems of encapsulation failure, poor aging resistance, and poor high and low temperature resistance, and achieves simple and easy preparation process, good storage stability, Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

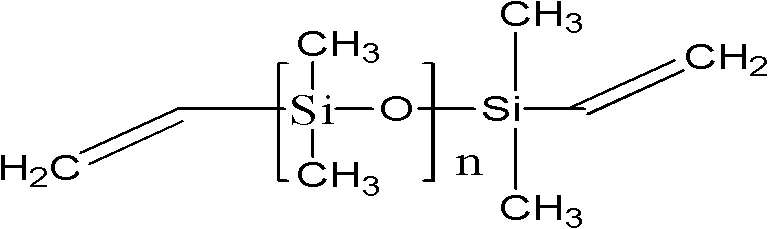

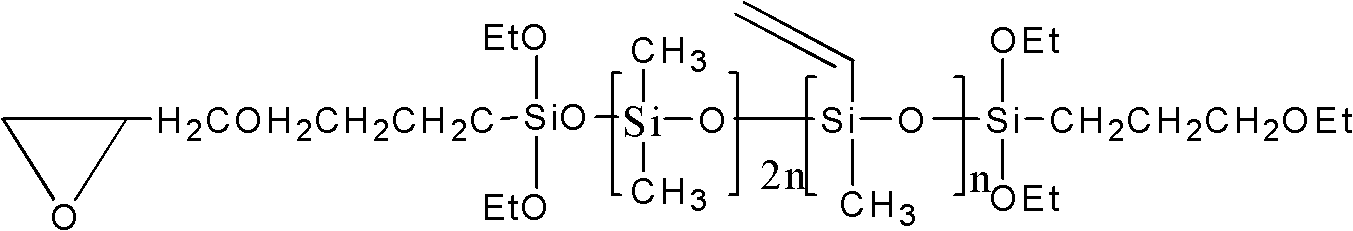

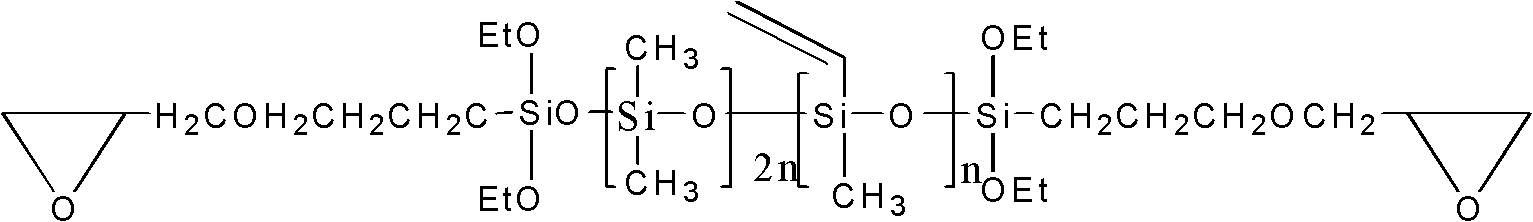

[0034] Preparation of component A: Weigh 95g of vinyl polydisiloxane, 5g of adhesive (structural formula 1), 0.1g of catalyst platinum-vinylsiloxane complex with a content of 7000ppm, add them to the mixer in turn, and fill Nitrogen with a concentration of 99.9%, mixed and stirred evenly to obtain the A component;

[0035] Preparation of component B: Weigh 85g of vinyl polydisiloxane, 15g of crosslinking agent polymethylhydrogensiloxane, and 0.2g of inhibitor ethynyl cyclohexanol, add them to the mixer in sequence, and fill them with a concentration of 99.9 % nitrogen, mixed and stirred evenly to obtain the B component;

[0036] When in use, mix the components A and B evenly in a weight ratio of 1:1, vacuum defoam for 20 minutes, dispense or pour glue on the parts to be packaged, and heat at 90°C for 1.5 hours , and then heated at 100°C for 2.5 hours.

Embodiment 2

[0038] Preparation of component A: Weigh 96g of vinyl polydisiloxane, 3g of adhesive (structural formula 2), 0.3g of catalyst platinum-vinylsiloxane complex with a content of 3000ppm, add them to the mixer in turn, and fill Nitrogen with a concentration of 99.9%, mixed and stirred evenly to obtain the A component;

[0039] Preparation of component B: Weigh 95g of vinyl polydisiloxane, 5g of crosslinking agent polymethylhydrogensiloxane, and 0.3g of inhibitor ethynyl cyclohexanol, add them to the mixer in sequence, and fill them with a concentration of 99.9 % nitrogen, mixed and stirred evenly to obtain the B component;

[0040] When in use, mix the components A and B evenly in a weight ratio of 1:1, vacuum defoam for 40 minutes, dispense or pour glue on the parts to be packaged, and heat at 70°C for 0.5 hours , and then heated at 200°C for 1.5 hours.

Embodiment 3

[0042] Preparation of component A: Weigh 95.8g of vinyl polydisiloxane, 4g of adhesive (structural formula 1), 0.2g of catalyst platinum-vinylsiloxane complex with a content of 6000ppm, add them to the mixer in turn, and fill Inject nitrogen with a concentration of 99.9%, mix and stir evenly to obtain the A component;

[0043] Preparation of component B: Weigh 89.8g of vinyl polydisiloxane, 10g of crosslinking agent polymethylhydrogensiloxane, and 0.1g of inhibitor ethynyl cyclohexanol, add them to the mixer in sequence, and fill them with a concentration of 99.9% nitrogen, mixed and stirred evenly to obtain the B component;

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com