Multi-shape- shape- memory driven intelligent optical film with multi-structural color conversion, and preparation method and application of multi-shape shape memory driven intelligent optical film with multi-structural color conversion

A multi-structure, optical film technology, applied in optics, optical components, instruments, etc., can solve problems such as a single stimulation method, achieve the effect of improving flexibility, simple and controllable preparation process, and solving easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

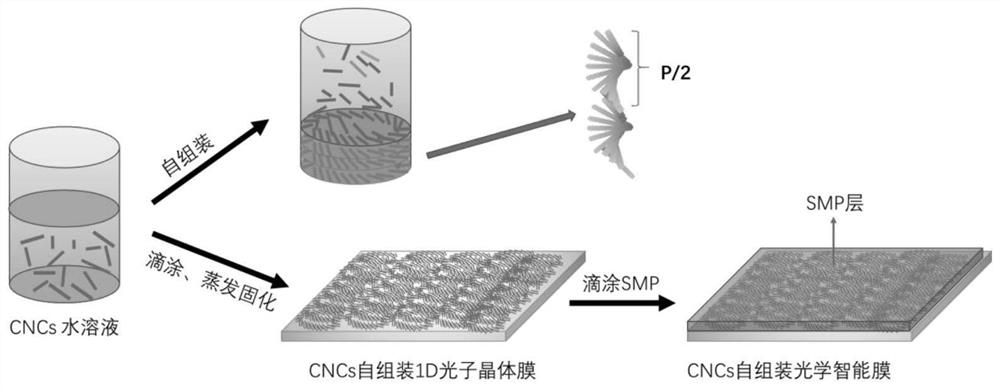

[0038] 1. Dissolve cellulose nanocrystal (CNCs) powder in deionized water, configure it into an aqueous solution with a mass fraction of 3%, disperse it ultrasonically for 2 hours at room temperature, and adjust the pH value to 5-7 to prepare cellulose nanocrystal suspension solution; take 0.5ml of CNCs dispersion liquid and apply it on the glass substrate, slowly dry it at room temperature for 2 days, induce the evaporation of water, and then form a translucent self-assembled ordered structure, and prepare a self-assembled cellulose nanocrystalline film .

[0039] 2. Dissolving amorphous polymer Tg shape memory polyurethane in N,N-dimethylformamide to form a solution with a mass fraction of 20%. Take 5ml of the solution from a needle tube and evenly drop-coat it onto the surface of the self-assembled cellulose nanocrystalline film, and cure it at 60°C for 2 hours under vacuum to prepare a polymorphic shape memory-driven multi-structural color transition intelligent optical fi...

Embodiment 2

[0043] 1. Dissolve the cellulose nanocrystalline powder in deionized water to prepare a suspension solution with a mass fraction of 5%, ultrasonically disperse it at room temperature for 2 hours, and adjust the pH value to 5-7. Take 2ml of the CNCs suspension and drop-coat it on the glass substrate, slowly dry it at room temperature for 2 days, induce the evaporation of water to form a translucent self-assembled ordered structure, and prepare the self-assembled cellulose nanocrystalline film.

[0044] 2. Dissolving amorphous polymer Tg shape memory polyurethane in N,N-dimethylformamide to form a solution with a mass fraction of 20%. Take 5ml of the solution from a needle tube and evenly drop-coat it onto the surface of the self-assembled cellulose nanocrystalline film, place it in an oven, and cure it at 60°C for 2 hours under vacuum to prepare a smart optical film driven by multiple shape memory.

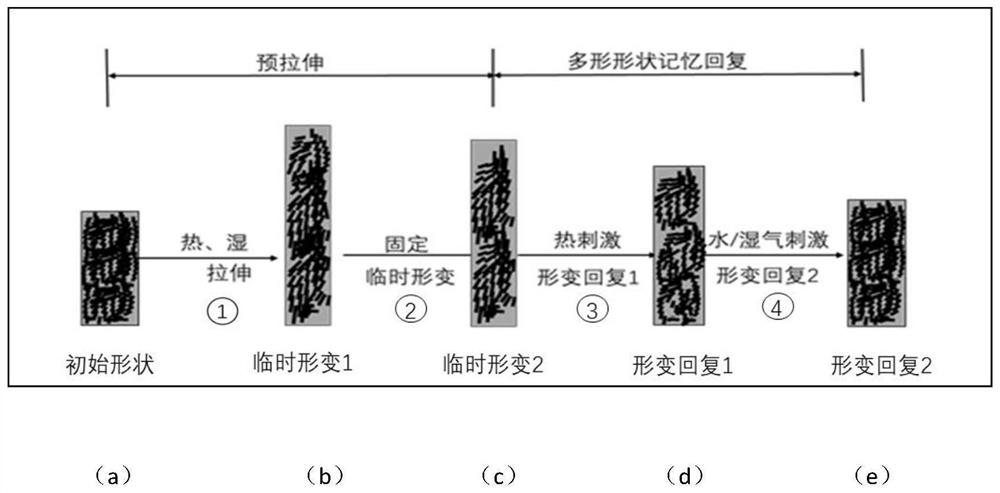

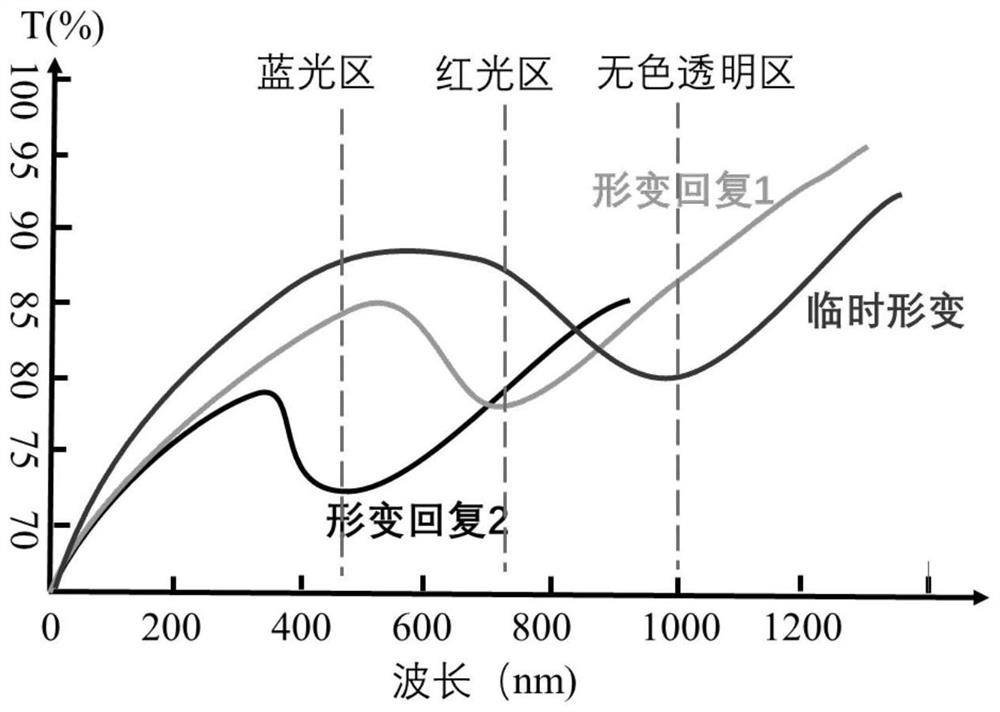

[0045] After immersing the smart optical film in hot water at 90° C. for 1 min...

Embodiment 3

[0047] 1. Dissolve the cellulose nanocrystalline powder in deionized water to prepare a suspension solution with a mass fraction of 5%, ultrasonically disperse it at room temperature for 2 hours, and adjust the pH value to 5-7. Take 2ml of the CNCs suspension and drop-coat it on the glass substrate, slowly dry it at room temperature for 2 days, induce the evaporation of water to form a translucent self-assembled ordered structure, and prepare the self-assembled cellulose nanocrystalline film.

[0048] 2. Dissolving amorphous polymer Tg shape memory polyurethane in N,N-dimethylformamide organic solvent to form a solution with a mass fraction of 20%. Take 5ml of the solution from a needle tube and evenly drop-coat it onto the surface of the CNCs self-assembled film, place it in an oven, and cure it at 60°C for 2 hours under vacuum to prepare a smart optical film driven by multiple shape memory.

[0049] After immersing the smart optical film in hot water at 90° C. for 3 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com