Integrated normal-closed PDMS micro-valve, preparation process thereof and micro-pump containing micro-valve

A preparation process and microvalve technology, applied in the field of microfluidics, can solve problems such as unfavorable preparation cost and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

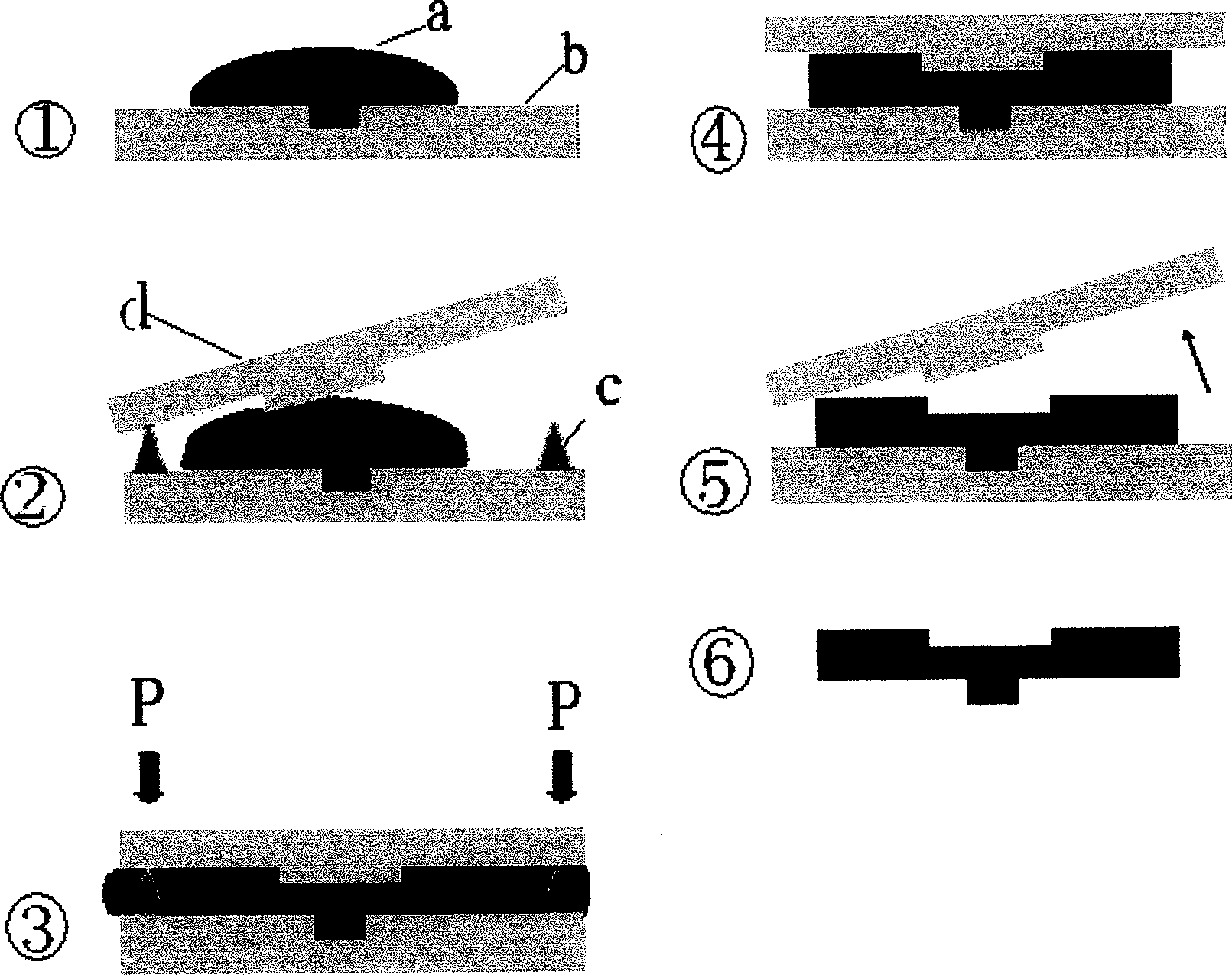

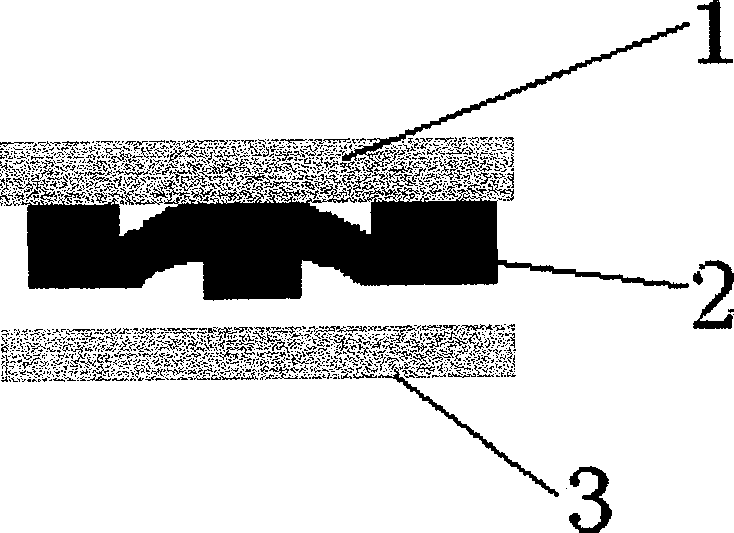

[0023] according to figure 2 The described procedure prepares an integrated normally closed PDMS microvalve. The whole preparation process is described as follows;

[0024] ①. Pouring the PDMS mixed at 10:1 on the glass containing the fluid channel mold. The fluid channel mold is formed by developing SU-8 glue and silanized to remove air bubbles.

[0025] ②. Cover another piece of glass containing the gas channel mold (the fluid channel mold is formed by developing SU-8 glue or chrome glass through photolithography, development, etching, and silanization treatment) on the PDMS.

[0026] ③. The distance between the gas channel mold glass and the fluid channel mold glass is 100-500 microns, and they are aligned. Pressure is then applied to squeeze out excess PDMS.

[0027] ④ Put it in an oven at 80 degrees for 1 hour to make PDMS completely solidify.

[0028] ⑤. Along the edge of a piece of glass, lift it up gently to separate the glass from PDMS.

[0029] ⑥. Separate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com