A jig and method for laser cutting of aerospace titanium alloy

A technology of laser cutting and laser cutting head, which is applied in the field of parts processing, can solve the problems that the assembled cutting fixture does not have a fixed function, the laser cutting head collides with the part, the cutting fixture, affects the production progress and delivery cycle of the part, and shortens the delivery cycle, ensure processing quality, save the effect of grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

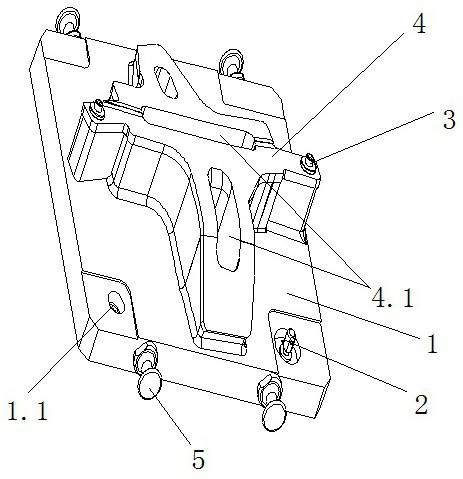

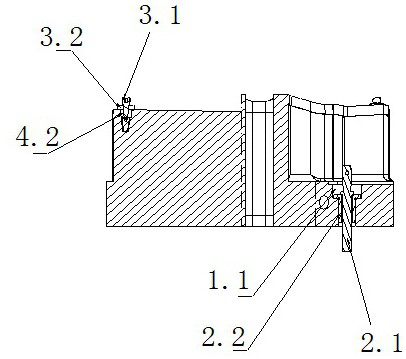

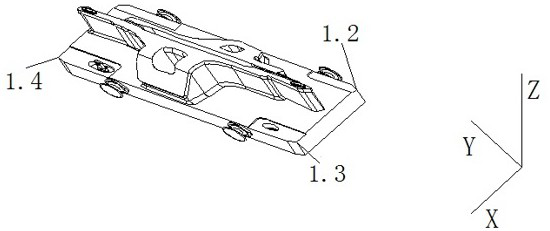

[0057] This embodiment discloses a kind of aerospace titanium alloy laser cutting fixture, as a kind of basic embodiment of the present invention, such as figure 1 The schematic diagram of the overall structure of the cutting fixture is shown, including a base plate base 1, at least two clamp positioning parts 2 and at least two part positioning parts 3; the base plate base 1 is provided with clamps corresponding to the clamp positioning parts 2 one by one The positioning hole 1.1, the top of the bottom plate base 1 is provided with a profile protrusion 4 for supporting titanium alloy parts, and the profile protrusion 4 is provided with a part positioning hole 4.2 corresponding to the part positioning part 3 one-to-one.

[0058] In the actual production of this technical solution, based on the simple composition structure of the cutting jig, cast aluminum can be used as the manufacturing material of the cutting jig. In this way, the cutting jig is lighter in weight and has bett...

Embodiment 2

[0060] This example discloses an aviation titanium alloy laser cutting jig, as a preferred embodiment of the present invention, that is, in Example 1, since the titanium alloy parts are generally large parts, the cutting jigs needed are generally larger in size , Therefore, the aforementioned "light weight of the jig" is only relative to ordinary jigs (such as the simple splicing jigs in the prior art) or cutting jigs made of other materials. Aside from these comparisons, the weight of the cutting jig itself is relatively It is heavy, and it is troublesome to carry it by hand. Therefore, it is necessary to use a crane for auxiliary transportation. In order to increase the focus of transportation, four lifting rings 5 are arranged on the base plate base 1, and the four lifting rings 5 are evenly distributed on the base plate base. Both sides of the seat 1 are arranged in a rectangular structure as a whole. During use, use a crane to hang four nylon belt hooks, hang the hook...

Embodiment 3

[0062] This example discloses an aviation titanium alloy laser cutting jig, as a preferred embodiment of the present invention, that is, in Example 1, since the titanium alloy parts are generally large parts, the cutting jigs needed are generally larger in size , Therefore, the aforementioned "light weight of the jig" is only relative to ordinary jigs (such as the simple splicing jigs in the prior art) or cutting jigs made of other materials. Aside from these comparisons, the weight of the cutting jig itself is relatively Heavy, therefore, a hollow structure 4.1 is provided in the middle region of the profile protrusion 4 . The setting of the hollow structure 4.1 can save the use of some materials, reduce the cost of materials and make the cutting jig more portable under the condition that the titanium alloy parts are not deformed and concave due to gravity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com