Super-hydrophobic molybdenum-loaded catalyst as well as preparation method and application thereof

A catalyst and super-hydrophobic technology, applied in the direction of catalyst carrier, preparation/separation of ammonia, chemical instruments and methods, etc., can solve the problems that nitrogen in ammonia is difficult to adsorb, activate hydrogen evolution competition reaction, and dominate, so as to improve Faradaic efficiency and cost Low, the effect of inhibiting the competition reaction of hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

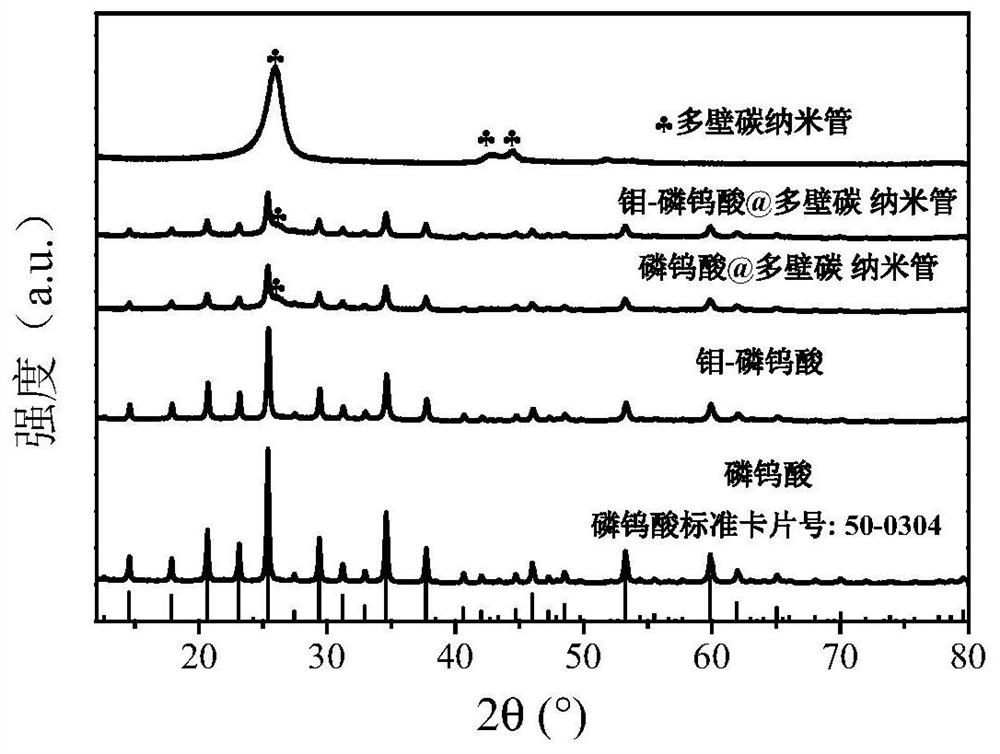

Embodiment 1

[0030] Dissolve 347 μmol of phosphotungstic acid in 10 mL of ethanol solution, add 1.041 μmol of molybdenum pentachloride solution dropwise, stir vigorously for 2 hours under an argon atmosphere, and place the mixed solution in a vacuum rotary evaporator at 100°C The reaction was carried out under heating; the sample was evaporated to dryness and calcined at 200°C for 2h under a hydrogen atmosphere to obtain the sample. Take 50 mg of the obtained sample and dissolve it in 20 mL of ethanol, and add the solution dropwise into a beaker containing 500 mg of multi-walled carbon nanotubes for impregnation reaction at 25° C., with a rotation speed of 1000 r / min and a reaction time of 1 h. After stirring vigorously, place it in an oven at 80°C to dry, so that the sample is encapsulated in multi-walled carbon nanotubes to obtain 0.3% molybdenum-phosphotungstic acid@multi-walled carbon nanotubes.

Embodiment 2

[0032] Dissolve 347 μmol of phosphotungstic acid in 10 mL of ethanol solution, add 1.735 μmol of molybdenum pentachloride solution dropwise, stir vigorously for 2 hours under an argon atmosphere, and place the mixed solution in a vacuum rotary evaporator at 100°C The reaction was carried out under heating; the sample was evaporated to dryness and calcined at 200°C for 2h under a hydrogen atmosphere to obtain the sample. Take 50 mg of the obtained sample and dissolve it in 20 mL of ethanol, and add the solution dropwise into a beaker containing 500 mg of multi-walled carbon nanotubes for impregnation reaction at 25° C., with a rotation speed of 1000 r / min and a reaction time of 1 h. After stirring vigorously, place it in an oven at 80°C to dry, so that the sample is encapsulated in multi-walled carbon nanotubes to obtain 0.5% molybdenum-phosphotungstic acid@multi-walled carbon nanotubes.

Embodiment 3

[0034] Dissolve 347 μmol of phosphotungstic acid in 10 mL of ethanol solution, add 2.429 μmol of molybdenum pentachloride solution dropwise, stir vigorously for 2 hours under an argon atmosphere, and place the mixed solution in a vacuum rotary evaporator at 100°C The reaction was carried out under heating; the sample was evaporated to dryness and calcined at 200°C for 2h under a hydrogen atmosphere to obtain the sample. Take 50 mg of the obtained sample and dissolve it in 20 mL of ethanol, and add the solution dropwise into a beaker containing 500 mg of multi-walled carbon nanotubes for impregnation reaction at 25° C., with a rotation speed of 1000 r / min and a reaction time of 1 h. After stirring vigorously, place it in an oven at 80°C to dry, so that the sample is encapsulated in multi-walled carbon nanotubes to obtain 0.7% molybdenum-phosphotungstic acid@multi-walled carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com