Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of DRAM manufacturing process difficulty, performance needs to be further improved, and DRAM feature size is small, so as to shorten product production cycle, The effect of avoiding adverse effects and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It can be seen from the background art that the manufacturing process of DRAM is becoming more and more difficult, the production cycle is getting longer and longer, and its performance needs to be further improved. After analysis, it is found that the main reason is that the transistors and capacitors of DRAM are usually formed sequentially on one substrate. However, as the size of DRAM continues to shrink, the process difficulty continues to increase and the production time continues to increase.

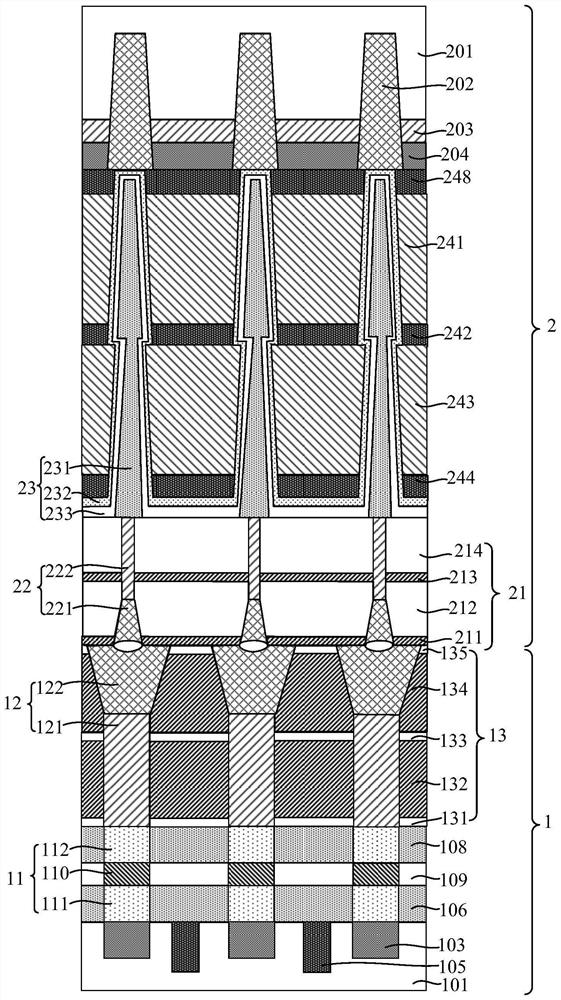

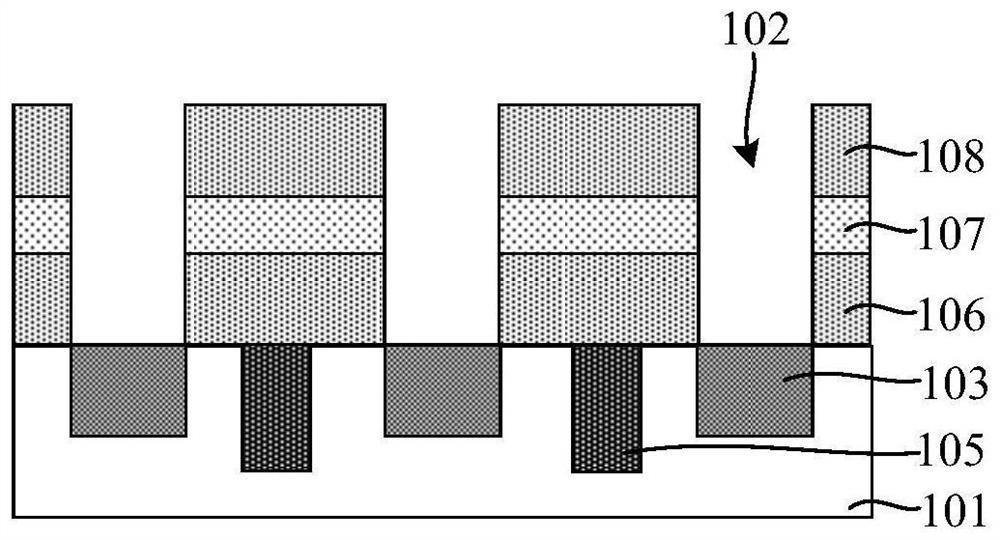

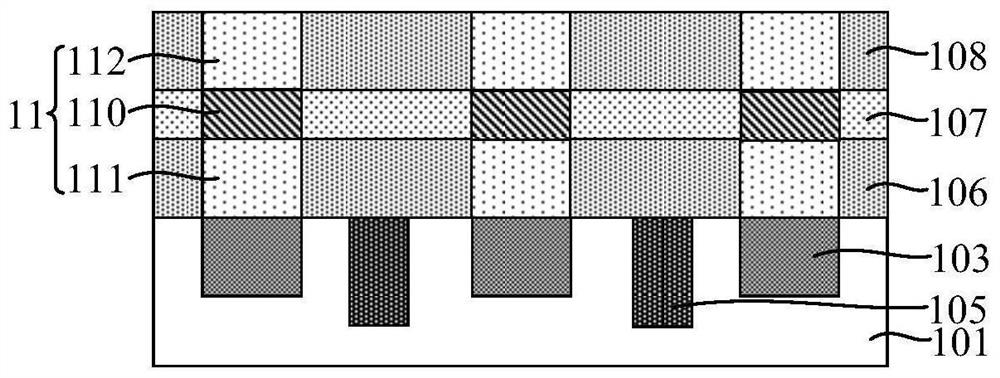

[0034] In order to solve the above problems, an embodiment of the present invention provides a semiconductor structure, the semiconductor structure includes: a first substrate, and a second substrate bonded to the first substrate, and the manufacturing process can be performed on the first substrate and the second substrate On, so can shorten the product production cycle. In addition, the first contact structure has a first surface facing the second substrate and a second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com