Automatic winding and bundling method and device for carrying out method

An automatic winding and equipment technology, applied in the direction of binding materials, parts of binding machinery, paper/cardboard containers, etc. Low efficiency and other problems, to achieve the effect of shortening the product production cycle, saving manpower and material resources, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

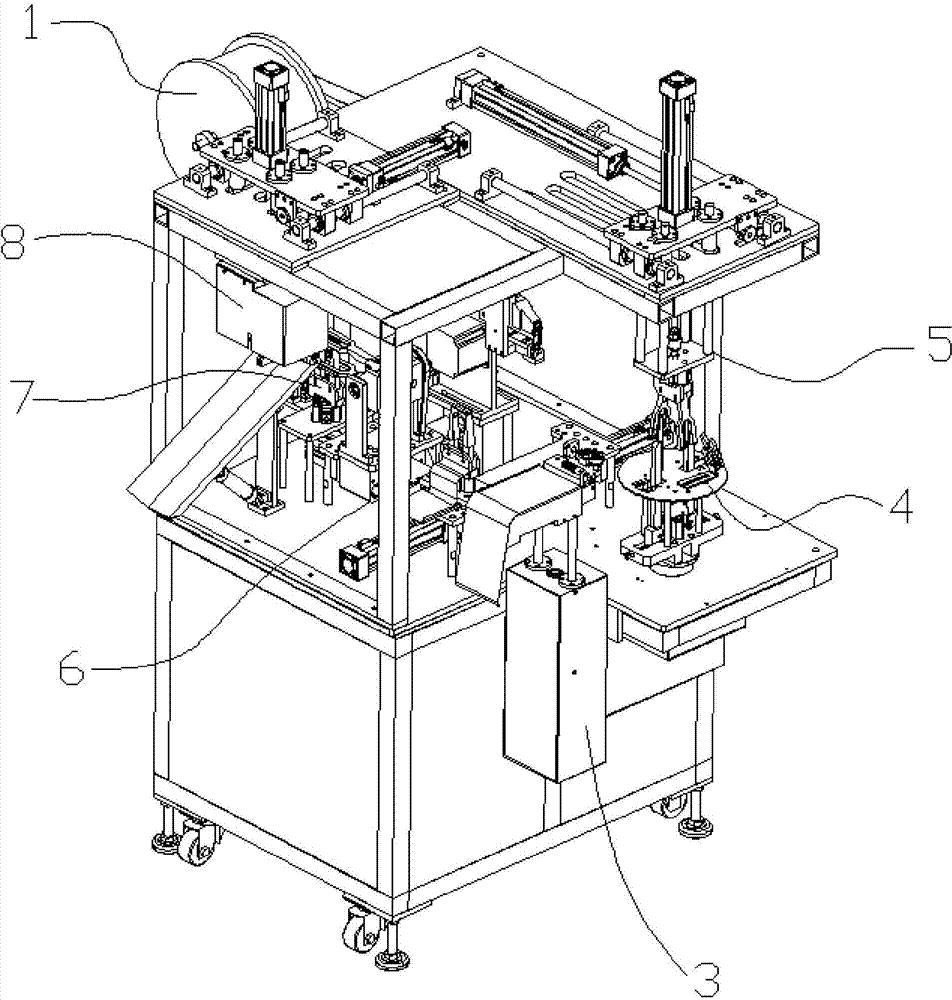

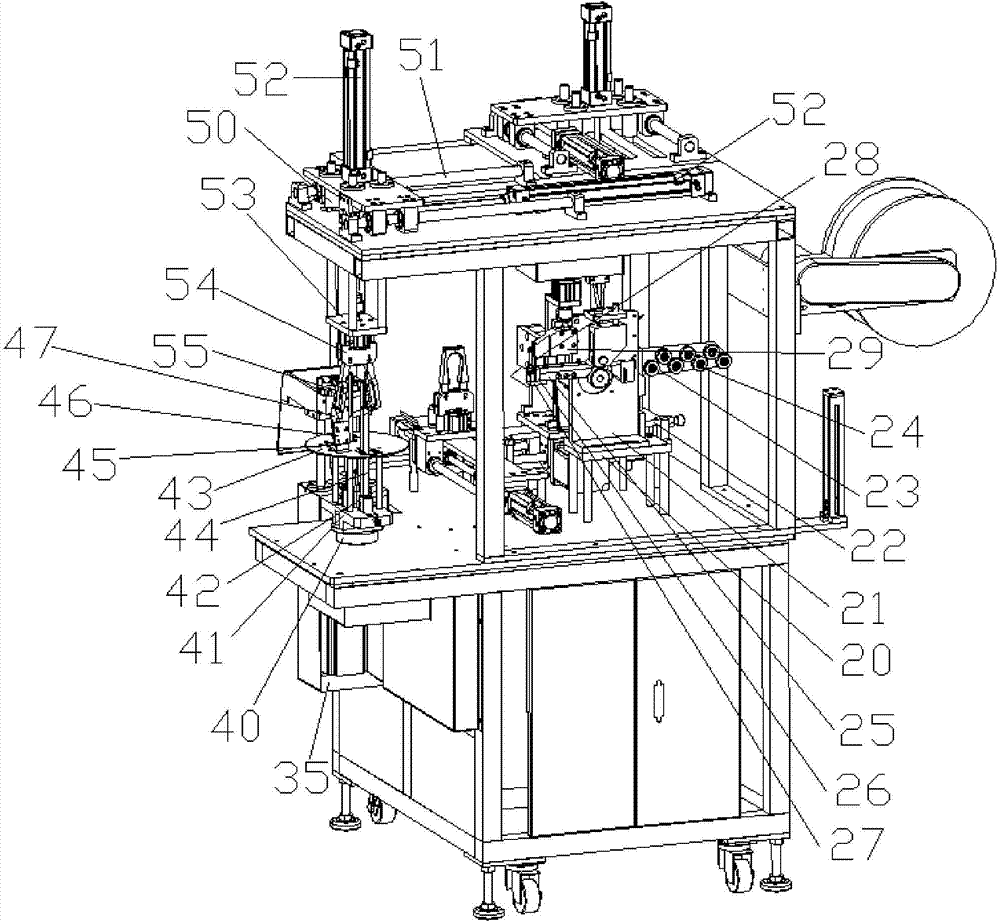

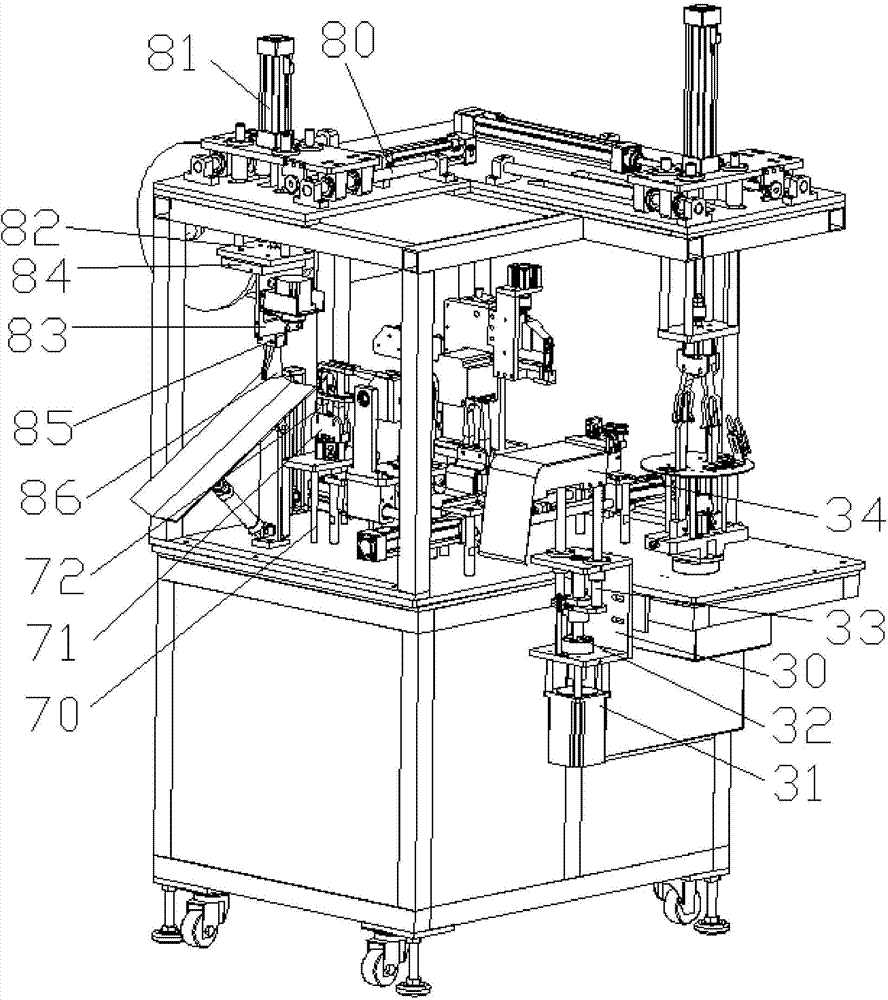

[0038] Embodiment 1: see Figure 1 ~ Figure 4 , the automatic winding and binding method provided by the present embodiment, it comprises the following steps:

[0039] (1) Install cable tie device 1, cable tie sending device 2, wire grab device 3, wire winding device 4, wire arranging device 5, wiring device 6, wire wrapping device 7, and twist tie device 8; set on the main frame;

[0040] (2) PLC control system is set, and this PLC control system is connected with above-mentioned each device respectively, and controls the operation of each device;

[0041] (3) Start the cable tie placing device 1, which is used to automatically supply the cable tie to realize the feeding action;

[0042] (4) Start the cable tie feeding device 2, which is used to cut the cable tie in sections to realize the cutting action, and transfer the cut cable tie to the wire wrapping station;

[0043] (5) Start the cable arrangement device 5, which is used to automatically supply the wire rod to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com