Assembly line scheduling system and method based on PLC and AI identification results

A technology for identifying results and scheduling systems, applied in control/regulation systems, general-purpose control systems, and program control in sequence/logic controllers, etc. It can solve the problem that the manual recognition speed is slow, the solution structure is too complex, and the overall structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

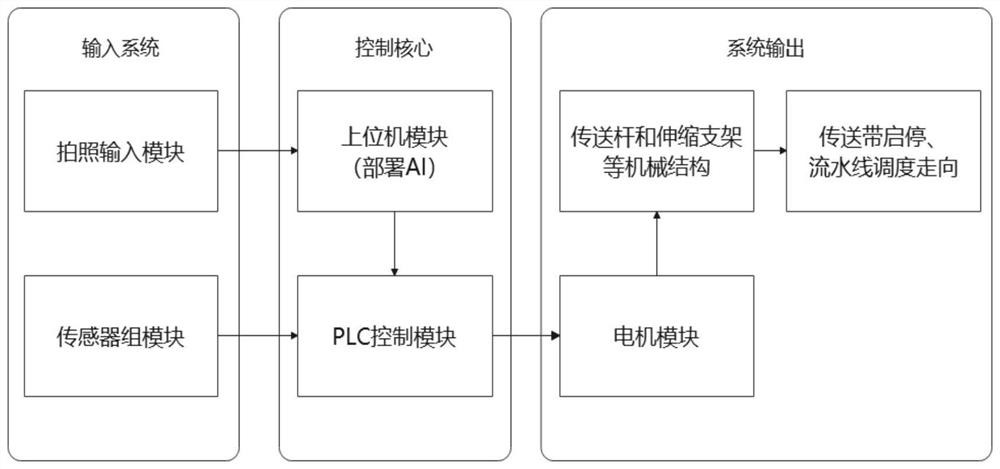

[0059] A pipeline scheduling system based on PLC and AI recognition results, such as figure 1 As shown, including camera input module, sensor group module, PLC control module, host computer module, motor module;

[0060] The photo input module is used to take pictures of the appearance of the product to be detected on the assembly line, and input the photo of the appearance of the product to the upper computer module;

[0061] The AI target detection algorithm is deployed in the upper computer module to detect whether the appearance of the product is qualified, and control the output of the PLC control module according to the detection results;

[0062] The sensor group module is used to detect the position of the product on the assembly line, and input the position of the product on the assembly line to the PLC control module;

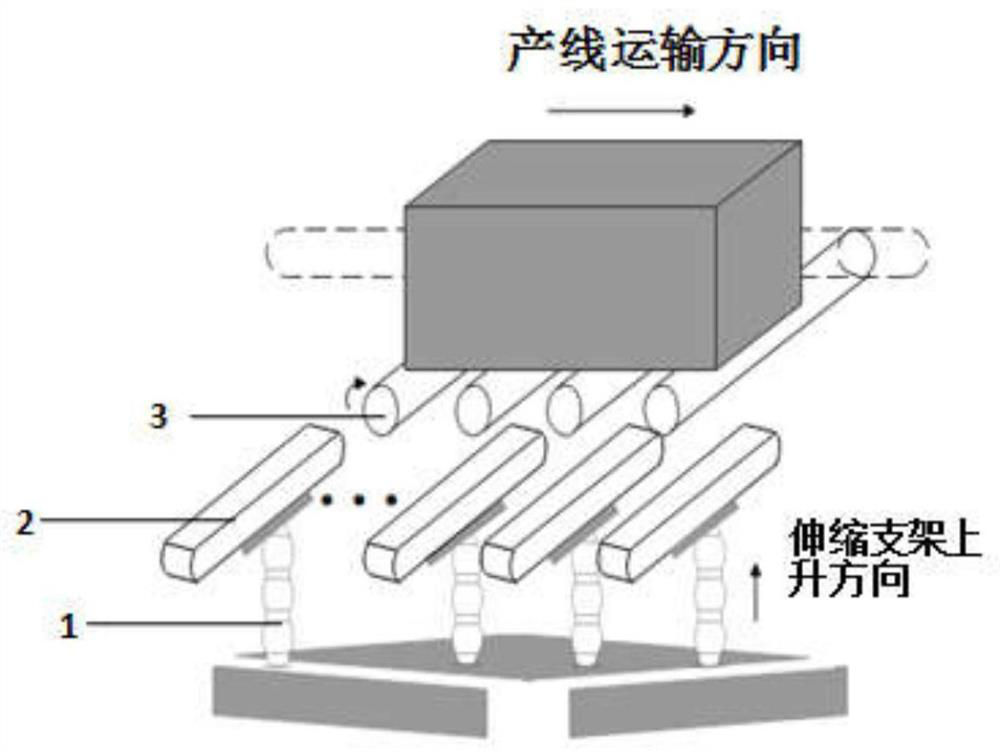

[0063] The PLC control module controls the operation of the motor module based on the detection results of the upper computer module and the posit...

Embodiment 2

[0066] According to the pipeline scheduling system based on PLC and AI recognition results provided in Embodiment 1, the difference is that:

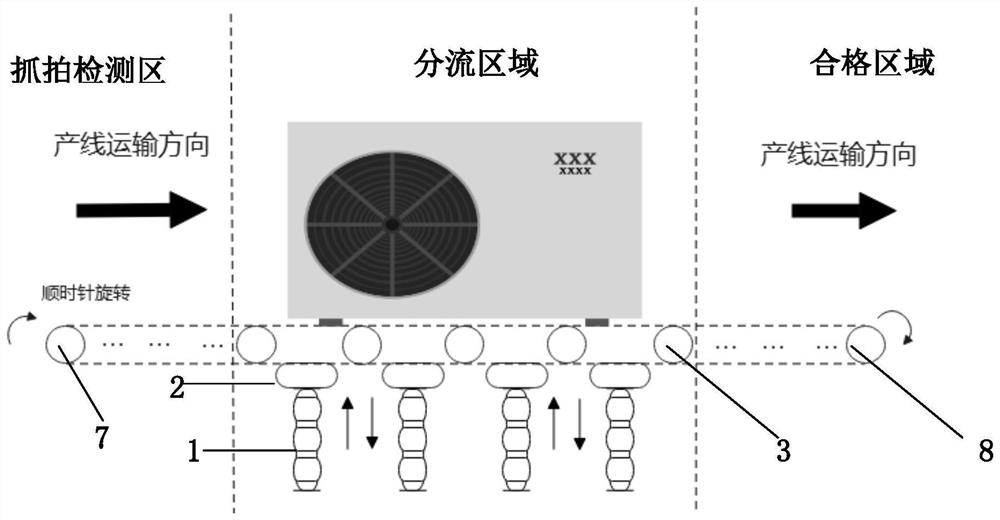

[0067] The assembly line includes a snapshot detection area, diversion area, qualified area and unqualified area; the snapshot detection area, diversion area, and qualified area are connected sequentially along the production line transportation direction; the unqualified area is connected with the diversion area, and the unqualified area is vertical to the production line direction of transport;

[0068] A camera input module is arranged in the capture detection area; in this embodiment, the camera input module adopts an industrial camera;

[0069] The sensor group module includes a first sensor, a second sensor and a third sensor, such as Image 6 As shown, a first sensor is provided at the junction of the snap detection area and the diversion area, and the first sensor is used to detect whether the product has completely left the sn...

Embodiment 3

[0084] A pipeline flow scheduling method based on PLC and AI results, based on the pipeline flow scheduling system provided in embodiment 1 or 2, such as Figure 7 As shown, the specific methods include:

[0085] S1. Start the air conditioner external unit detection pipeline, such as Image 6As shown in , the assembly line transports the air conditioner external unit according to the production line transportation direction. When it is detected that the product enters the snapshot detection area, the camera input module (industrial camera on the assembly line) captures the appearance photo of the product (air conditioner external unit) and sends the captured The photos are uploaded to the host computer module; the host computer module is a computer that deploys the trained AI target detection algorithm;

[0086] S2. Deploy the trained AI target detection algorithm in the host computer module. The trained AI target detection algorithm detects and recognizes the photos of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com