Non-contact detection device and method for building outer wall surface layer quality

A non-contact, detection device technology, used in measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of difficult detection, low detection efficiency, and inaccurate data, to ensure stability, improve Efficiency and accuracy, the effect of increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

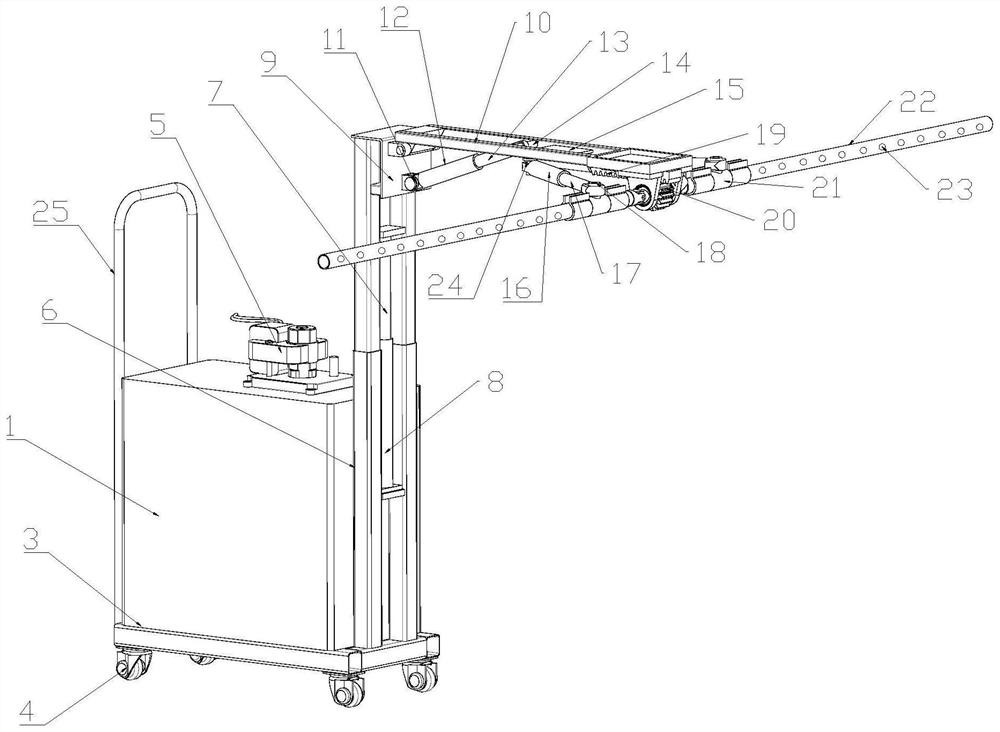

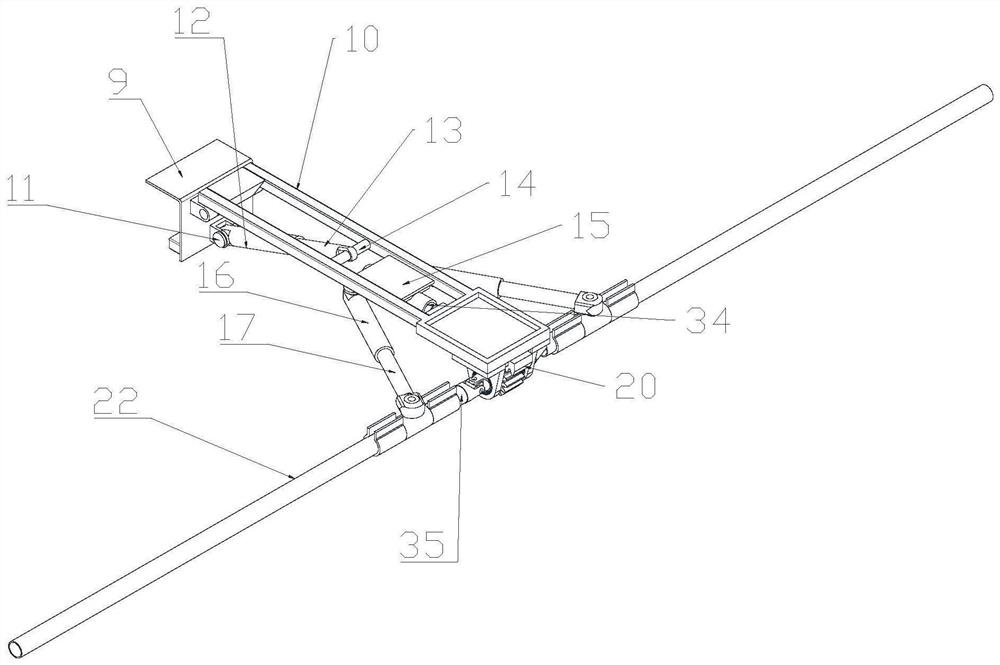

[0037] see Figure 1~4 , in an embodiment of the present invention, a non-contact detection device for the quality of the exterior wall surface layer of a building includes a base 3 and a box body 1 installed on the upper end of the base 3, the upper end of the box body 1 is provided with a handle 2, and the base 3 The lower end of the lower end is provided with several universal wheels 4, and one side of the box body 1 is provided with a first installation frame 6, and one side of the first installation frame 6 is provided with a first hydraulic cylinder 8, and the first hydraulic cylinder 8 The upper end of the cylinder 8 is provided with a first hydraulic rod 7, and a sliding seat 9 is installed on the first hydraulic rod 7. One side of the sliding seat 9 is provided with a second mounting frame 10, and one of the second mounting frame 10 A fixed shaft sleeve 21 is arranged on the side, and a test tube 22 is provided at both ends of the fixed shaft sleeve 21. The side of th...

Embodiment 2

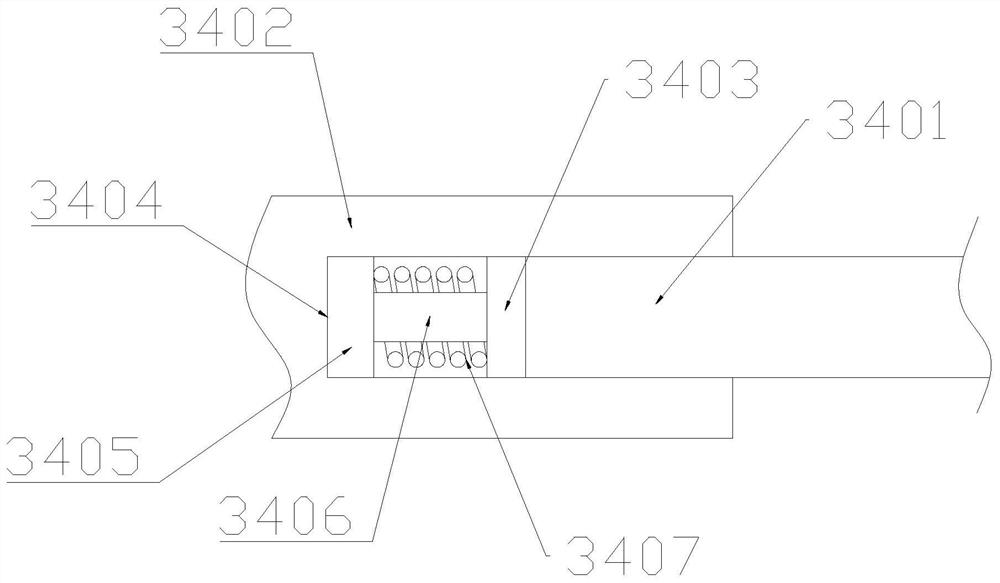

[0048] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the lower end of the second mounting frame 10 is provided with a mounting plate 26, and one side of the mounting plate 26 is provided with several fifth rotating shafts 31. The outer periphery of the fifth rotating shaft 31 is provided with a roller shaft 32 , and the outer periphery of the roller shaft 32 is provided with a buffer bushing 33 . By setting the mounting plate 26 at the lower end of the fifth mounting bracket, several fifth rotating shafts 31 are arranged on one side of the mounting plate 26, the outer periphery of the fifth rotating shaft 31 is provided with a roller shaft 32, and the outer periphery of the roller shaft 32 is provided with a buffer sleeve 33, and the roller shaft 32 rotates around the fifth rotating shaft 31, and the setting of the buffer sleeve 33 can ensure the stability of the movement of the test tube 22, thereby effectively ensuring the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com