Formaldehyde self-absorption type foam glass insulation board

A foam glass and thermal insulation board technology, applied in thermal insulation, building components, sound insulation and other directions, can solve problems such as poor waterproofness, poor sound insulation effect, and difficulty in guaranteeing service life, and achieve the effect of enhancing sound insulation effect and preventing erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

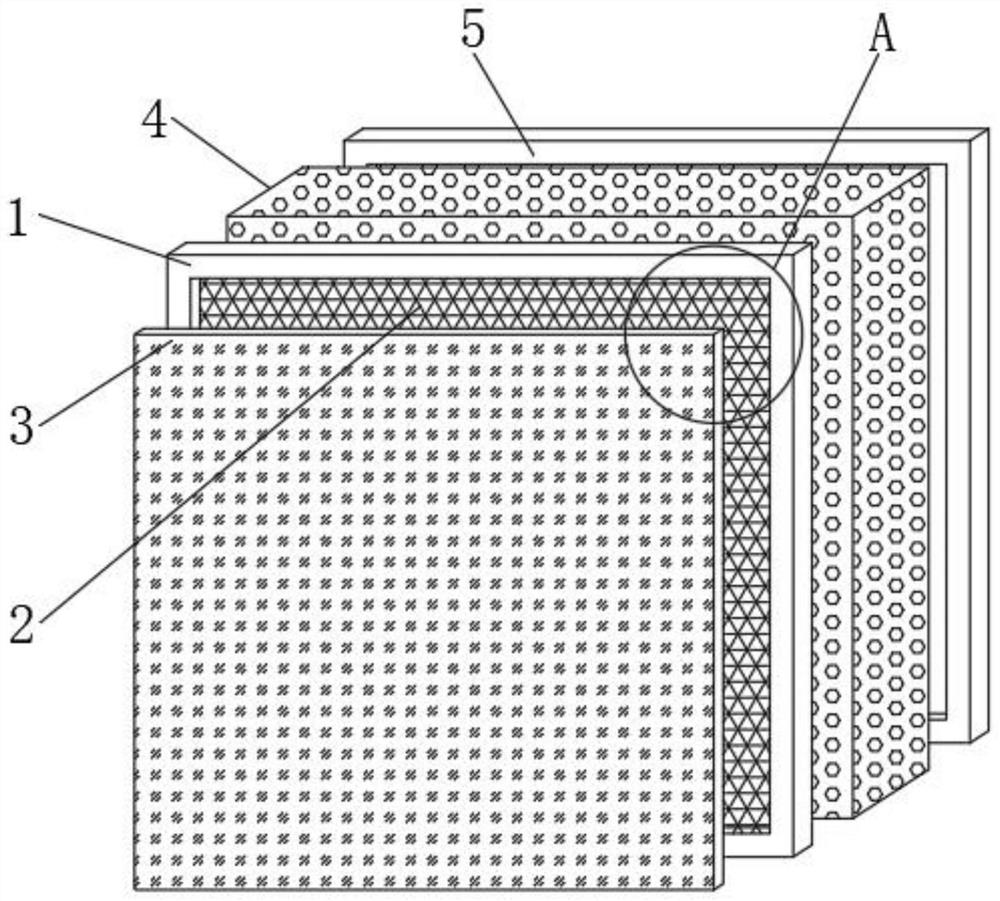

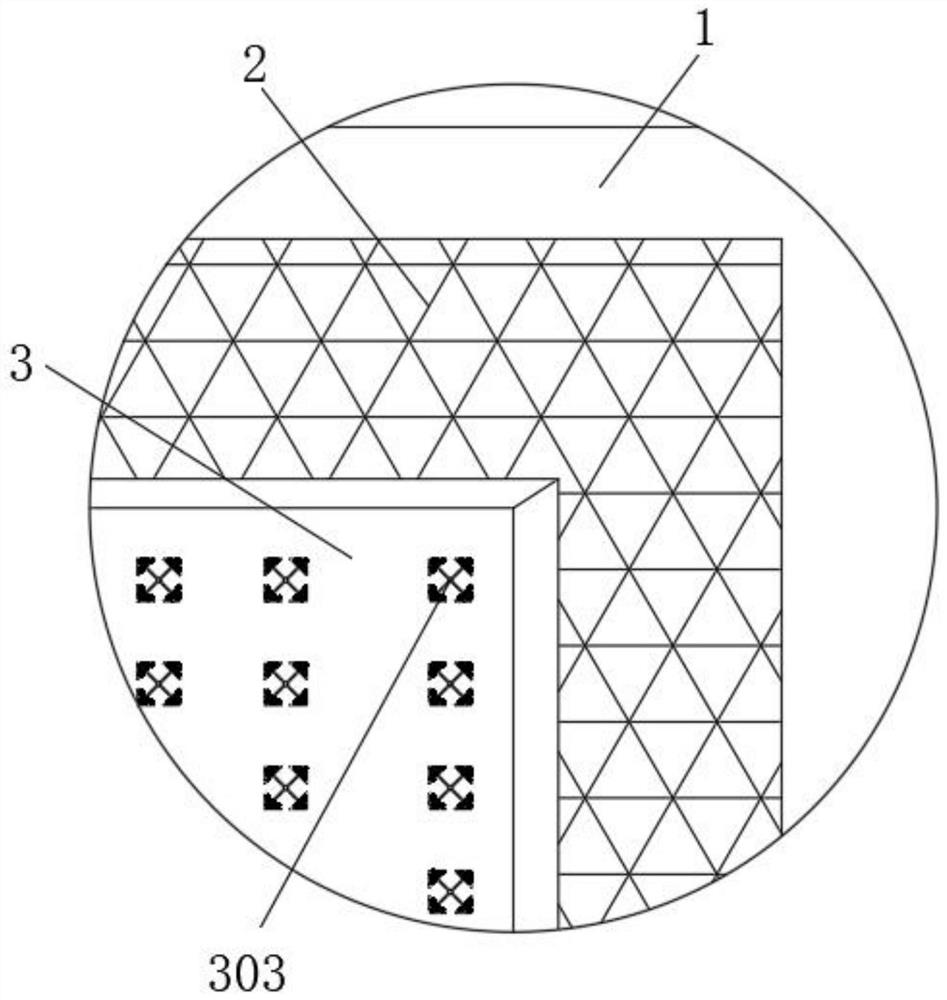

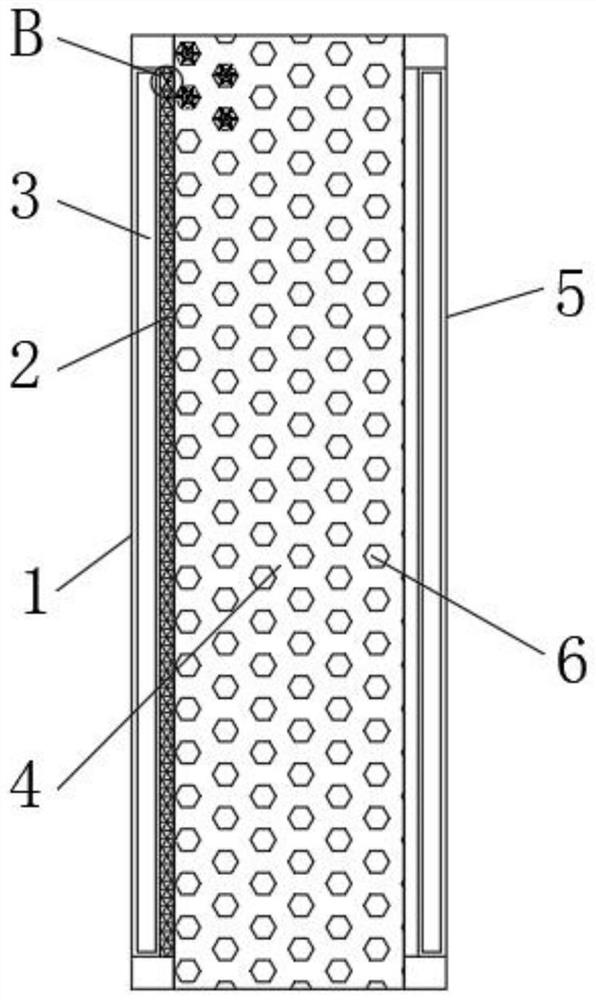

[0041] see Figure 1-8 , a self-priming formaldehyde-type foam glass insulation board, including a first composite sound-absorbing board 1, the inside of the first composite sound-absorbing board 1 is fixedly installed with a drying net 2, and the front side of the drying net 2 is fixedly connected with a sound-absorbing panel 3, the first The rear side of the composite sound-absorbing board 1 is connected with a foam glass insulation board body 4, and the rear side of the foam glass insulation board body 4 is fixedly connected with a second composite noise-absorbing board 5, and the inside of the foam glass insulation board body 4 is provided with a heat-insulating hole 6 for heat preservation. The inside of the hole 6 is fixedly installed with an adsorption ball 7, the outer end of the adsorption ball 7 is fixedly connected with an adsorption fiber 8, the middle and outer side of the adsorption fiber 8 is connected with a positioning purification ball 9, and the outer end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com