Wastewater treatment method

A treatment method and wastewater technology, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of inability to obtain biogas and low COD removal rate, and achieve good degradation and removal effect. Enhanced catabolic metabolism, highly effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

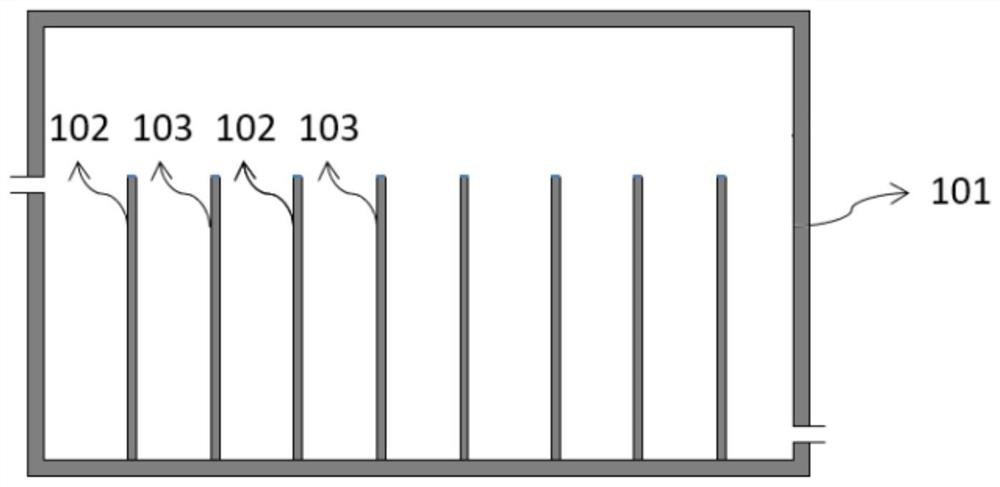

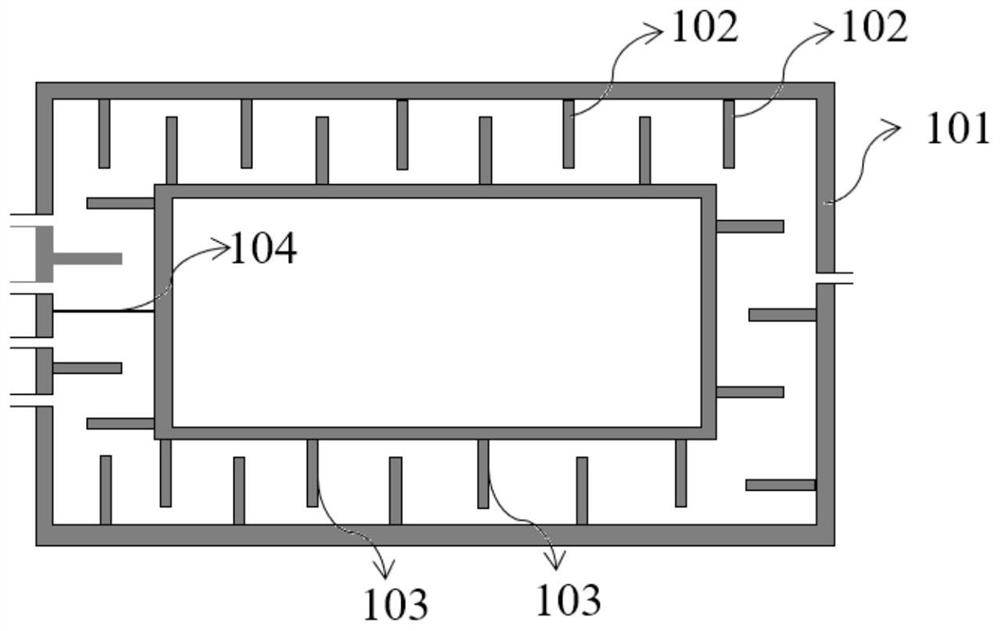

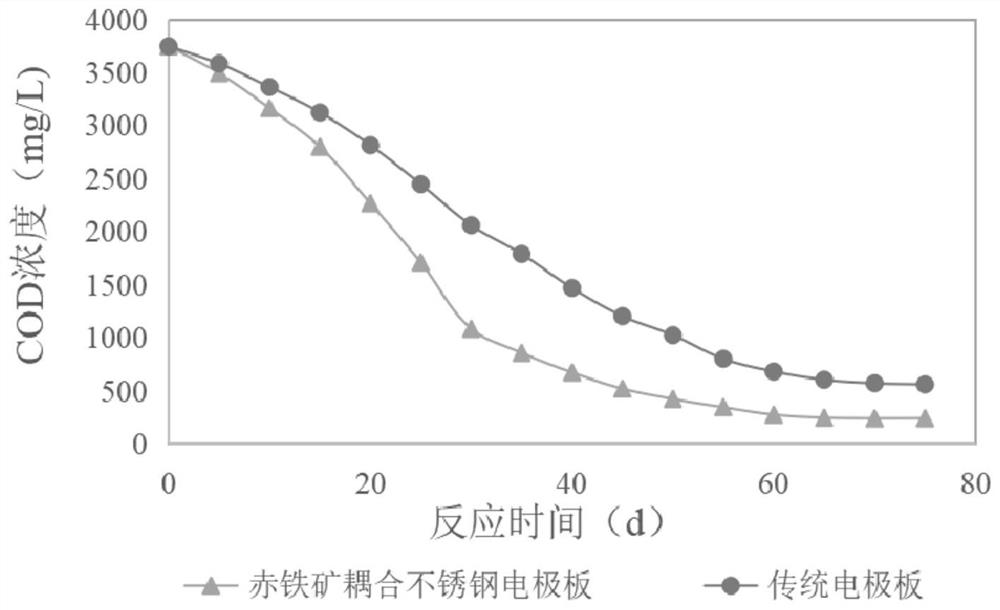

[0047] The food thawing waste water (COD is 3700mg / L) inoculated with 20wt% anaerobic sludge is introduced in the electrolytic cell from the water inlet and carried out electrolytic treatment, such as figure 1 and figure 2 As shown, the electrolytic cell includes a cell body 101 and an anode plate 102 and a cathode plate 103 that are fixed at the inner bottom of the cell body 101 and are respectively fixed on two opposite inner sidewalls of the cell body 101, the anode plate 102 and the cathode plate 103 The number of cathode plates 103 is multiple and a plurality of anode plates 102 and cathode plates 103 are arranged alternately along the water flow direction to form a baffle channel, and the anode plate 102 is a stainless steel plate ( Hematite coupling stainless steel electrode plate), the conductive layer is a composite layer formed by hematite, magnetite and activated carbon according to the mass ratio of 1.5:0.5:1. The cathode plate 103 is a stainless steel plate. Th...

Embodiment 2

[0055] The food thawing waste water (COD is 3800mg / L) inoculated with 20wt% anaerobic sludge is introduced in the electrolytic cell from the water inlet and carried out electrolytic treatment, such as figure 1 and figure 2 As shown, the electrolytic cell includes a cell body 101 and an anode plate 102 and a cathode plate 103 that are fixed at the inner bottom of the cell body 101 and are respectively fixed on two opposite inner sidewalls of the cell body 101, the anode plate 102 and the cathode plate 103 The number of cathode plates 103 is multiple and a plurality of anode plates 102 and cathode plates 103 are arranged alternately along the water flow direction to form a baffle channel. The anode plate 102 is a stainless steel plate with a thickness of 10 μm conductive layer on the surface, The conductive layer is a composite layer formed of hematite, magnetite and activated carbon in a mass ratio of 3:2:1. The electrolytic cell has a hollow structure that penetrates up and ...

Embodiment 3

[0057] The food thawing waste water (COD is 3750mg / L) inoculated with 20wt% anaerobic sludge is introduced in the electrolytic cell from the water inlet and carried out electrolytic treatment, such as figure 1 and figure 2 As shown, the electrolytic cell includes a cell body 101 and an anode plate 102 and a cathode plate 103 that are fixed at the inner bottom of the cell body 101 and are respectively fixed on two opposite inner sidewalls of the cell body 101, the anode plate 102 and the cathode plate 103 The number of cathode plates 103 is multiple and a plurality of anode plates 102 and cathode plates 103 are arranged alternately along the water flow direction to form a baffle channel. The anode plate 102 is a stainless steel plate with a thickness of 7 μm conductive layer on the surface, The conductive layer is a composite layer formed of hematite, magnetite and activated carbon in a mass ratio of 2:1:1. The electrolytic cell has a hollow structure that penetrates up and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com