Process for recycling ammonia-containing wastewater of drainage tank of thermal power plant unit

A technology for drainage tanks and thermal power plants, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as difficult treatment, reduce acid-base wastewater, reduce acid The amount of alkaline wastewater and the effect of avoiding ammonia volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

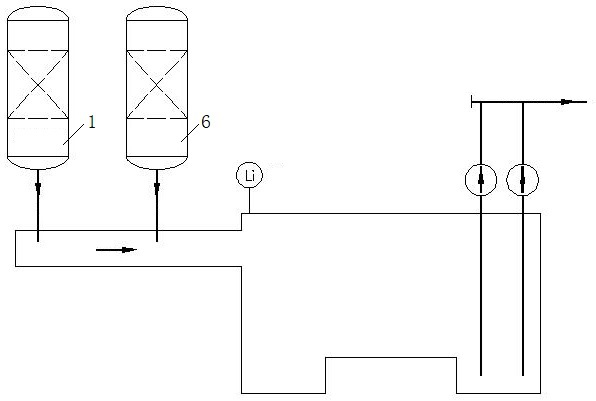

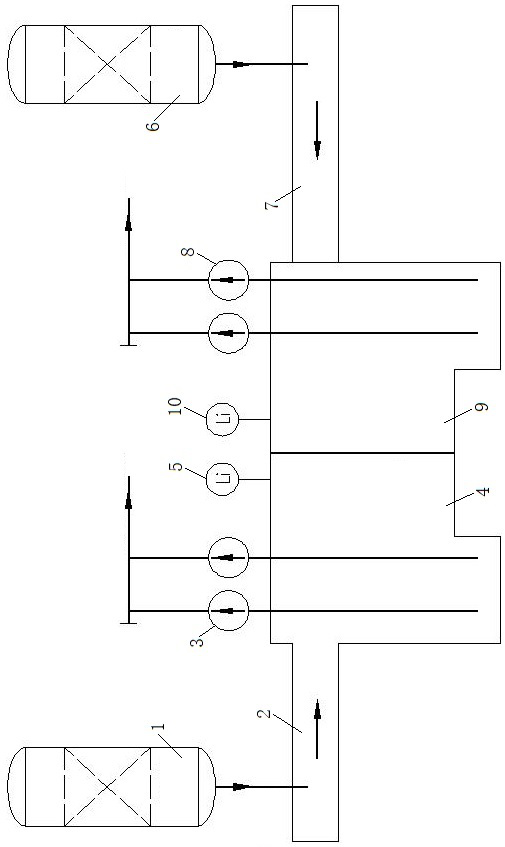

[0015] see figure 2 , in this embodiment, a process for recycling ammonia-containing wastewater in the drainage tank of a thermal power plant unit, the system includes a cation resin recovery tank 1, an acidic wastewater drainage ditch 2, an acidic wastewater delivery pump 3, an acidic wastewater collection pool 4, and an acidic wastewater level Meter 5, anion resin recovery tank 6, alkaline waste water drainage ditch 7, alkaline waste water delivery pump 8, alkaline waste water collection tank 9 and alkaline waste water level gauge 10; the outlet of positive resin recovery tank 1 is connected to acid waste water Drainage ditch 2, acid waste water drainage ditch 2 is connected to acid waste water collection pool 4, acid waste water collection pool 4 is connected to industrial waste water pool through acid waste water delivery pump 3, and acid waste water level gauge 5 is installed in acid waste water collection pool 4; The outlet of the resin recovery tank 6 is connected to t...

Embodiment 2

[0020] In a power plant in Hubei, the regenerated wastewater of the condensate polishing system is 3.6t / h, and the regenerated wastewater is directly discharged to the drainage tank of the unit. There is a large ammonia smell near the unit drainage tank for a long time, which has a great impact on the on-site operation and maintenance staff . At present, the power plant reuses this part of wastewater to the wet residue system, fuel system, dry ash mixing, etc. However, when it rains in summer, it is difficult to reuse this part of the wastewater, which affects environmental safety.

[0021] After the technical transformation of the present invention, the drainage tank of the unit is divided into an acidic wastewater pool and an alkaline wastewater pool, and a new alkaline wastewater drainage ditch is built to collect the alkaline wastewater separately and reuse it in the desulfurization system. After the transformation, the ammonia odor in the drainage tank of the unit was sig...

Embodiment 3

[0023] In a power plant in Heilongjiang, the regenerated wastewater of the condensate polishing system is 2t / h, and the regenerated wastewater is directly discharged to the unit drainage tank. There is a long-term ammonia smell near the unit drainage tank, which has a great impact on the on-site operation and maintenance staff. At present, the power plant reuses this part of wastewater to the fuel system, dry ash mixing, etc. With the closure of the coal yard, the fuel system cannot absorb so much acid-base wastewater, which has a great impact on environmental safety.

[0024] After the technical transformation of the present invention, the drainage tank of the unit is divided into an acidic wastewater pool and an alkaline wastewater pool, and a new alkaline wastewater drainage ditch is built to collect the alkaline wastewater separately and reuse it in the desulfurization system. After the transformation, the ammonia odor in the drainage tank of the unit was significantly redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com