Traditional Chinese medicine continuous dry granulation system and granulation method

A dry granulator, a technology for traditional Chinese medicine granules, applied in chemical instruments and methods, methods for granulating raw materials, mixing methods, etc., can solve problems such as low granulation efficiency, improve production efficiency, ensure qualified quality, reduce The effect of transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

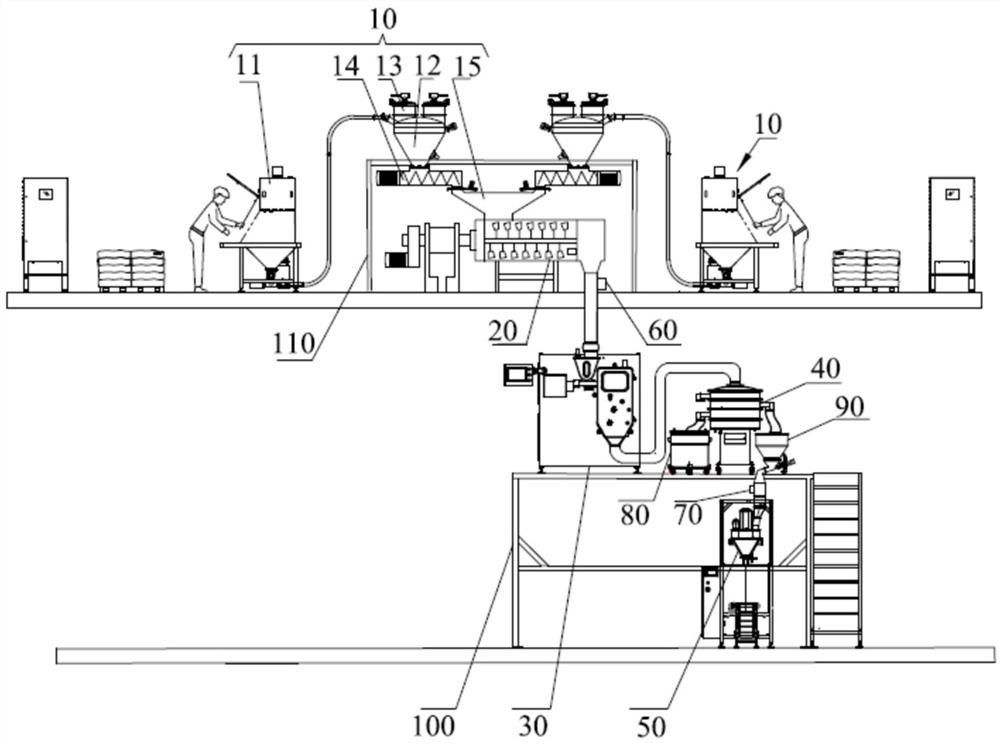

[0041] see Figure 1 to Figure 3 , shows the continuous dry granulation system for traditional Chinese medicine in the first embodiment of the present invention, including a feed assembly 10, a material mixing device 20, a dry granulator 30, a particle screening device 40, a particle packaging device 50, a material Uniformity inspection device 60 and particle parameter inspection device 70 . in:

[0042] The feeding assembly 10 includes a dust-free feeding station 11, a first temporary storage bin 12, a vacuum feeder 13 and an automatic feeder 14. The dust-free feeding station 11 is connected to the first temporary storage bin 12 through a pipeline, and the vacuum feeder 13 is connected to the first temporary storage bin 12, which is used to suck the materials input from the dust-free feeding station 11 into the first temporary storage bin 12, and the feeding port of the automatic feeder 14 is connected to the output of the first temporary storage bin 12 The outlet of the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com