Lead frame for diode forming, diode and manufacturing method of diode

A lead frame and diode technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of many processes, increase the number of lead frames, and high costs, reduce glue overflow gaps, and improve molding efficiency. The effect of good cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

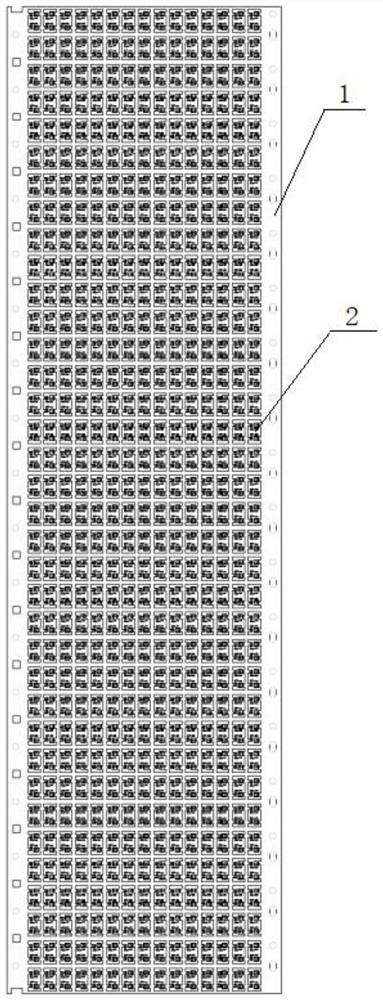

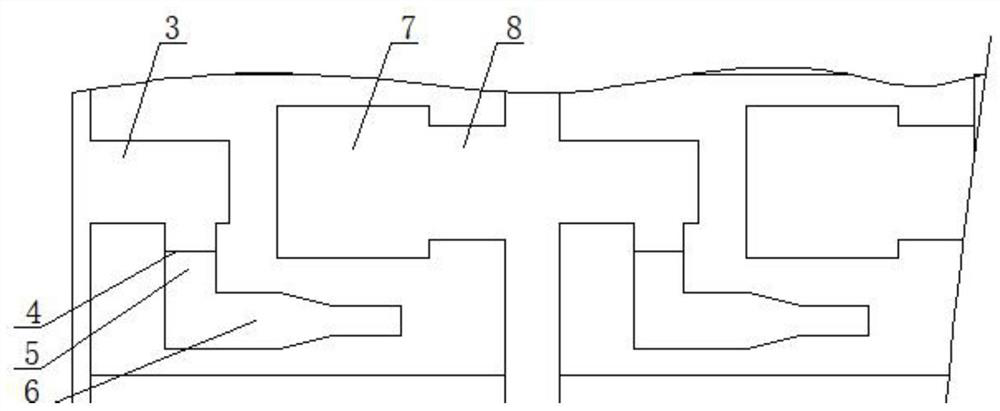

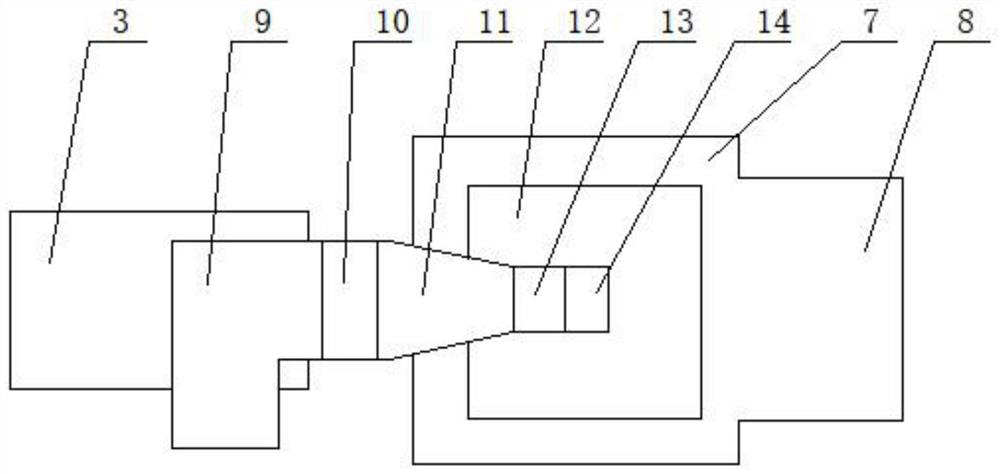

[0040] A lead frame for diode molding, including a profile 1, the innovation of which is that several diode frame units 2 are evenly spaced on the profile, and one or two diode frame units are arranged on each of the diode frame units. Diode molding bodies, such as figure 2As shown, a diode forming body is arranged in the diode frame, and each of the diode forming bodies is composed of a first pin 3, a second pin 8, a chip support piece 7 and a lead pole piece. The left and right sides of the frame of the diode frame unit are relatively provided with a first pin and a second pin integrated with the profile, and an L-shaped lead pole piece is integrally formed on the lower side of the first pin to the right. The L-shaped lead pole piece is composed of a connecting piece part 5 arranged perpendicularly to the first pin and a lead pole piece part 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com