An optimal control system and method for steam inlet throttling of steam turbines to meet peak shaving requirements

A control method and steam turbine technology, applied to steam engine devices, mechanical equipment, engine components, etc., can solve problems such as single available technology, unsatisfactory peak shaving depth, and reduced profitability of coal-fired power units, so as to achieve low investment and small transformation scope Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

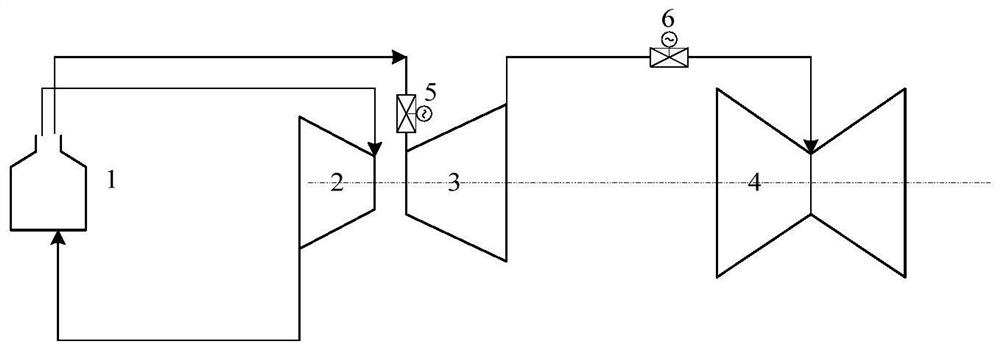

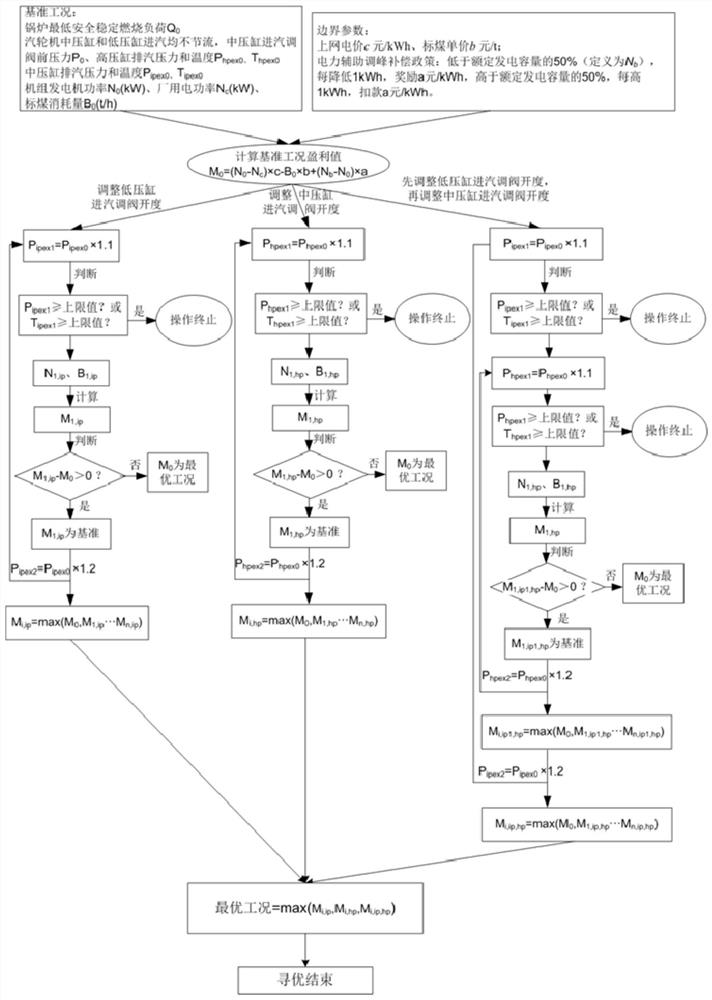

[0069] Taking a 300MW steam turbine generator set as an example, the embodiments of the present invention will be described in detail.

[0070] Step 1: Basic data preparation

[0071] 1) Steam turbine

[0072] For a 300MW subcritical, primary reheat, condensing steam turbine generator set, the maximum continuous evaporation of the boiler is 1060t / h, and the minimum safe and stable combustion load is 424t / h (40% of the maximum continuous evaporation).

[0073] The safe operation upper limit of the exhaust steam pressure of the high-pressure cylinder is 3.7MPa, and the safe operation upper limit of the exhaust steam temperature of the high-pressure cylinder is 380℃.

[0074] The safe operation upper limit of the exhaust steam pressure of the medium pressure cylinder is 0.9MPa, and the safe operation upper limit of the exhaust steam temperature of the medium pressure cylinder is 390℃.

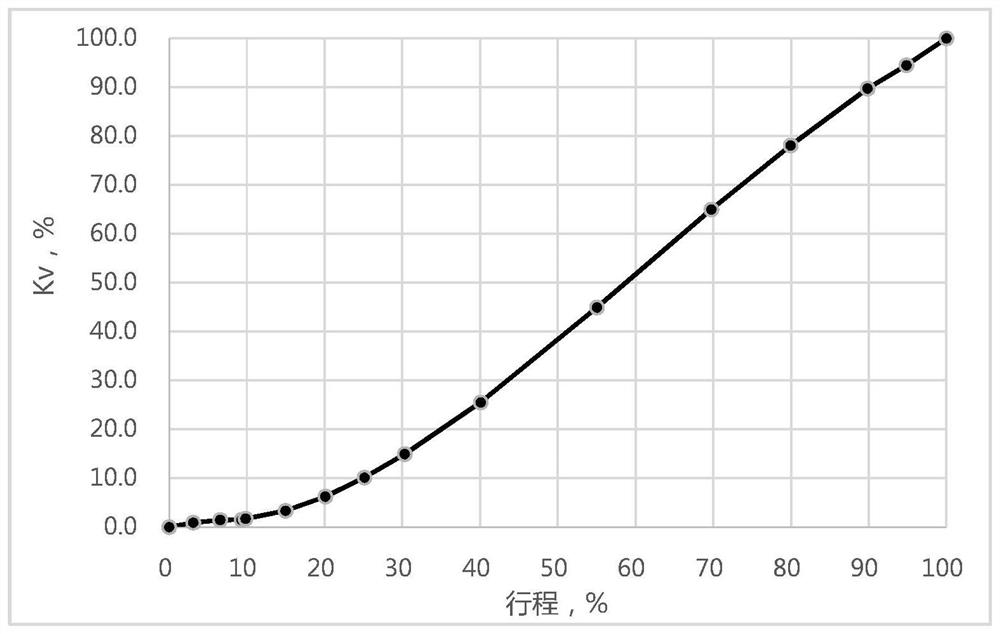

[0075] 2) Inlet steam regulating valve of medium pressure cylinder, steam inlet regulating v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com