Low-melting-point salt and water combined energy level utilizing system for peak shaving of thermal unit

A technology of thermal power units and low melting point, which is applied in the field of molten salt energy storage transformation and urban hot water supply system, which can solve the problems of high energy storage cost, low heat grade, and influence of saturation temperature, and achieve the effect of reducing energy storage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

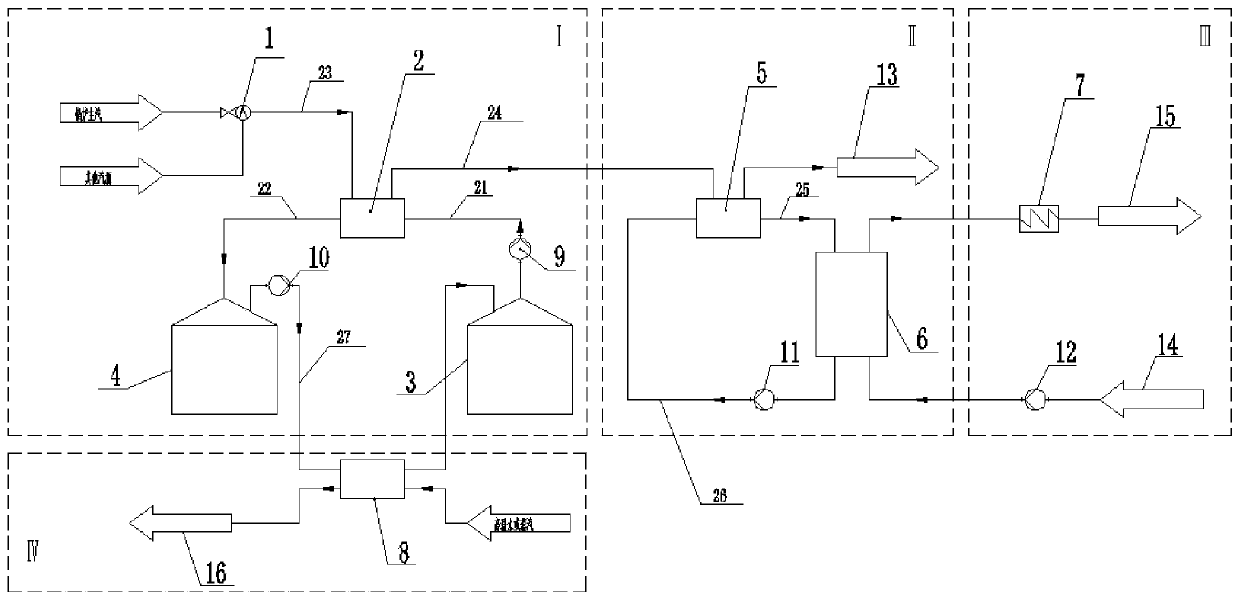

[0012] Specific implementation mode 1: The low-melting-point salt and water combined energy-level utilization system for peak regulation of thermal power units in this embodiment includes low-melting-point salt energy storage system I, water energy storage system II, hot water supply system III, and high-temperature molten salt heat exchange system Ⅳ, wherein the low-melting point salt energy storage system Ⅰ includes temperature and pressure regulator 1, brine heat exchanger 2, cold brine tank 3 and hot brine tank 4, and the outlet of cold brine tank 3 is exchanged with brine through No. 1 salt delivery pipe 21 The inlet of the heat exchanger 2 is connected, the outlet of the brine heat exchanger 2 is connected with the inlet of the hot brine tank 4 through the No. The No. 1 connecting pipe 23 is provided with a temperature and pressure regulator 1;

[0013] The water energy storage system II includes a water-water heat exchanger 5 and a hot water storage tank 6. The medium o...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that a cold salt pump 9 is provided in the No. 1 salt delivery pipe 21 .

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that a hot salt pump 10 is provided in the No. 3 salt delivery pipe 27 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com