Heat supply system

A heating system and heating device technology, applied in heating systems, hot water central heating systems, heating fuels, etc., can solve problems such as unfavorable thermal power unit renovation plans, large renovation scope, and complicated process, and achieve energy improvement Utilization rate, reduction of transformation scope, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

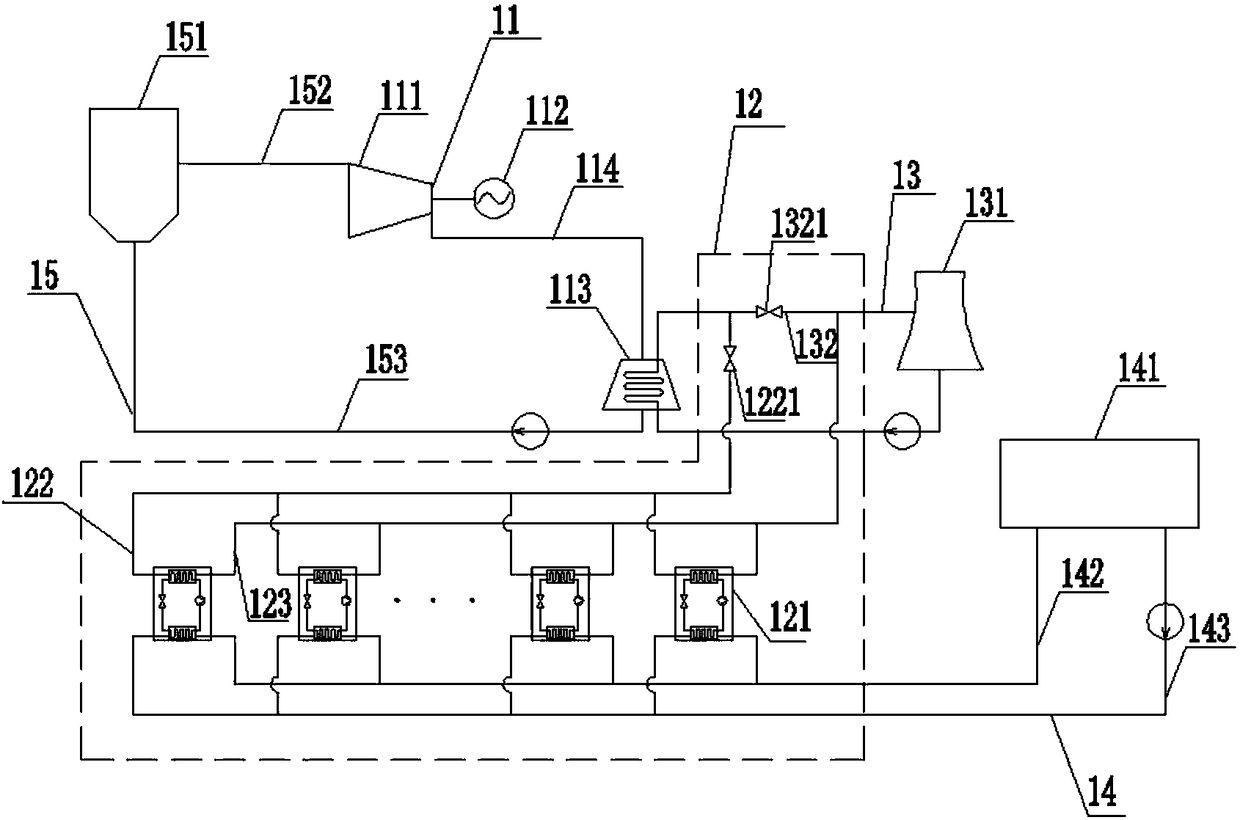

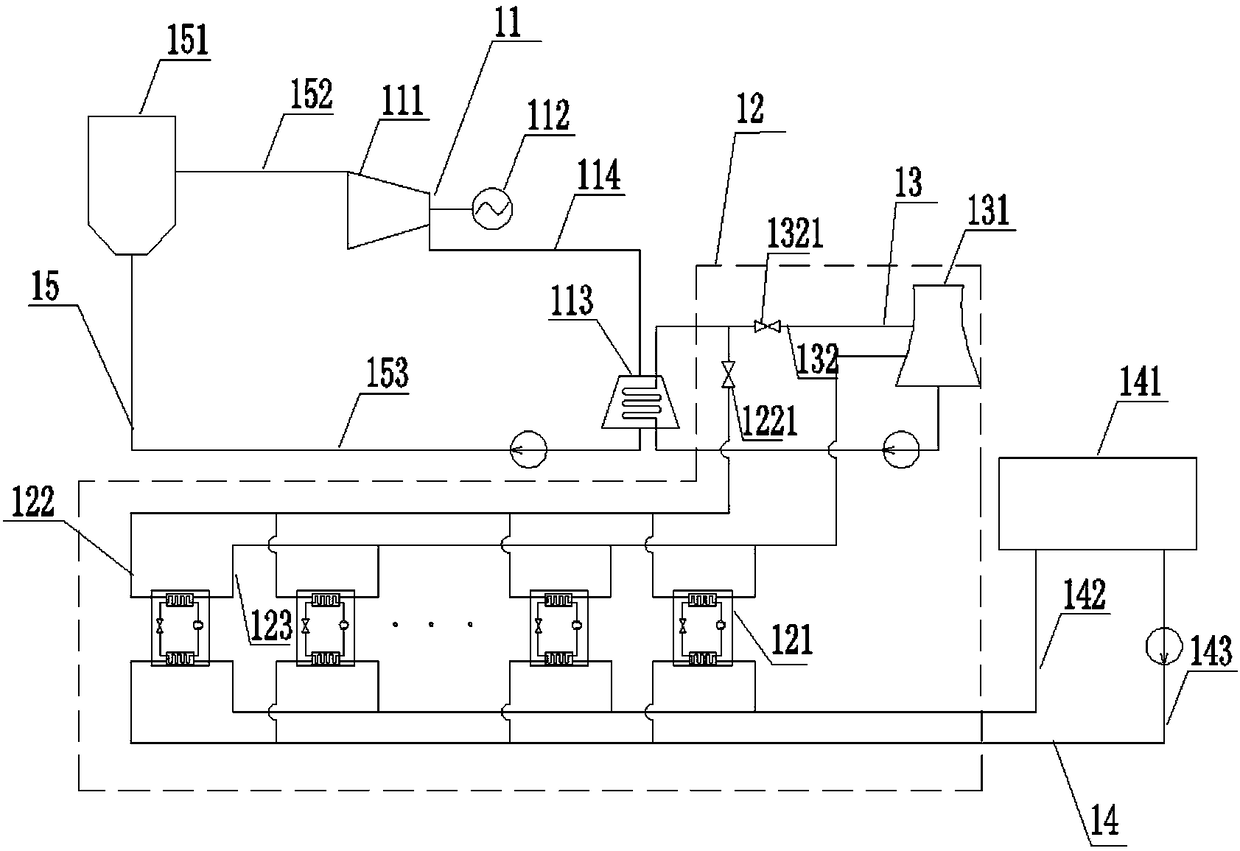

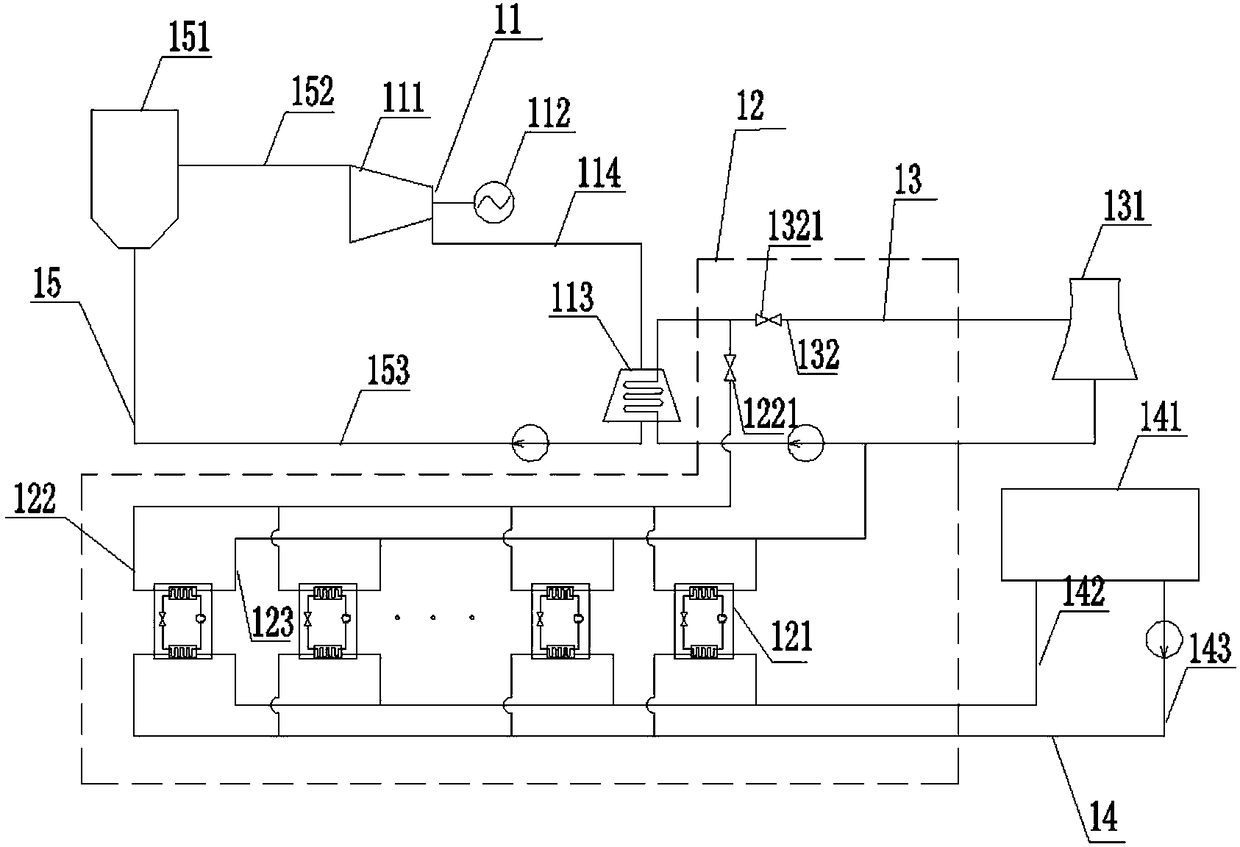

[0020] figure 1 It is the first structural schematic diagram of the heating system in Embodiment 1 of the present invention. Such as figure 1 As shown, the system includes: a steam turbine unit (11), a heat pump device (12), a circulating water device (13) and a heating device (14);

[0021] The steam turbine unit (11) is connected to the circulating water device (13), and the circulating water device (13) absorbs heat from the steam turbine unit (11);

[0022] The heat pump device (12) is connected to the circulating water device (13), and the heat pump device (12) absorbs heat in the circulating water device (13);

[0023] The heat supply device (14) is connected with the heat pump device (12), and the heat pump device (12) transfers the heat absorbed from the circulating water device (13) to the heat supply device (14) for heat supply.

[0024] In the embodiment of the present invention, the steam turbine unit (11) refers to a rotary power machinery unit that converts st...

Embodiment 2

[0060] Figure 5 It is a schematic diagram of the first connection mode of the heat pump device in the heating system in the second embodiment of the present invention. When the heat user needs a higher heating temperature, the connection mode of the heat pump device (12) can be adjusted, such as Figure 5 As shown, multiple heat pumps can also be connected in parallel and then in series. The heating return water with a temperature of T21 from the heating return pipe (143) enters the first group of heat pumps through multiple branch pipes, and the temperature rises to T21' under the action of the first group of heat pumps, and the temperature in each branch pipe is T21' After the heating and returning water are merged, they enter the second group of heat pumps, continue to absorb the heat of the circulating water under the action of the second group of heat pumps and rise to T22, and then merge to the heating water supply pipe (142) for heating.

[0061] Image 6 It is a sc...

Embodiment 3

[0067] Figure 7 It is a structural schematic diagram of the heating system in Embodiment 3 of the present invention. Such as Figure 7 As shown, on the basis of the foregoing embodiments, the system also includes: a steam turbine extraction device (16), wherein the steam turbine extraction device (16) includes: a steam turbine extraction pipeline (161), a steam heater drain pipeline (162) and steam heater (163);

[0068] The steam turbine extraction device (16) is connected to the steam turbine unit (11); wherein, the steam turbine extraction device (16) extracts the steam in the steam turbine (111);

[0069] The steam heater (163) is arranged on the heating water supply pipe (142); wherein, the steam heater (163) uses steam to heat the heating water supply to supply heat to the heating equipment (141).

[0070] In the embodiment of the present invention, the steam turbine extraction device (16) refers to a device for extracting part of the steam from the steam turbine (11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com