Efficient processing technology for clothes

A kind of processing technology and high-efficiency technology, applied in textile processing machine accessories, textile and papermaking, textile material processing and other directions, can solve the problems of mottled fabrics, uneven hydrophilic finishing of fabrics, etc., to improve the quality and shorten the hydrophilic finishing. time, the effect of reducing loads and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

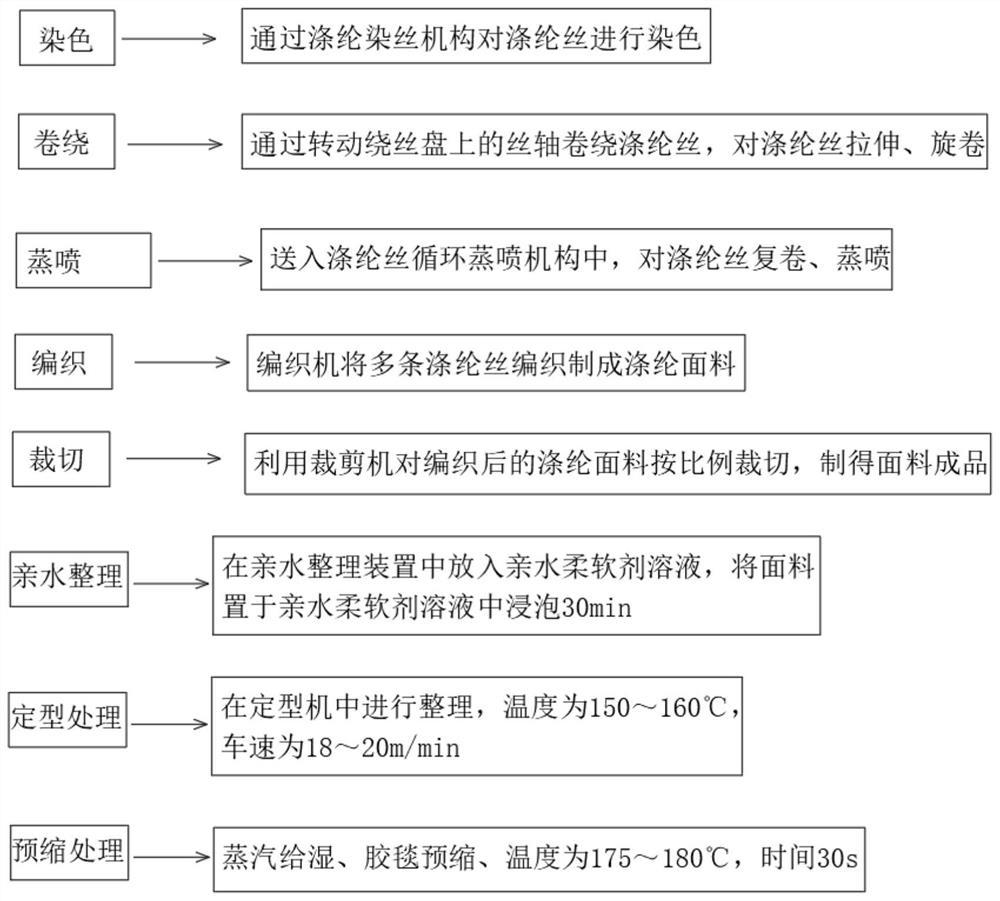

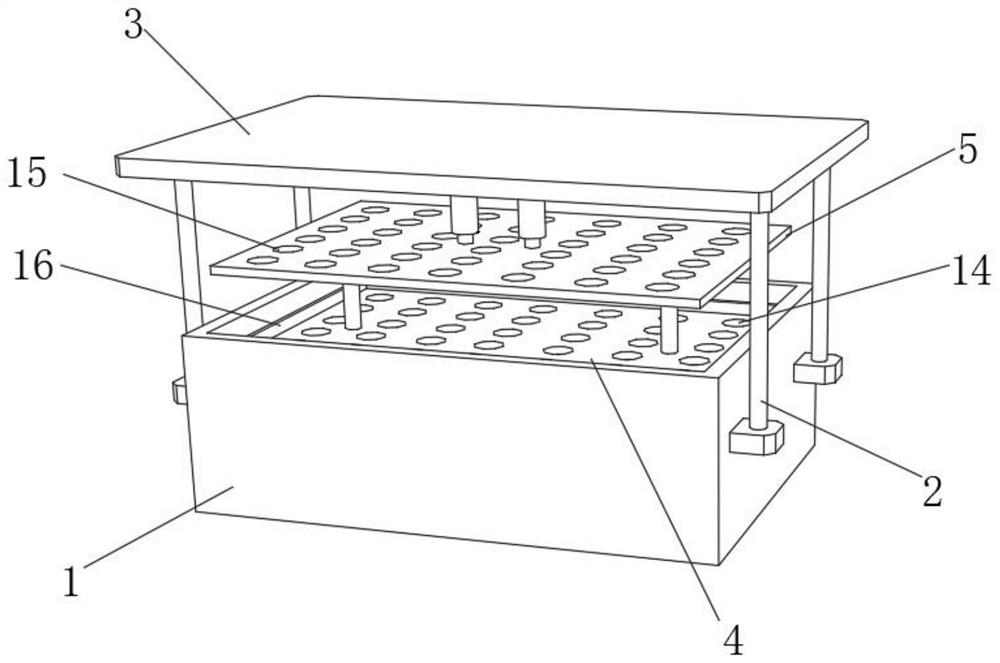

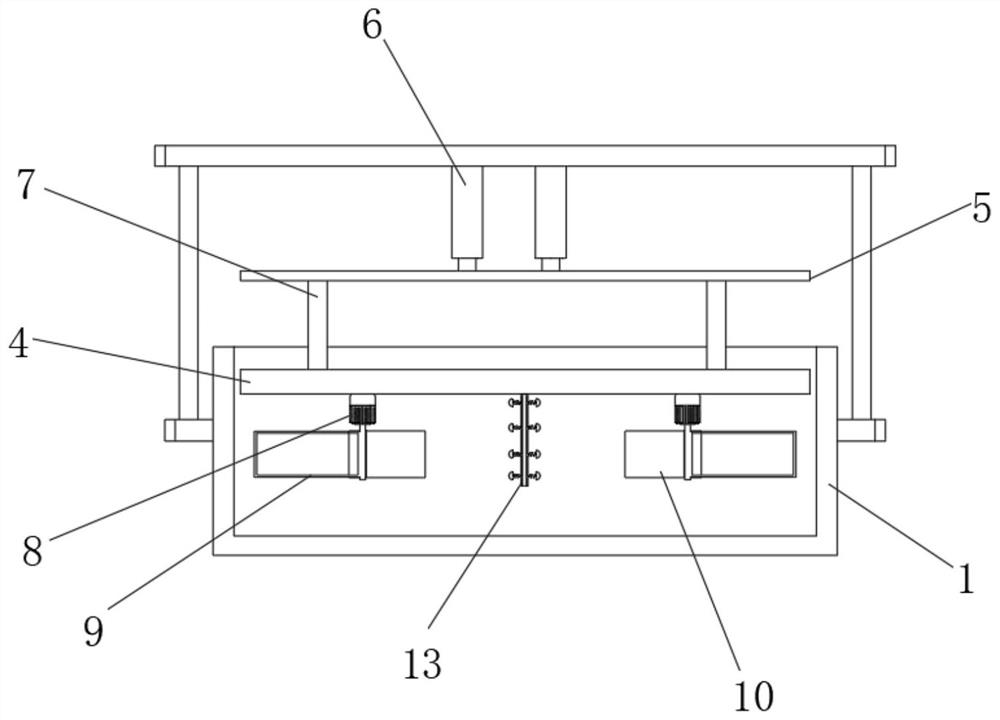

[0041] refer to Figure 1-6 , an efficient clothing processing technology, comprising the following steps:

[0042] S1. Dyeing: Prepare the required dyeing solution in the polyester silk dyeing mechanism, and dye each polyester filament separately through the polyester silk dyeing mechanism;

[0043] S2. Winding: After dyeing and finishing, the polyester yarn is wound by rotating the silk shaft on the wire reel, and the polyester yarn is stretched and coiled;

[0044] S3, steaming and spraying: the polyester yarn after winding is sent to the polyester yarn circulating steaming and spraying mechanism, and the polyester yarn is rewound and steamed and sprayed;

[0045] S4, weaving: import the polyester yarn after rewinding into the knitting machine, and the knitting machine weaves a plurality of polyester yarns to make polyester fabric;

[0046] S5. Cutting: using a cutting machine to cut the woven polyester fabric in proportion to obtain a finished fabric;

[0047] S6. Hydroph...

Embodiment 2

[0060] S1. Dyeing: Prepare the required dyeing solution in the polyester silk dyeing mechanism, and dye each polyester filament separately through the polyester silk dyeing mechanism;

[0061] S2. Winding: After dyeing and finishing, the polyester yarn is wound by rotating the silk shaft on the wire reel, and the polyester yarn is stretched and coiled;

[0062] S3, steaming and spraying: the polyester yarn after winding is sent to the polyester yarn circulating steaming and spraying mechanism, and the polyester yarn is rewound and steamed and sprayed;

[0063] S4, weaving: import the polyester yarn after rewinding into the knitting machine, and the knitting machine weaves a plurality of polyester yarns to make polyester fabric;

[0064] S5. Cutting: using a cutting machine to cut the woven polyester fabric in proportion to obtain a finished fabric;

[0065] S6. Hydrophilic finishing: carry out hydrophilic finishing on the fabric, put the hydrophilic softener solution in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com