800MPa steel based on multi-mode thin slab continuous casting and rolling production line and production method thereof

A thin slab continuous casting and production method technology, applied in the field of iron and steel, can solve the problems of large fluctuations in precision and mechanical properties, and achieve the effects of high dimensional accuracy, uniform performance, and small strength fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

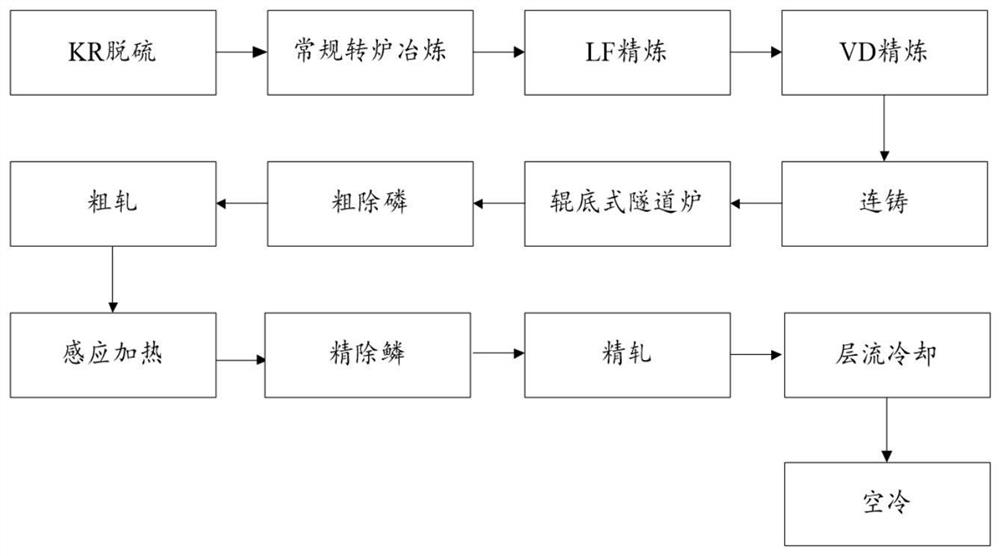

[0079] A kind of 800MPa steel based on multi-mode thin slab continuous casting and rolling production line, made by the following method:

[0080] (1) The target molten steel is obtained through KR desulfurization, conventional converter smelting, LF furnace and VD furnace double refining treatment. In terms of mass fraction, the chemical composition of the molten steel is:

[0081] C: 0.03~0.15%, Si: ≤0.05%, Mn: 1.3~2.1%, AI: 0.02~0.35%, P: ≤0.010, S: ≤0.005, Nb: 0.010~0.10%, Mo: 0.10-0.30% , Ti: 0.015-0.15%, Cr: 0.1-0.5%, N: ≤0.005%, and the rest are Fe and unavoidable impurities.

[0082] (2) The molten steel is continuously cast into a slab: the casting speed of the slab is 3.5-6.5m / min, and the thickness of the slab is 110-123mm.

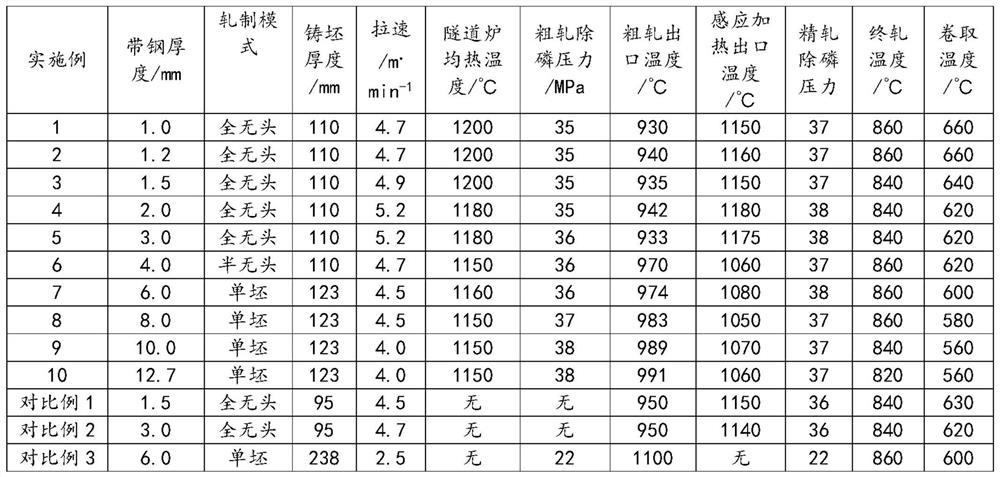

[0083] (3) The soaking temperature of the slab in the tunnel furnace of the multi-mode thin slab continuous casting and rolling production line is 1150-1200 ° C, and the rough phosphorus removal is carried out before the rough rolling, the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com