Pure natural compound amino acid small molecule active peptide extracted from plants and extraction method, preparation and application thereof

A technology of small molecule active peptides and compound amino acids, which is applied in the preparation methods of peptides, preparations for skin care, applications, etc., to achieve the effects of large sample loading, safe use and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

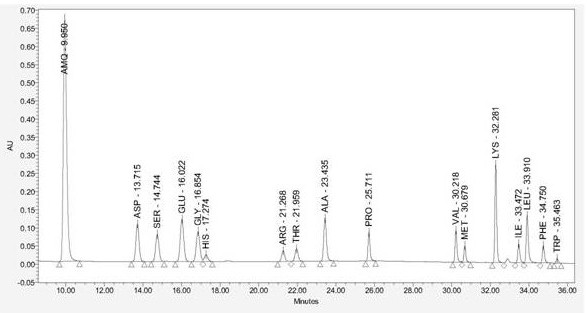

Image

Examples

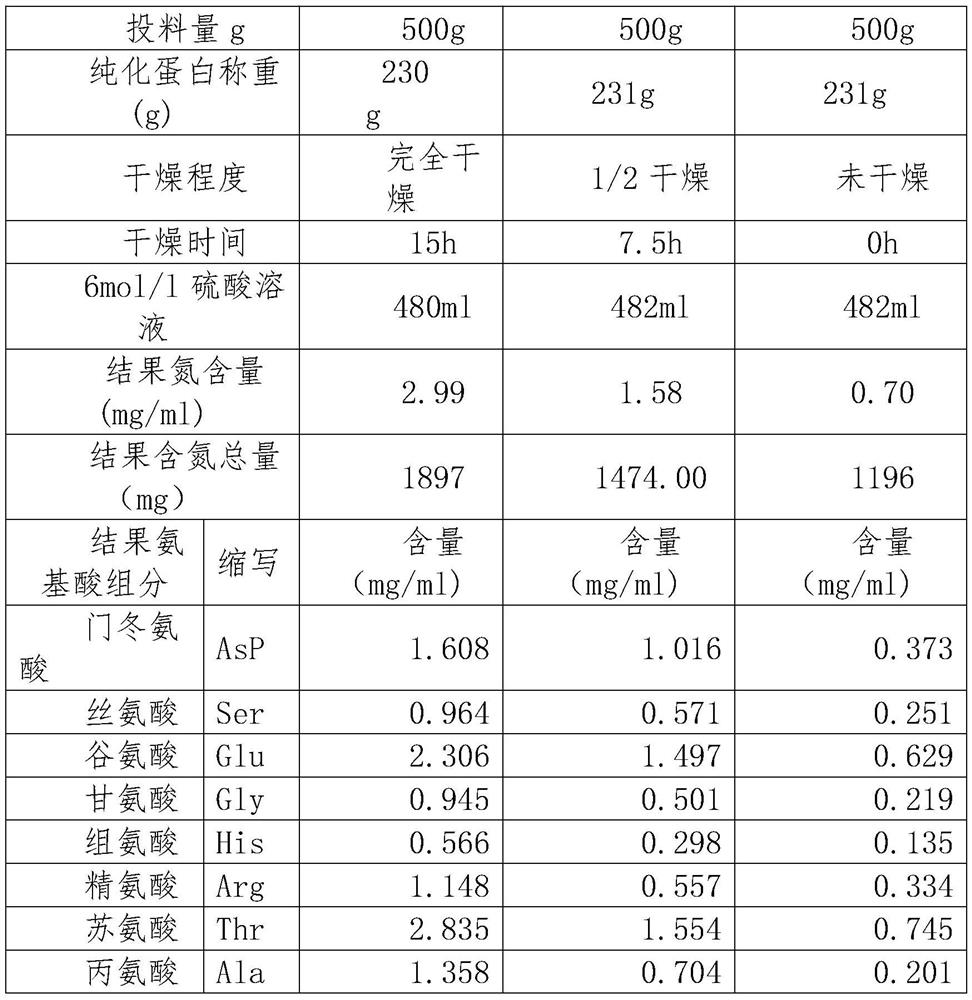

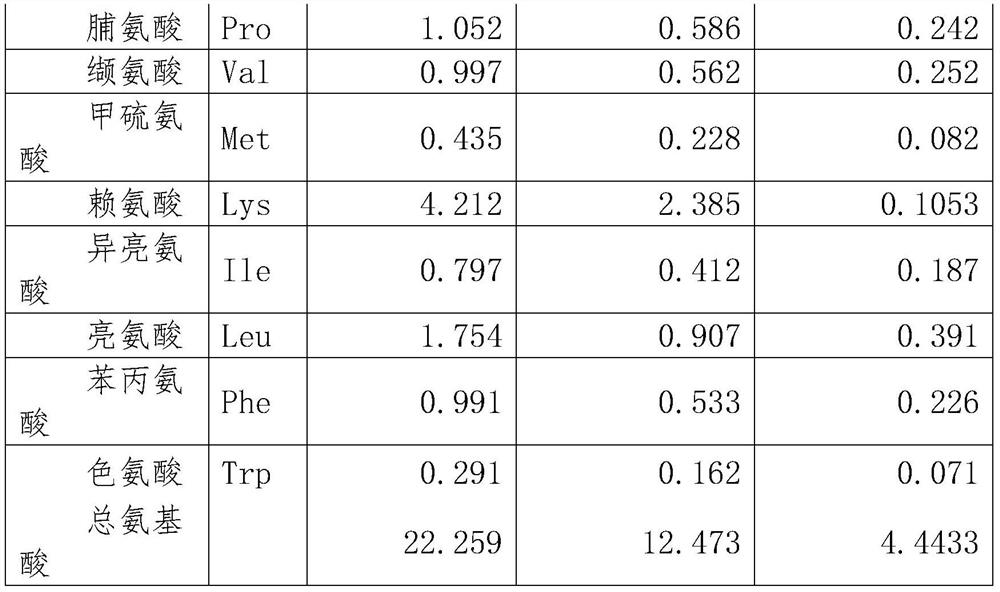

Embodiment 1

[0041] S001 Preparation of purified protein: Take 50kg of dried kudzu rice, crush it, add 100kg of purified water, pour it into an extraction tank, heat it to 75±2°C, keep it warm for 15min, add 250ml of concentrated hydrochloric acid, stir well, cool down to 10°C, release the extraction The solution was centrifuged at 3000r / min, the supernatant was discarded, and the precipitate was collected to obtain the precipitated protein.

[0042] S002 Drying of purified protein: Take the above-mentioned precipitated protein and spread it on a smooth and clean flat stainless steel container, flatten the surface so that the thickness is about 1 cm, place it in a blast drying oven, and heat and dry it in a sealed environment at 78±2°C for 16 Hours, pulverized to obtain dry powder kudzu rice crude protein.

[0043] S003 Acid hydrolysis: Get the above-mentioned dried Gexianmi crude protein and add 6mol sulfuric acid concentration 2000ml per 1kg of dry Gexianmi crude protein, 110±5°C, hydrol...

Embodiment 2

[0048] S001 Preparation of purified protein: Take 50kg of dried kudzu rice, crush it, add 200kg to purify it, pour it into an extraction tank, heat it to 80±2°C, keep it warm for 20min, add 300ml of concentrated hydrochloric acid, stir well, cool down to 20°C, and release the extract , centrifuge at 4000r / min, discard the supernatant, and collect the precipitate to obtain the precipitated protein.

[0049] S002 Drying of purified protein: Take the above-mentioned precipitated protein and spread it on a smooth and clean flat stainless steel container, flatten the surface so that the thickness is about 2 cm, place it in a blast drying oven, and heat and dry it in a sealed environment at 80±2°C for 20 Hours, pulverized to obtain dry powder kudzu rice crude protein.

[0050] S003 Acid hydrolysis: Get the above-mentioned dry kudzu rice crude protein and add 6mol sulfuric acid concentration 2500ml per 1kg of dry kudzu rice crude protein, 120±5°C, hydrolyze for 9h, dilute with 2 time...

Embodiment 3

[0055] S001 Preparation of purified protein: Take 50kg of dried kudzu rice, crush it, add 300kg to purify it, pour it into an extraction tank, heat it to 85±2°C, keep it warm for 30min, add 350ml of concentrated hydrochloric acid, stir well, cool down to 30°C, and release the extract , centrifuge at 5000r / min, discard the supernatant, and collect the precipitate to obtain the precipitated protein.

[0056] S002 Drying of purified protein: Take the above-mentioned precipitated protein and spread it on a smooth and clean flat stainless steel container, flatten the surface so that the thickness is about 3 cm, put it in a blast drying oven, and heat and dry it in a sealed environment at 88±2°C for 26 Hours, pulverized to obtain dry powder kudzu rice crude protein.

[0057] S003 acid hydrolysis: get the above-mentioned dry kudzu rice crude protein and add 6mol sulfuric acid concentration 3000ml per 1kg of dry kudzu rice crude protein, 125 ± 5 ℃, hydrolyze 10h, dilute with 2 times o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com