Concrete release agent and preparation method thereof

A technology of concrete release agent and emulsifier, which is applied in manufacturing tools, petroleum industry, ceramic molding machines, etc. It can solve the problems of easily stained steel bars of construction operators, oil spots on structures, long drying time, etc., and achieve abundant production , less adhesion, short drying and film-forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

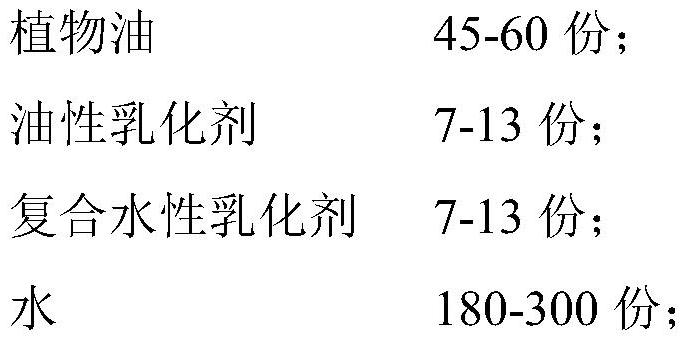

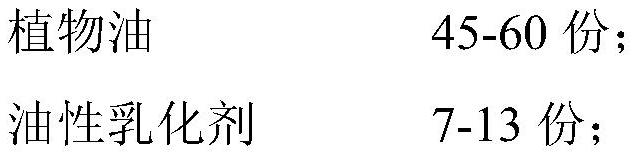

[0039] The present embodiment provides a kind of concrete release agent, and the raw material component of described concrete release agent comprises (calculated by mass parts, by every part=10g batching):

[0040]

[0041] Wherein, the composition of composite aqueous emulsifier is: the mass parts of TW-80, OP-10 and SDBS are respectively 4.4 parts, 4.2 parts and 2 parts. That is, the parts by mass of each emulsifier are: S-60:TW-80:OP-10:SDBS=10:4.4:4.2:2.

[0042] Its preparation method is as follows:

[0043] (1) Mix the oily emulsifier S-60 with rapeseed oil and stir until they merge to obtain solution A; mix the composite water-based emulsifiers (TW-80, OP-10 and SDBS) with water and stir until they merge, Obtain solution B;

[0044] (2) Add solution B dropwise to solution A, stir while adding dropwise, add preservative (triethanolamine) and stabilizer (xanthan gum) after dropwise addition, and configure it as a concrete release agent. Wherein, the temperature of t...

Embodiment 2

[0047] This embodiment provides a concrete release agent, the raw material formula and preparation method of the concrete release agent are basically the same as in Example 1, the only difference is that the composition of the composite water-based emulsifier is: TW-80, OP-10 and The mass parts of SDBS are 4 parts, 4 parts and 2 parts respectively, that is, the mass parts of each emulsifier is: S-60: TW-80: OP-10: SDBS=10:4:4:2.

[0048] After calculation and testing, the HLB value of the obtained concrete release agent is 9.3, and the stable days of the obtained concrete release agent are 75 days; the adhesion amount is 4.9g / m2 .

Embodiment 3

[0050] This embodiment provides a concrete release agent, the raw material formula and preparation method of the concrete release agent are basically the same as in Example 1, the only difference is that the composition of the composite water-based emulsifier is: TW-80, OP-10 and The parts by mass of SDBS are 4.8 parts, 4.4 parts and 2 parts respectively, that is, the parts by mass of each emulsifier are: S-60: TW-80: OP-10: SDBS=10:4.8:4.4:2.

[0051] Through calculation and test, the HLB value of the obtained concrete release agent is 9.6, and the stable days of the obtained concrete release agent is 60d; the adhesion amount is 6.0g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com