Preparation method of high-performance ultra-large and ultra-thick carbon/carbon composite material

A carbon composite material, high-performance technology, applied in the field of preparation of high-performance ultra-large and ultra-thick carbon/carbon composite materials, can solve the problems of low mechanical and thermal conductivity, low product qualification rate, high linear expansion coefficient, etc., and achieve thermal conductivity High, high product qualification rate, low linear expansion coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

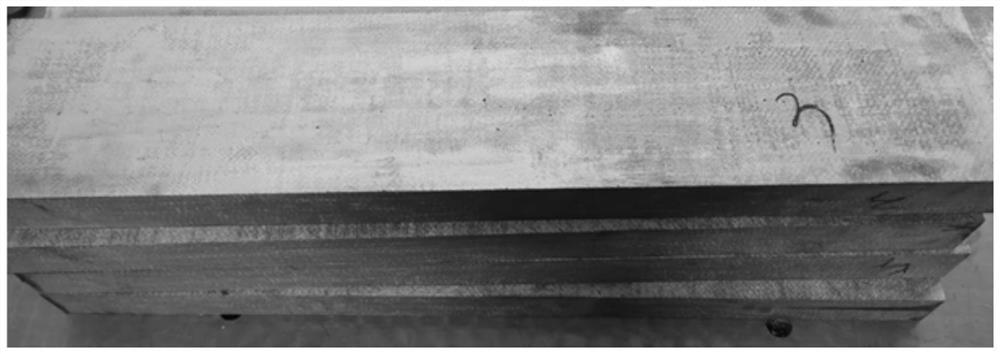

Embodiment 1

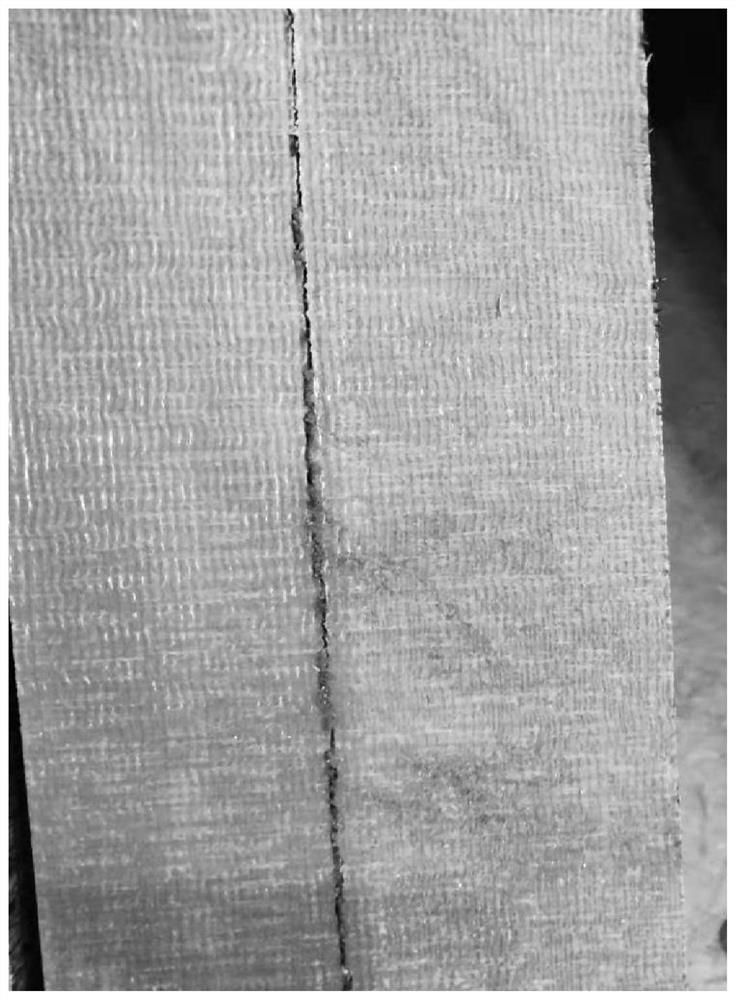

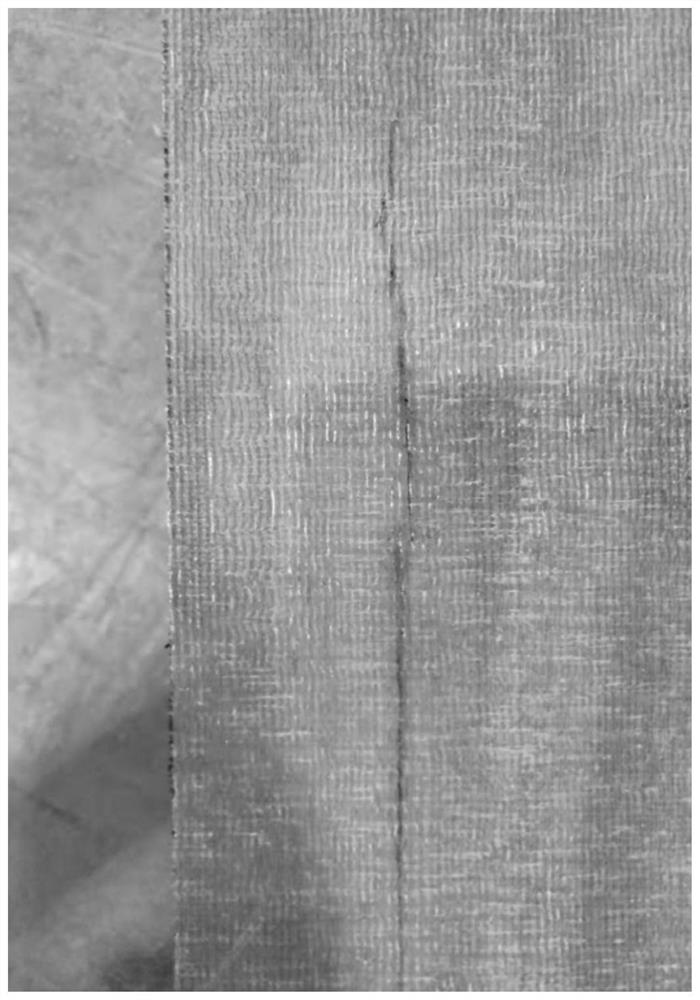

[0043] a. Prepare 15 pieces of carbon fiber prefabricated body. The carbon fiber prefabricated body is a 2D needle-punched structure. A layer of PANCF non-weft cloth and a layer of PANCF non-weft cloth mesh tire are alternately laid, and the non-weft cloth is alternately laid at 0° / 90°. Made by continuous needle punching; the size of the carbon fiber preform is 1370mm×390mm×190mm, and the density is 0.58g / cm 3 ;

[0044] b. Carry out primary graphitization treatment on the carbon fiber prefabricated body to obtain the carbon fiber green body; put the carbon fiber prefabricated body into the heat treatment furnace, first evacuate, raise the temperature to 2000°C and keep it warm for 2 hours, during which argon gas is filled, and the furnace pressure is 0.2-3KPa , to graphitize the carbon fiber preform, and then cool it naturally with the furnace;

[0045] c. Carry out CVD densification treatment on the carbon fiber green body, put the carbon fiber green body into a chemical va...

Embodiment 2

[0056] a. Prepare 35 pieces of carbon fiber prefabricated body. The carbon fiber prefabricated body is a 2D needle-punched structure. A layer of PANCF non-weft cloth and a layer of PANCF non-weft cloth mesh are alternately laid, and the non-weft cloth is alternately laid at 0° / 90°. Made by continuous needle punching; the size of the carbon fiber preform is 1240mm×340mm×170mm, and the density is 0.45g / cm 3 ;

[0057] b. Carry out primary graphitization treatment on the carbon fiber prefabricated body to obtain the carbon fiber green body; put the carbon fiber prefabricated body into the heat treatment furnace, first evacuate, raise the temperature to 2000°C and keep it warm for 2 hours, during which argon gas is filled, and the furnace pressure is 0.2-3KPa , to graphitize the carbon fiber preform, and then cool it naturally with the furnace;

[0058] c. Carry out CVD densification treatment on the carbon fiber green body, put the carbon fiber green body into a chemical vapor d...

Embodiment 3

[0069] a. Prepare 50 carbon fiber prefabricated bodies. The carbon fiber prefabricated body is a 2D needle-punched structure. A layer of PANCF non-weft cloth and a layer of PANCF non-weft cloth mesh are alternately laid, and the non-weft cloth is alternately laid at 0° / 90°. It is made by continuous needle punching; the size of the carbon fiber preform is 1015mm×315mm×165mm, and the volume density of the felt body is 0.35g / cm 3 ;

[0070] b. Carry out primary graphitization treatment on the carbon fiber prefabricated body to obtain the carbon fiber green body; put the carbon fiber prefabricated body into the heat treatment furnace, first evacuate, raise the temperature to 2000°C and keep it warm for 2 hours, during which argon gas is filled, and the furnace pressure is 0.2-3KPa , to graphitize the carbon fiber preform, and then cool it naturally with the furnace;

[0071] c. Carry out CVD densification treatment on the carbon fiber green body, put the carbon fiber green body i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com