Method and reaction device for degrading organic wastewater

An organic wastewater and reaction technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem of unsatisfactory effect of high concentration refractory wastewater, achieve high TOC removal rate and improve degradation ability. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

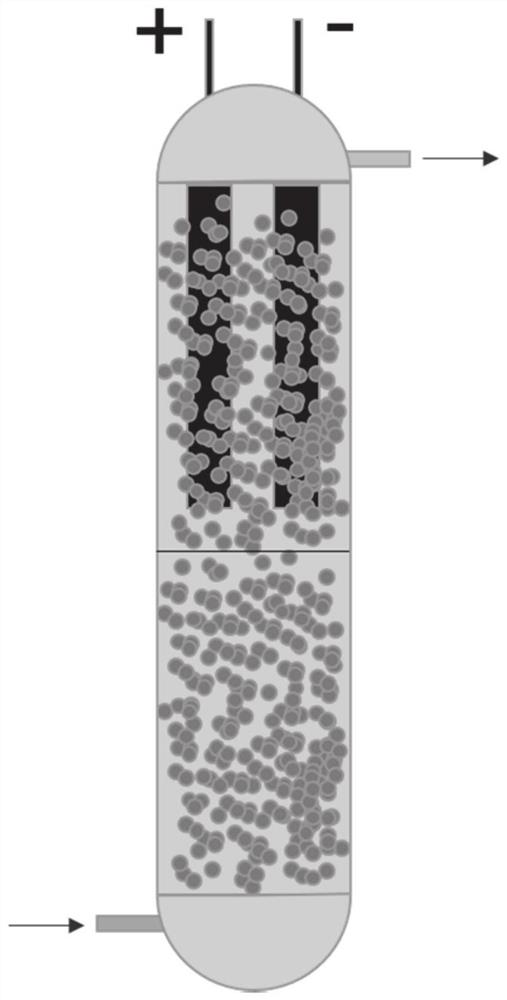

[0186] Embodiment 1 continuous reaction

[0187] The m-cresol concentration is 10000ppm wastewater (COD in the wastewater is 23000mg / L), the wastewater flow rate is 5t / h, the anode is selected as a platinum electrode (PtTi-01, purchased from Dalian Keduo Environment), and the cathode is ruthenium titanium oxide The material electrode (RuTi-01, purchased from Dalian Keduo Environment), chooses a negative and positive arc-shaped front facing and coaxial arrangement with the reactor, and the electrode installation method is that the electrode is at the lower end of the reactor (WEO+ WAO), without catalyst, sodium nitrate dosage in waste water is 0.5wt%, air flow 450Nm 3 / h, pressurize waste water and oxygen and mix respectively to obtain a gas-liquid mixture, heat the gas-liquid mixture to raise the temperature, and then pass the high-temperature and high-pressure gas-liquid mixture into the reactor with a reaction temperature of 250°C and a reaction pressure of 6.5 MPa (ie the ...

Embodiment 2

[0193] Embodiment 2 continuous reaction

[0194] The wastewater with m-cresol concentration of 10000ppm (COD in the wastewater is 23000mg / L), the wastewater flow rate is 5t / h, the anode is selected as a platinum electrode (PtTi-02, Dalian Keduo Environment), and the cathode is a ruthenium titanium oxide electrode (RuTi-03, Dalian Keduo Environment), choose the way that one yin and one yang are opposite to each other in an arc shape and arranged coaxially with the reactor. The combination of the catalyst and the electrode is that the catalyst and the electrode are at the lower end of the reactor (CWEO +WAO), the catalyst added is a spherical Fe / alumina catalyst (KD-FeAl, Dalian Keduo Environment), the dosage of sodium nitrate in the wastewater is 0.1wt%, and the air flow rate is 450Nm 3 / h, pressurize waste water and oxygen and mix respectively to obtain a gas-liquid mixture, heat the gas-liquid mixture to raise the temperature, and then pass the high-temperature and high-press...

Embodiment 3

[0199] Embodiment 3 continuous reaction

[0200] The concentration of isophorone is 5000ppm wastewater (COD in the wastewater is 12670mg / L), the wastewater flow rate is 1t / h, the anode is selected as a lead dioxide electrode (PbTi-03, Dalian Keduo Environment), and the cathode is ruthenium titanium Oxide electrode (RuTi-03, Dalian Keduo Environment), choose a positive and negative anode as a ring, and the cathode is arranged in a ring outside, and the electrode installation method is that the electrode is at the upper end of the reactor (WAO+WEO) , no catalyst, the dosage of sodium nitrate and sodium sulfate (mass ratio 1:1) in the wastewater is 1wt%, and the air flow rate is 50Nm 3 / h, pressurize waste water and oxygen and mix respectively to obtain a gas-liquid mixture, heat the gas-liquid mixture to raise the temperature, and then pass the high-temperature and high-pressure gas-liquid mixture into the reactor, and the waste water space velocity is 2h -1 , the reaction tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com