3D printing nozzle structure for realizing supercooling forming of continuous fiber self-reinforced composite material

A reinforced composite material and 3D printing technology, applied in the direction of additive processing, coating devices, etc., can solve the problems of thermal damage of the reinforced phase, long molding cycle, narrow processing window, etc., to solve research difficulties and increase processing temperature Interval, fast and efficient manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

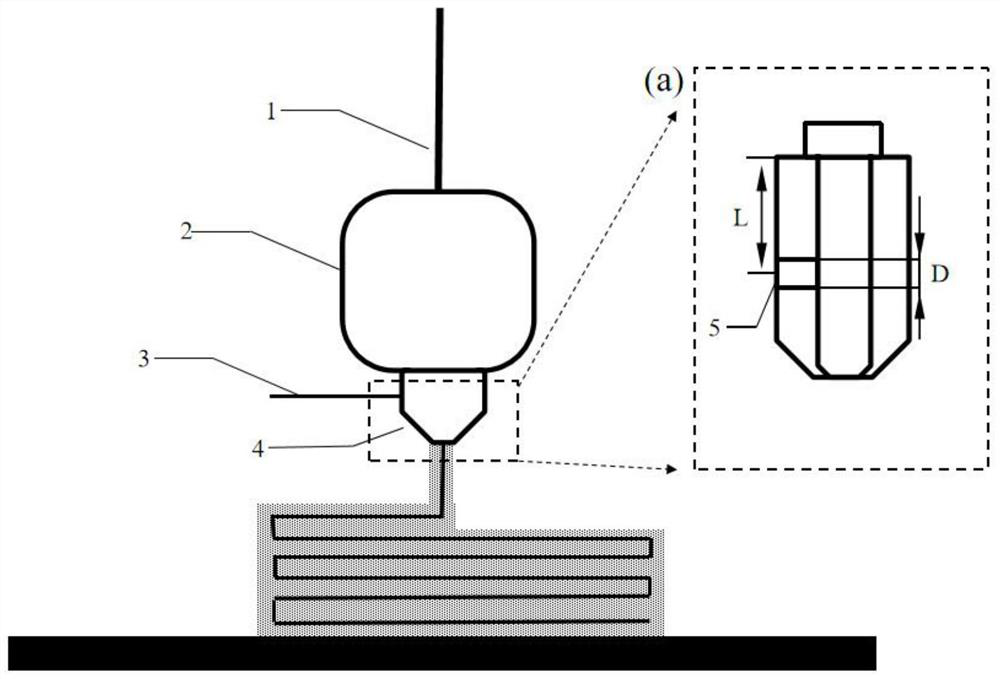

[0024] refer to figure 1 , a 3D printing nozzle structure for realizing supercooled forming of continuous fiber self-reinforced composite materials, including a liquefier 2, the lower end of the liquefier 2 is connected to a nozzle 4, the matrix phase 1 enters from the upper end of the liquefier 2, and is heated by the liquefier 2 to become molten state, enter the nozzle 4, and cool down to below the melting point of the matrix phase 1 during the process from the liquefier 2 to the nozzle 4 without crystallization, forming a supercooled melt;

[0025] The side of the nozzle 4 is provided with a fiber hole 5, the reinforcement phase 3 enters the supercooled melt of the matrix phase 1 through the fiber hole 5, and the reinforcement phase 3 wraps the matrix phase 1, extrudes from the nozzle 4 and solidifies after being cooled.

[0026] The reinforcing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com