Agricultural lotus seed processing device utilizing rotary friction

A technology of rotating friction and processing devices, which is applied in agriculture, grinding drive devices, agricultural machinery and equipment, etc., can solve the problems of easy damage to seed germs, inconvenient operation, slipping of lotus seeds, etc., to avoid artificial injuries, improve processing efficiency, The effect of increasing germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

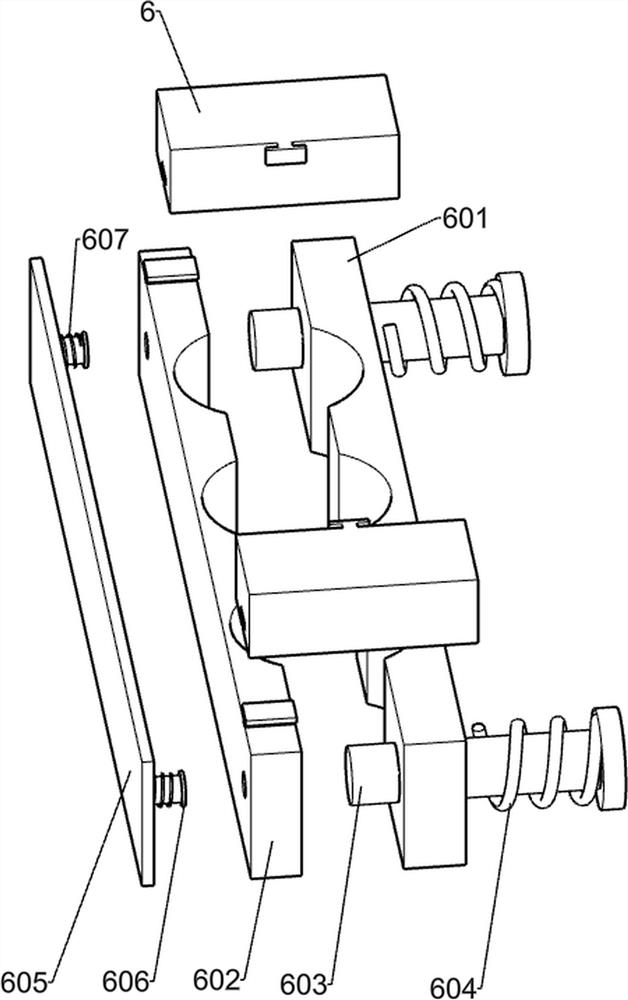

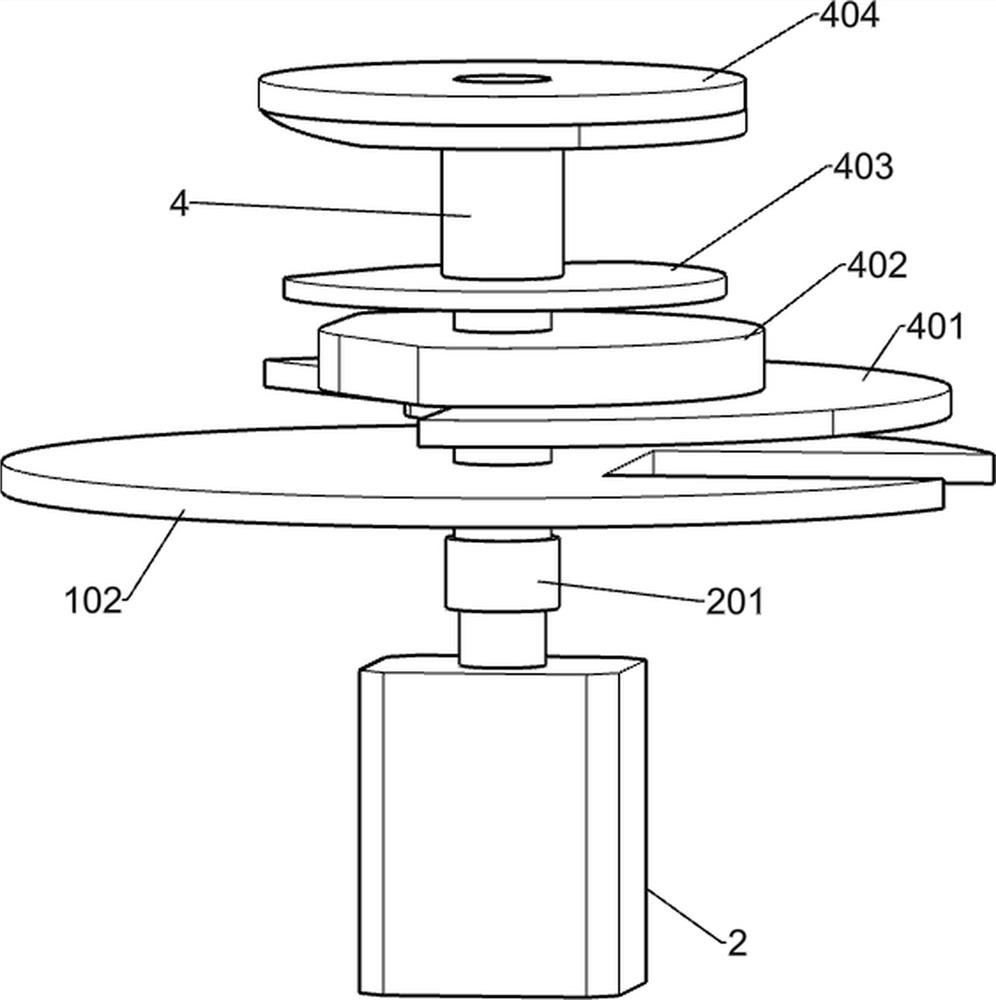

[0031] Such as figure 1 with Figure 4 As shown, an agricultural lotus seed processing device utilizing rotational friction includes a base 1, a pillar 101, a tray 102, an outer barrel cover 103, a motor 2, a coupling 201, a quantitative feeding assembly and a grinding assembly, and the base 1 A pillar 101 and a motor 2 are installed on the upper side, the motor 2 is located at the center of the base 1, four pillars 101 are evenly arranged around the motor 2, the upper end of the pillar 101 is fixedly connected with a tray 102, the right side of the tray 102 is provided with a gap, and the outer The opening side of the barrel cover 103 is fixedly connected to the side wall of the outer ring of the tray 102, the grinding assembly is connected to the output shaft of the motor 2 through a coupling 201, the grinding assembly is connected to the tray 102 in rotation, and the quantitative cutting assembly is fixedly connected to the outer barrel cover 103. On the inner wall, the qu...

Embodiment 2

[0034] Such as figure 2 with image 3As shown, on the basis of Embodiment 1, the quantitative blanking assembly includes a connecting block 3, a material box 301, a feeding port 302, a small support plate 303, a first spring 304 and a material blocking plate 305, and the connecting block 3 The right side is fixedly connected on the inner side wall of the outer barrel cover 103, and the left side of the connection block 3 is fixedly connected with a material box 301. The inside of the material box 301 is hollow and three feeding ports 302 are arranged side by side on the upper side. The bottom side of the material box 301 is provided with three A lower circular hole 306 corresponding to the feeding opening 302, two small support plates 303 are symmetrically arranged on the front and rear sides of the outside of the material box 301, and two front and rear adjacent first springs are consolidated on the left side of the material box 301 304, the material blocking plate 305 is c...

Embodiment 3

[0045] Such as Figure 9 As shown, on the basis of Embodiment 2, it also includes a connecting rod 8 and a brush 801, the lower end of the connecting rod 8 is fixedly connected to the upper side of the tray 102, and the upper end of the connecting rod 8 is fixedly connected with a brush 801, and the brush 801 is fixedly connected to the upper end of the connecting rod 8. 801 is in contact with the grinding disc 401 .

[0046] When the grinding disc 401 is working, some lotus seed skin debris will remain on it, and when the grinding disc 401 is rotating, the brush 801 will clean these remaining debris.

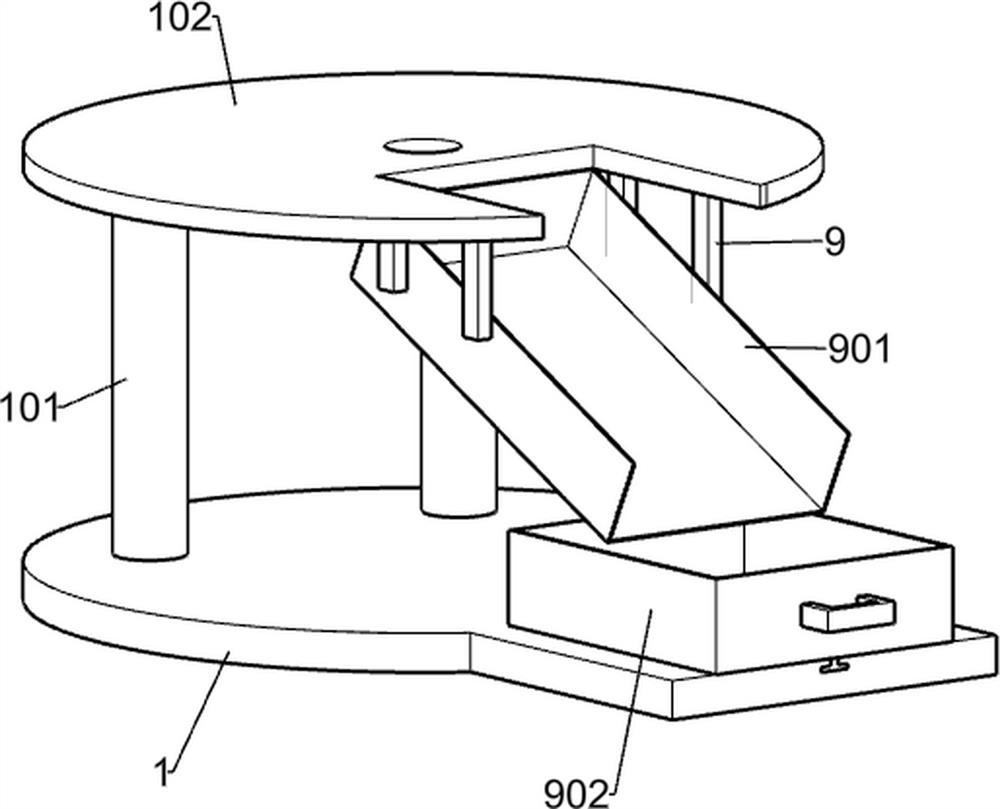

[0047] Such as Figure 10 As shown, it also includes a fixed rod 9, a blanking bin 901 and a material receiving drawer 902. There are four fixed rods 9, and the fixed rods 9 are arranged symmetrically along the gap of the tray 102. On the bottom side, the lower end of the fixed rod 9 is fixedly connected with a blanking bin 901 , and the receiving drawer 902 is slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com