Assembly line for producing wooden boxes

An assembly line and wooden box technology, which is applied to machine tools, wood processing equipment, sawing equipment, etc., which are suitable for grinding workpiece planes, and can solve the problem that debris is easy to splash around without a recovery mechanism and a dust guide structure. To achieve the effect of improving the adhesion effect, quick and effective dust cleaning treatment, and maintaining the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

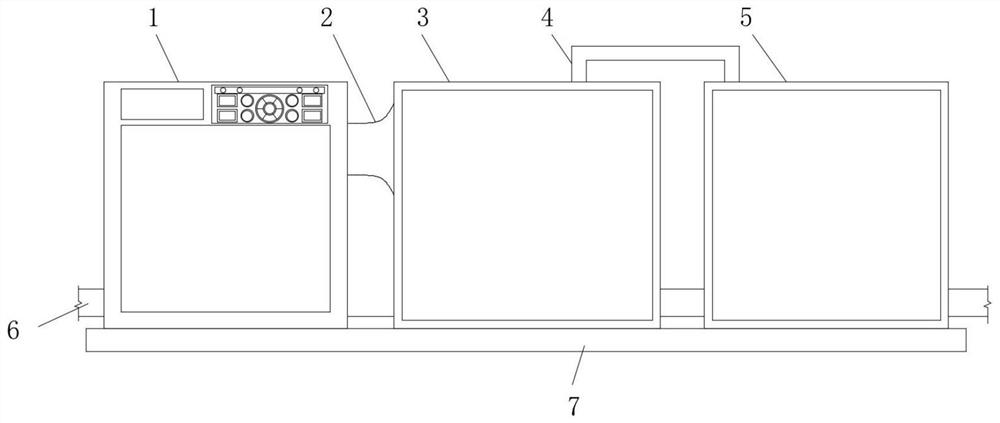

[0034] A pipeline for producing wooden boxes, such as Figure 1-7 As shown, including the wood bar grinding machine 1, the wood cutting machine 3, the air dryer 5, the base 7, the grinding roller 13, the dust capture assembly 14, the drive worm 17, and the positioning assembly 28, the top of the base 7 from left to right respectively Fixed wooden plate grinding machine 1, the wood cutting machine 3 and the wind dryer 5, the wood plate grinding machine 1, the inner part of the wood cutting machine 3 and the wind dryer 5 are arranged in the interior of the air dryer 5, and the drive chain plate 6 is opened The bottom groove 24 is provided with a top groove and a positioning component 28 in the top groove;

[0035] The positioning assembly 28 includes a side top spring 281 and a moving positioning shaft 282;

[0036] Wherein, the side top spring 281 is fixedly mounted on the inner wall of the top groove, and the moving positioning shaft 282 is slidably mounted inside the top groove, a...

Embodiment 2

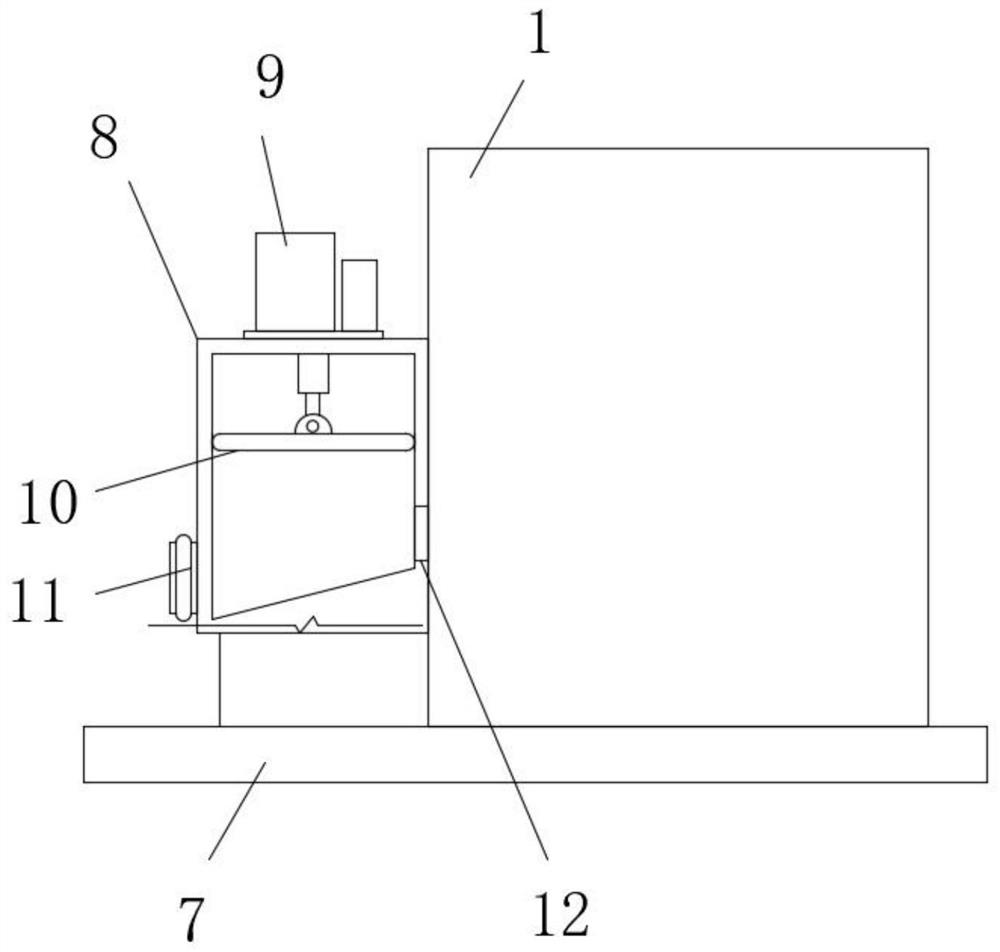

[0040] A pipeline for producing a wooden box, which is different from that of Example 1, such as Figure 1-8As shown, the rear side outer wall of the wood board grinding machine 1 is fixed to the attachment of the side recovery machine 8, and the connection between the wood board grinding machine 1 and the side recovery machine 8 is opened, and the side recovery machine 8 The top is fixedly mounted having a hydraulic press 9, and the output shaft of the hydraulic press 9 is rotated by the rotating shaft, and the outer wall of the side recovery machine 8 is fixedly mounted on the outer wall of the side recovery machine 8.

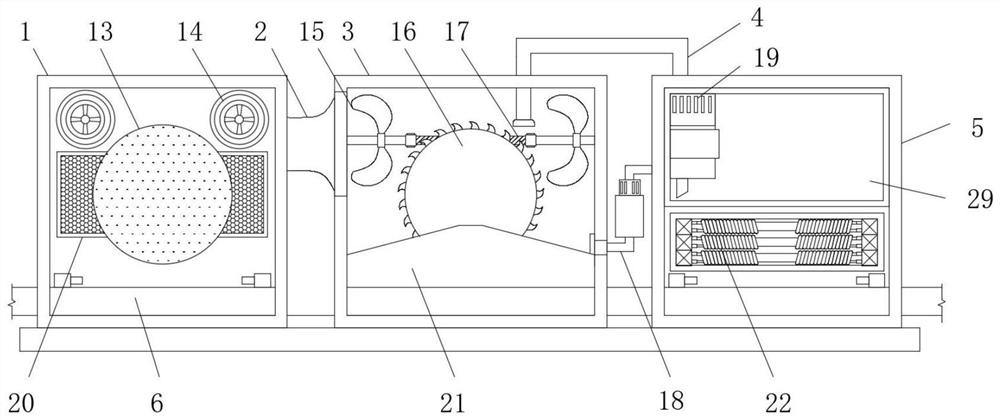

[0041] The rear side outer wall of the cutting tray 16 is fixedly mounted having a drive worm wheel, and the inside of the wood cutting machine 3 is rotated by a sleeve to be mounted with a drive worm 17, and a side blow fan 15 is fixedly mounted in an outer fixation of the drive worm 17;

[0042] The wood board grinding machine 1 is connected between the wooden ...

Embodiment 3

[0045] A pipeline for producing a wooden box, which is different from that of Example 1, such as Figure 1-8 As shown, the inside of the wood board grinding machine 1 is rotated by the second lateral belt shaft 27, and the first lateral belt shaft 26 is connected between the second side belt shaft 27 by a transmission belt 25;

[0046] The dust capture assembly 14 is composed of a mounting cover 141, a dust collecting inner post 142, and a blade plate 146, and the mounting spindle 147, and the internal rotation of the mounting cover 141 is rotated, and the inner column 142 is mounted, the airflow column The outer outer wall of 142 is fixedly mounted by the connecting rod, and the outer portion of the dust collecting inner column 142 is provided with a viscous mount 144, and the side mount 144 is fixedly mounted, the side mounting sheet 144. The side rotation is attached to the mounting spindle 147, and the mounting main shaft 147 is fixedly mounted, and the sidewalls, which are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com