Rare-earth-element-doped defective UiO-66 material as well as preparation method and application thereof

A rare earth element, uio-66 technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

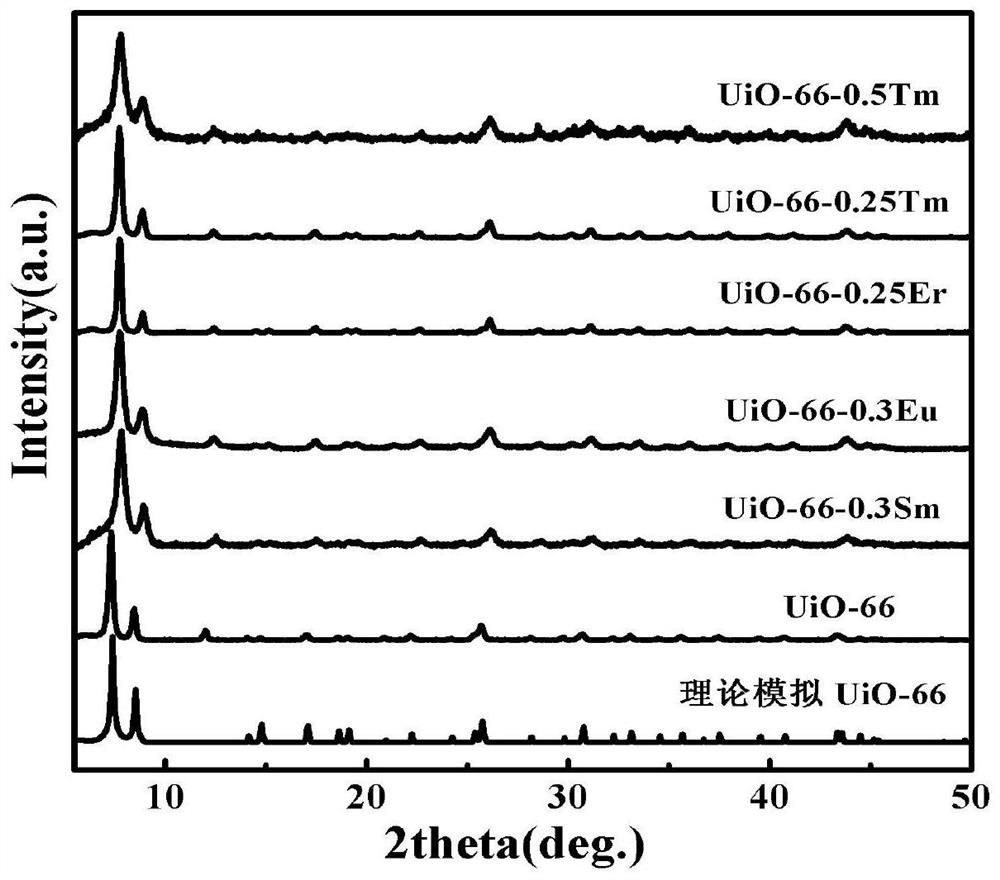

[0024] The invention provides a method for preparing a defect UiO-66 material doped with rare earth elements, comprising the following steps:

[0025] Mixing zirconium tetrachloride, terephthalic acid, N,N-dimethylformamide and rare earth oxides, and subjecting the resulting mixture to a solvothermal reaction to obtain defect UiO-66 materials doped with rare earth elements;

[0026] The rare earth oxide is Sm 2 o 3 、Eu 2 o 3 、Er 2 o 3 or Tm 2 o 3 ;

[0027] The molar ratio of the zirconium tetrachloride, terephthalic acid and rare earth oxide is 1:1:(0.25-0.5).

[0028] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0029] In the invention, zirconium tetrachloride, terephthalic acid, N,N-dimethylformamide and rare earth oxide are mixed, and the obtained mixture is subjected to solvothermal reaction to obtain defect UiO-66 material doped with rare earth element.

[0030] In the ...

Embodiment 1

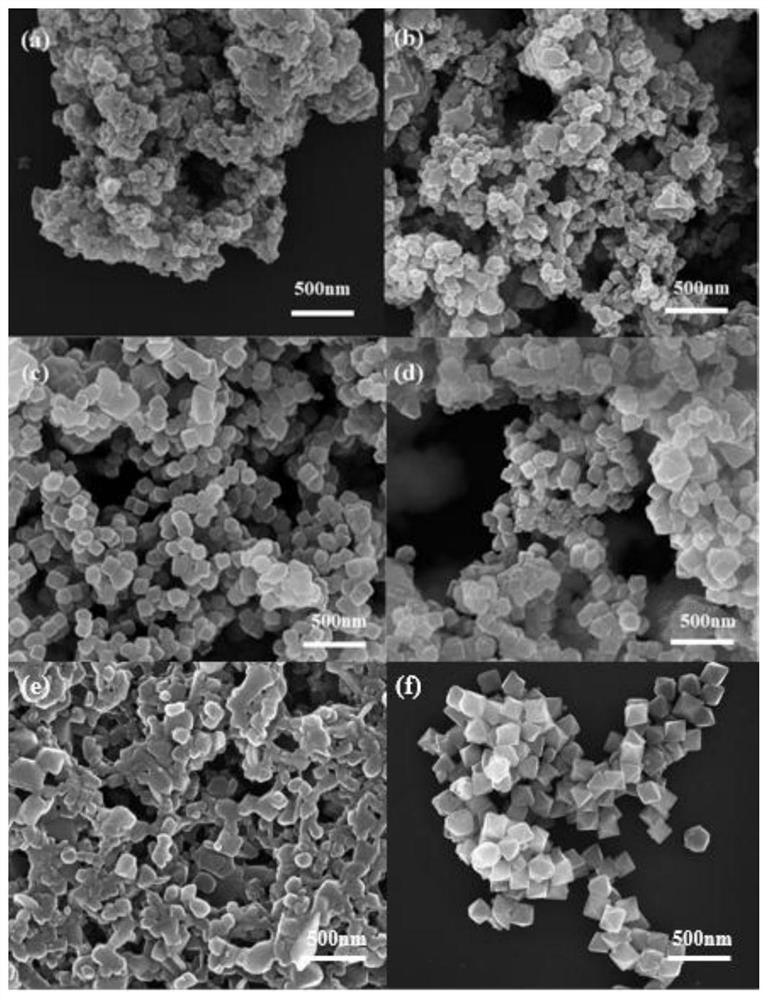

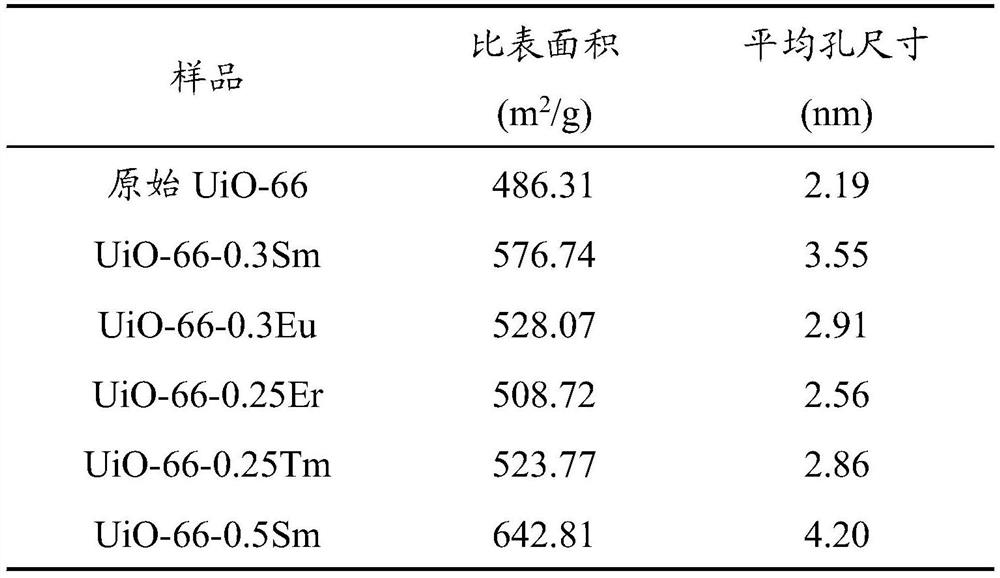

[0044] Preparation of UiO-66-0.3Sm

[0045] Weigh 2mmol of zirconium tetrachloride and dissolve it in 100mL of DMF solvent evenly, add 2mmol of terephthalic acid after ultrasonic stirring for 30min, and continue ultrasonic stirring for 45min to disperse the solution evenly to obtain an intermediate mixture; then add 0.6mmol of samarium oxide to the above In the intermediate mixture (the molar ratio of zirconium tetrachloride, terephthalic acid and samarium oxide is 1:1:0.3), continue ultrasonic stirring for 30 minutes; then transfer to a 200mL reactor and perform solvothermal reaction in an oven at 120°C for 48 hours After cooling to room temperature and centrifuging, the obtained precipitate was ultrasonically washed three times with anhydrous methanol, each time the amount of anhydrous methanol was 100mL; the filtered product was vacuum-dried in an oven at 130°C, ground and sieved.

Embodiment 2

[0047] Preparation of UiO-66-0.3Eu

[0048] Weigh 2mmol of zirconium tetrachloride and dissolve it uniformly in 100mL DMF solvent, add 2mmol of terephthalic acid after ultrasonic stirring for 30min, and continue ultrasonic stirring for 45min to disperse the solution evenly to obtain an intermediate mixture; then add 0.6mmol of europium oxide to the above In the intermediate mixture (the molar ratio of zirconium tetrachloride, terephthalic acid and europium oxide is 1:1:0.3), continue ultrasonic stirring for 30min; then transfer to a 200mL reactor and perform solvothermal reaction in an oven at 120°C for 48h ; After cooling to room temperature, centrifuge, and ultrasonically wash the obtained precipitate with anhydrous methanol three times to remove the remaining substances in the reaction system, each time the amount is 100mL; the filtered product is vacuum-dried in an oven at 130°C, ground and sieved .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com