Explosion-proof forklift lithium battery and preparation method thereof

A lithium battery and forklift technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery cycle performance that need to be improved, and achieve the effects of improving cycle capacity retention rate, small expansion thickness, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

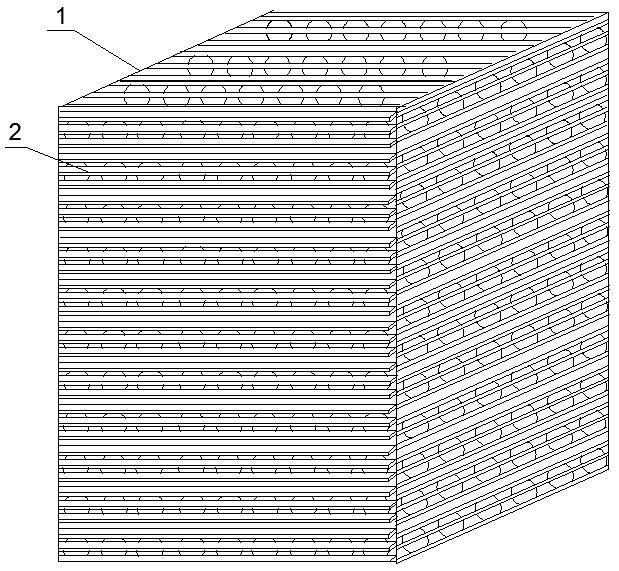

Image

Examples

Embodiment 1

[0044] An explosion-proof lithium battery for forklifts, comprising an explosion-proof casing, a positive electrode arranged in the explosion-proof casing, a negative electrode, an electrolyte and a diaphragm; the positive electrode includes a positive electrode material and a positive current collector, and the negative electrode includes a negative electrode material and a negative current collector, The positive electrode material includes a positive electrode active material, a positive electrode conductive agent, and a positive electrode binder; the negative electrode material includes a negative electrode active material, a negative electrode conductive agent, and a negative electrode binder;

[0045] The positive electrode active material is modified lithium manganate, the positive electrode conductive agent and the negative electrode conductive agent have different components, the positive electrode binder and the negative electrode binder have different components, and ...

Embodiment 2

[0067] This embodiment provides an explosion-proof forklift lithium battery and its preparation method, which is the same as in Embodiment 1, but the difference from Embodiment 1 is that in this embodiment, in the positive electrode material, CNT: PVDF solution: modified lithium manganate :: The weight ratio of solvent NMP is: 1:3.5:13:115.

[0068] The negative electrode conductive agent is a composite conductive agent of SP-P, KS-6, and CNT, and the weight ratio of SP-P:KS-6:CNT is: 1:0.8:1.5.

[0069] The weight ratio of graphene: composite conductive agent: LA132: solvent NMP is: 11: 1.8: 1: 108.

[0070] The electrolyte contains TCP, LiPF 6 , organic solvent, described organic solvent is mixed by EC, EMC, DEC, and the weight ratio of EC:EMC:DEC is 3:3:4, LiPF 6 The concentration of is 1mol / L, and the mass fraction of TCP is 2%.

[0071] The modified lithium manganate is prepared from the following components in parts by weight: 11 parts of lithium manganate, 6 parts of...

Embodiment 3

[0073] This embodiment provides an explosion-proof forklift lithium battery and its preparation method, which is the same as in Embodiment 1, but the difference from Embodiment 1 is that in this embodiment, in the positive electrode material, CNT: PVDF solution: modified lithium manganate : The weight ratio of the solvent NMP is: 1:4:15:120.

[0074] The negative electrode conductive agent is a composite conductive agent of SP-P, KS-6, and CNT, and the weight ratio of SP-P: KS-6: CNT is: 1: 1: 2.

[0075] The weight ratio of graphene: composite conductive agent: LA132: solvent NMP is: 12:2:1:110.

[0076] The electrolyte contains TCP, LiPF 6 , organic solvent, described organic solvent is mixed by EC, EMC, DEC, and the weight ratio of EC:EMC:DEC is 3:3:4, LiPF 6 The concentration of is 1mol / L, and the mass fraction of TCP is 3%.

[0077] The modified lithium manganate is prepared from the following components in parts by weight: 12 parts of lithium manganate, 8 parts of tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com