Lithium battery pole piece preparation method and solid-state lithium battery thereof

A battery pole piece, lithium battery technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve problems such as battery pole piece oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

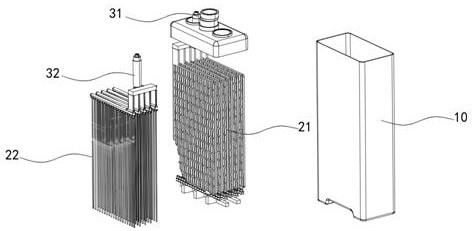

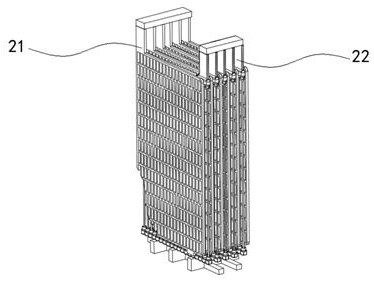

[0024] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

[0025] A method for preparing a lithium battery pole piece, comprising the following steps:

[0026] The first step is to form a semi-finished product with a metal coating on the surface of the metal substrate by physical vapor deposition in a negative pressure inflated environment;

[0027] In the second step, the semi-finished product processed in the first step is cut into the required battery pole piece shape by laser cutting in a negative pressure inflatable environment.

[0028] In the above scheme, the negative pressure inflation environment is an environment with an air content of 99.9999% nitrogen, so that the environment is in a normal and safe negative pressure state, and at the same time, it also avoids the influence of other factors such as oxygen on the production and processing of battery pole pieces.

[0029] And the phy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com