Subsurface defect detection device

A sub-surface defect and detection device technology, applied in the field of defect detection, can solve the problems of high synchronization control stability requirements, strong mechanical vibration interference, low detection efficiency and speed, etc., to avoid mechanical vibration interference and improve imaging efficiency and speed , The effect of reducing the difficulty of synchronous control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It can be seen from the background technology that the detection devices for subsurface defects in the prior art have the problems of strong mechanical vibration interference, high difficulty in synchronous control, and low detection efficiency and speed. The reasons for the above problems are now analyzed in combination with a detection device for subsurface defects:

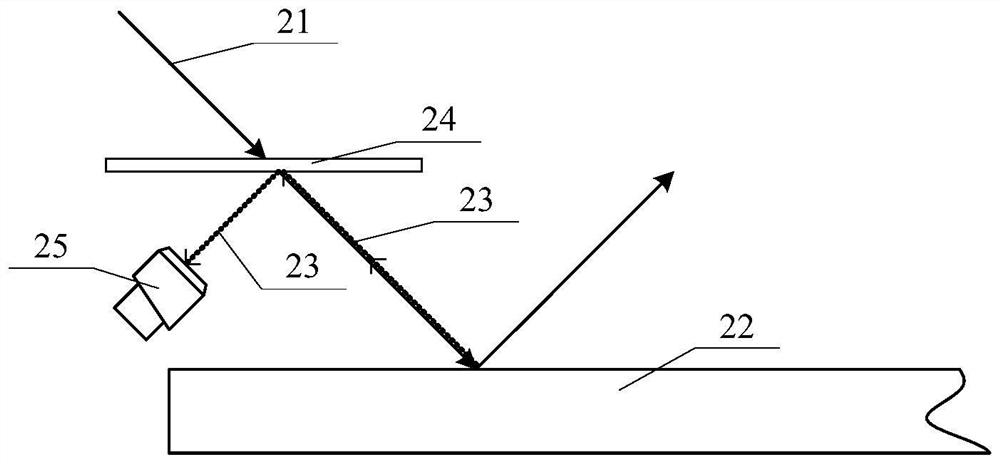

[0035] refer to figure 1 , shows a schematic diagram of the optical path of a detection device for subsurface defects.

[0036] The illumination light 21 produced by the light source (not shown in the figure) is incident on the surface of the object to be imaged 22; ray 23 for imaging.

[0037] In order to improve the local illumination light intensity, the imaging device generally adopts a line light source to generate illumination light 21, so the formed illumination light 21 is a one-dimensional light in the direction perpendicular to the paper surface; , the incident position of the illuminating l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com