Robot comprehensive sampling and preparation system and method in metallurgical industry

A sample preparation system and robot technology, applied in the field of metallurgy, can solve the problems of limited sample preparation and detection functions, limited functions, etc., and achieve the effects of processing a variety of ores, complete sampling and preparation functions, and convenient equipment management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

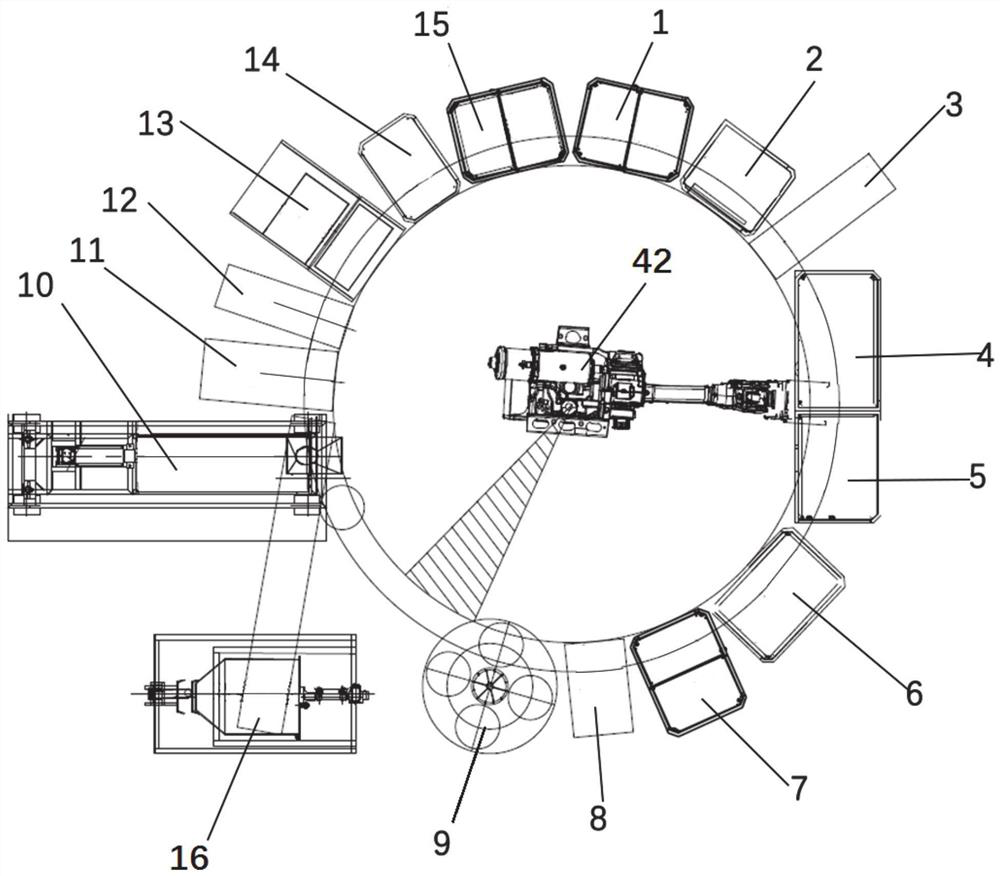

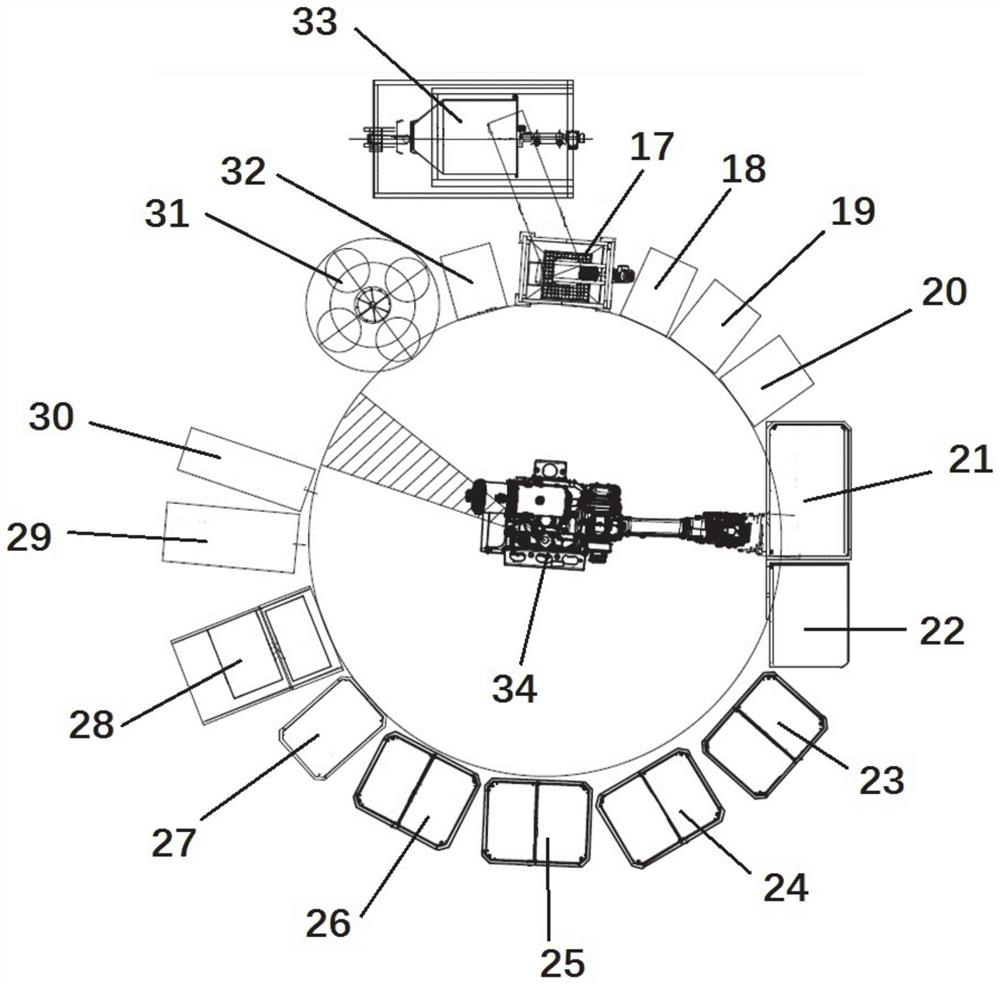

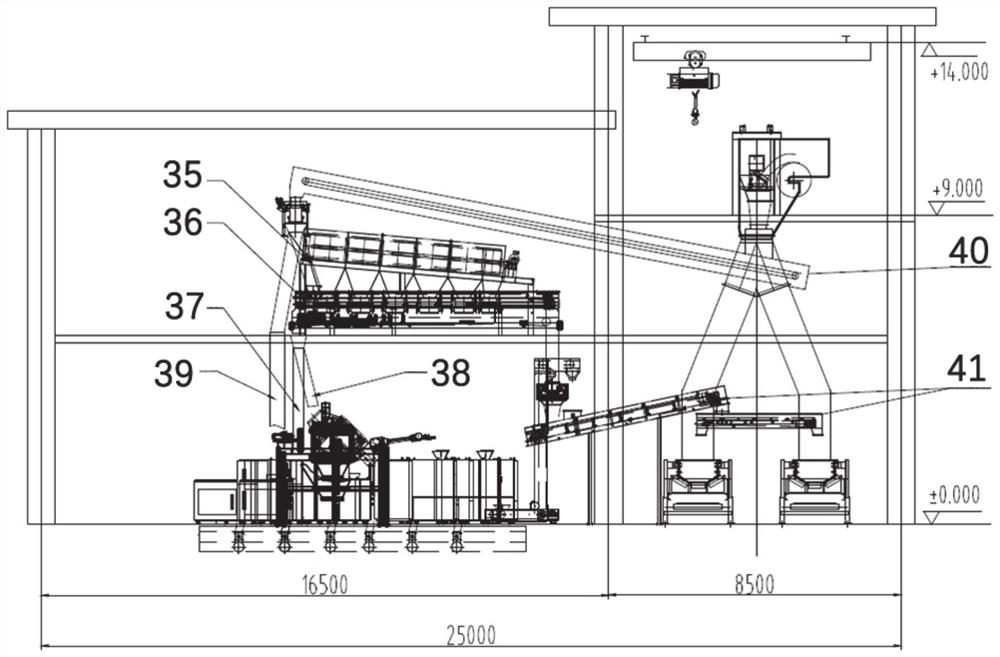

[0049] In a typical implementation of the present invention, this embodiment discloses a robot comprehensive sample preparation system in the metallurgical industry, including a first sample preparation system and a second sample preparation system, the first sample preparation system is used for coke and Coal sampling and preparation, the second sample preparation system is used to prepare samples for pellets, mineral powder, ore and limestone; it also includes two space six-axis robots, named the first robot and the second robot respectively, the first sample preparation The system is set around the first robot, and the second sample preparation system is set around the second robot.

[0050] Please refer to figure 1 , the first sample preparation system includes coal pulverizing equipment 15, coke pulverizing equipment 1, the first double-layer oven 2, 3mm jaw crusher 3, the first shrinking equipment 4, and the first discarding hopper arranged in a clockwise direction Lift...

Embodiment 2

[0062] In a typical implementation of the present invention, this embodiment discloses a coal sample preparation method, using a robot comprehensive sampling and preparation system for the metallurgical industry as described in Embodiment 1, including the following steps:

[0063] The coal enters the first sample preparation system in Example 1 through the head sampling machine. After the sample volume reaches a certain weight, it automatically enters the sample preparation process.

[0064] The coal sample enters the 13mm crusher for crushing, and after being evenly shrunk, it is divided into three parts. The first part detects the moisture and takes out the water sample, enters the oven for moisture measurement, and the data is automatically saved and uploaded; the second part is discarded; the third part The moisture is initially measured by the infrared water meter on the belt conveyor. When the moisture is low, it is directly ground to 3mm. When the moisture exceeds a cert...

Embodiment 3

[0070] In a typical implementation of the present invention, the present embodiment discloses a method for preparing samples of pellets, using a robot comprehensive sampling and preparing system for the metallurgical industry as described in Embodiment 1, comprising the following steps:

[0071] The pellets enter the second sample preparation system in Example 1 through the head sampling machine. After the sample volume reaches the set weight, it automatically enters the sample preparation process. Divide into three for the first time.

[0072] The first ore sample after shrinking is crushed by a 13mm crusher, and after being evenly shrunk, it is divided into three parts. The first part is crushed to 13mm for shrinking; the second part is stored; Content test, moisture data is automatically saved and uploaded.

[0073] After the water is measured, the sample is then divided. The divided sample is divided into three parts, the first part is discarded, and the second part is br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com