Multilayer fabric and manufacturing method thereof

A technology of the fabric, manufacturing industry, applied in the field of industrial fabrics, which solves the problems of expensive, bulky looms, and time-consuming preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that in this disclosure, especially in the claims and / or paragraphs, terms such as "comprising", "comprising", "consisting of" etc., have the meanings indicated in the US Patent Law; that is, may refer to " includes", "comprises", "comprises", "including but not limited to", etc., and components not explicitly listed are permissible. Terms such as "consisting essentially of" and "consisting essentially of" have the meaning given in U.S. patent law, that is, they allow components not expressly recited, but do not include those already in the prior art, or that affect the present invention. An essential feature of an invention or an integral part of its novel character. These and other embodiments are disclosed or expressly included in light of the following description.

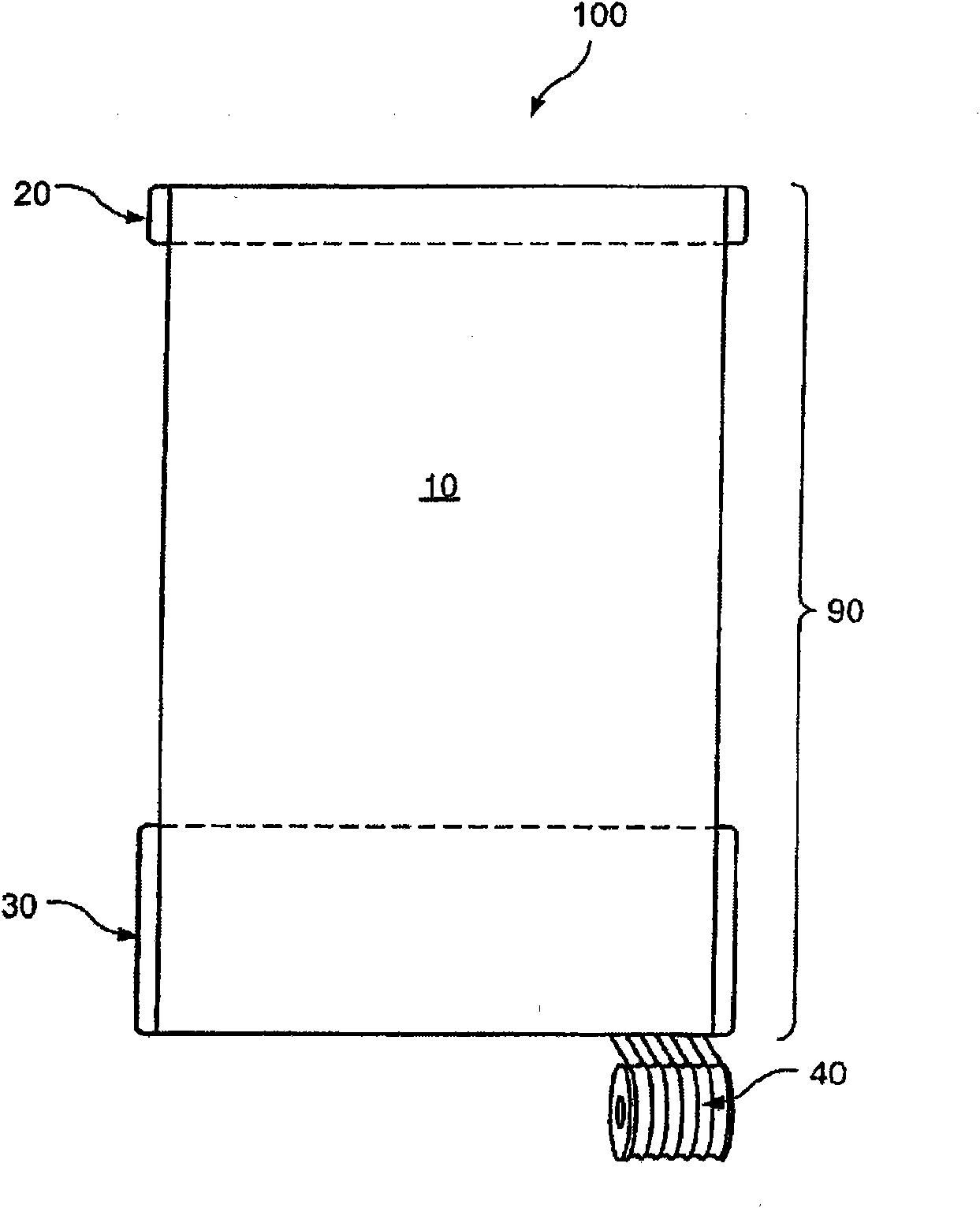

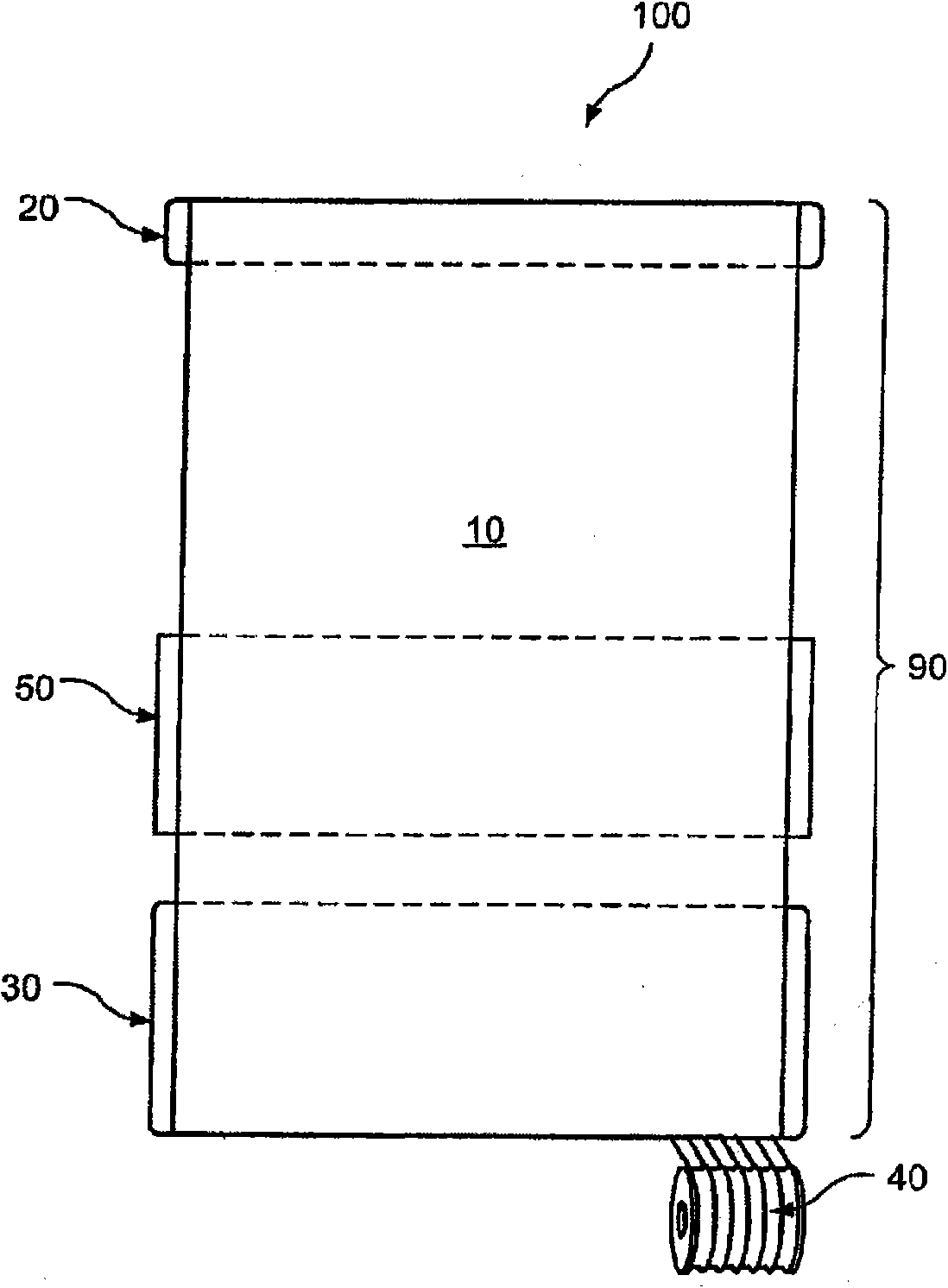

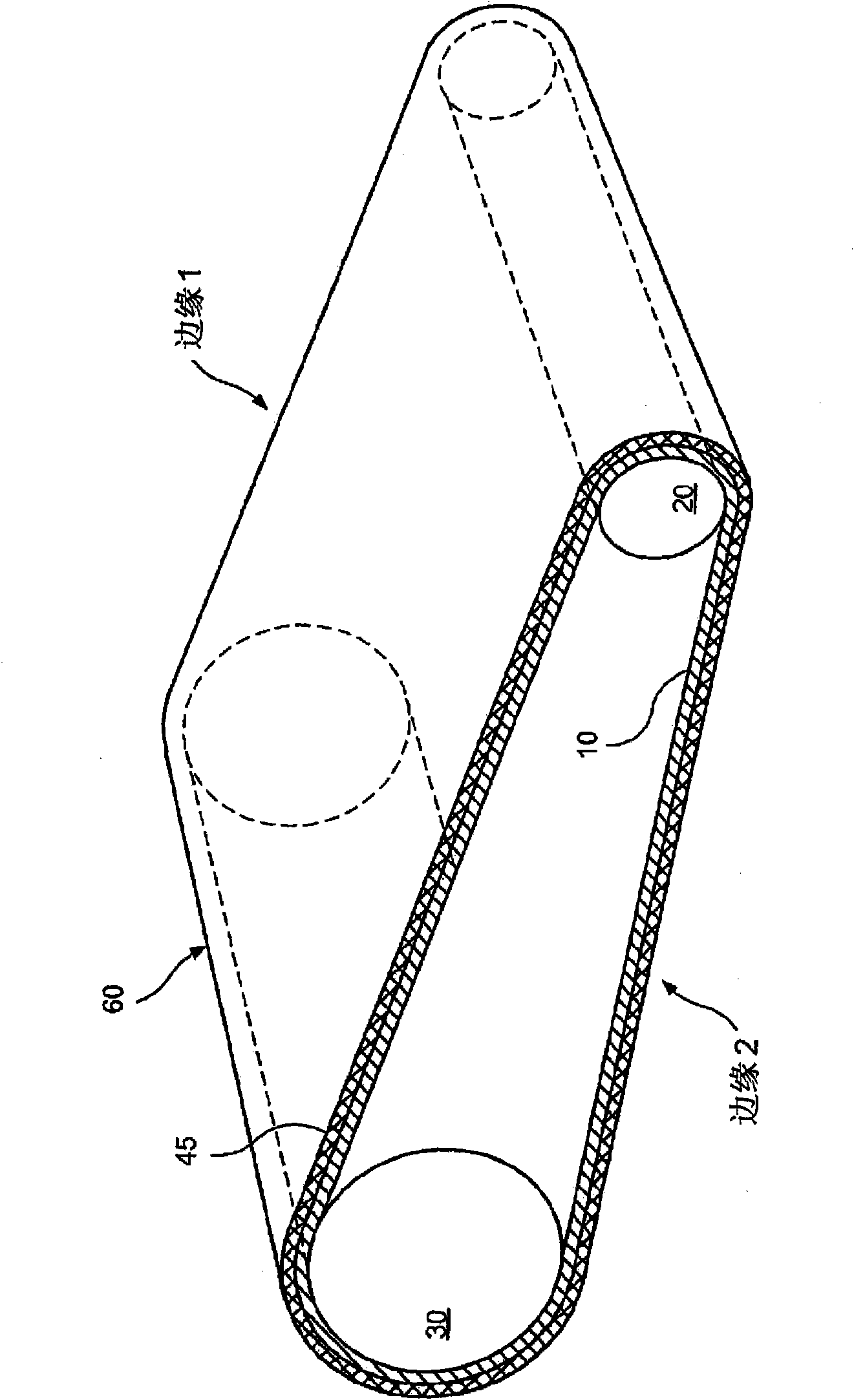

[0036] According to one of its embodiments, the invention is a production method and device for producing multi-layer endless fabrics via the technique of multiple folding, which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com