Heavy oil hydrogenation method

A technology for hydrogenation reaction and hydrogenation products, which is applied in the fields of hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc. consumption, reduce energy loss, reduce the effect of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] Specific embodiments of the present invention will be provided below in conjunction with the accompanying drawings. Unless otherwise specified, the devices and devices used in the examples are conventional devices and devices well known to those skilled in the art.

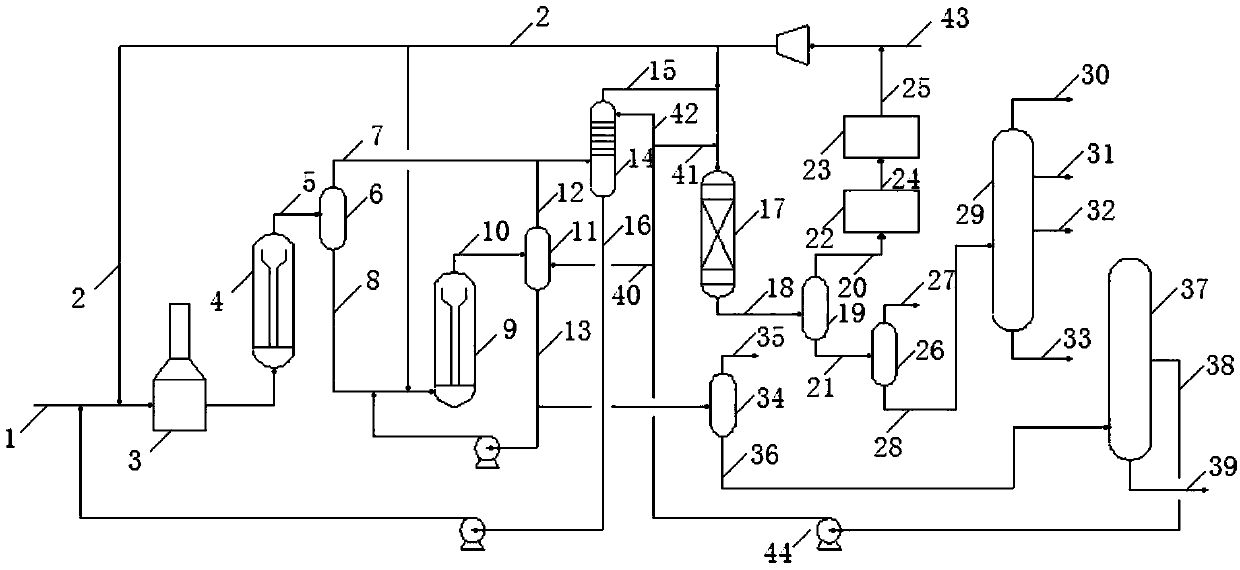

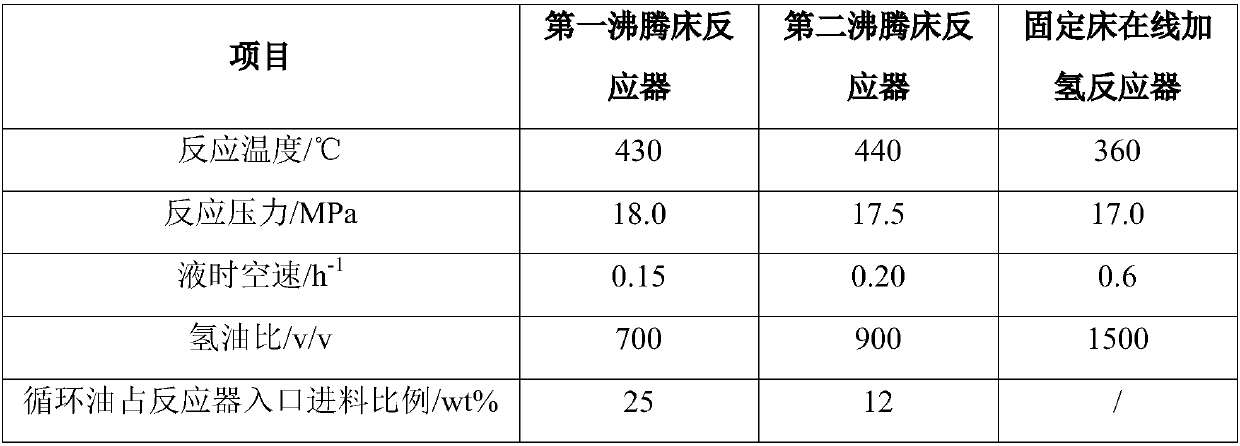

[0078] Such as figure 1 As shown, after the raw material oil 1 is diluted with the tower bottom oil 16, it is mixed with supplementary hydrogen 2 and enters the raw material heating furnace 3 to heat up, and then enters the first ebullating bed reactor 4 respectively, and contacts with the first hydrogenation catalyst to perform the first hydrogenation. Hydrogen reaction to obtain interstage hydrogenation product 5, make interstage hydrogenation product 5 enter interstage gas-liquid separator 6 for gas-liquid separation, obtain interstage separation liquid 8 and interstage separation gas 7, make interstage separation liquid 8 be After being diluted with part of the hot high-fraction liquid returned to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com