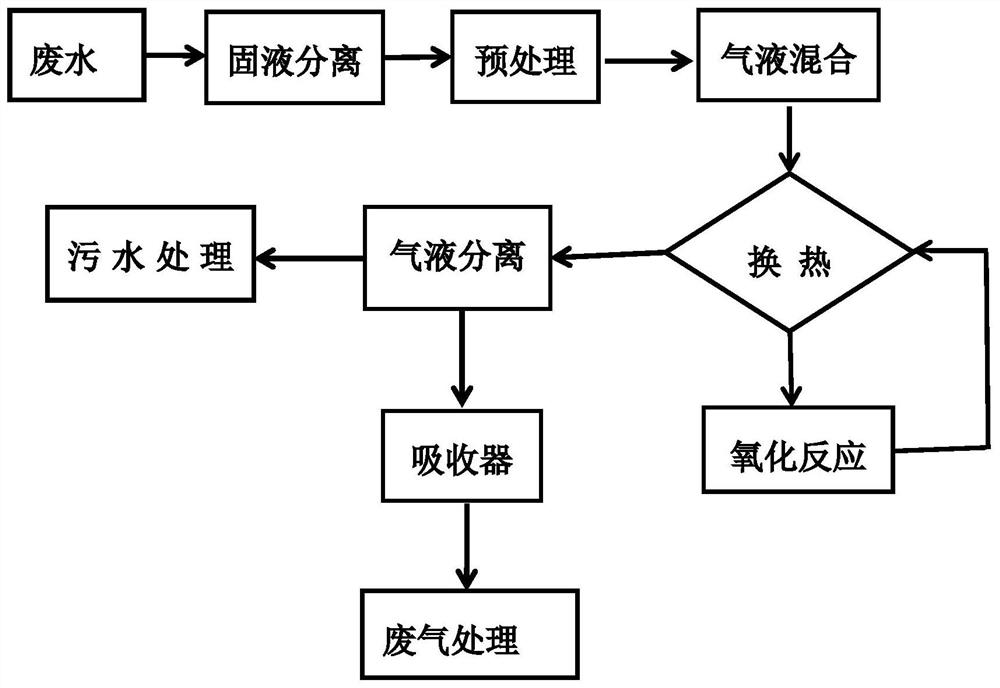

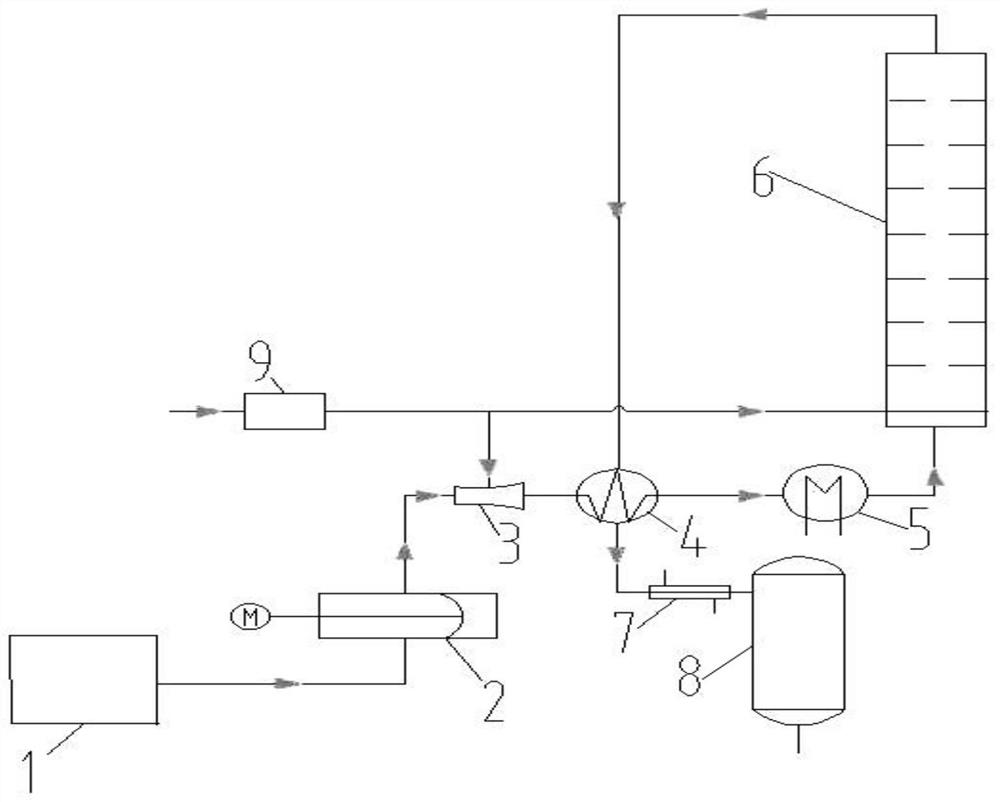

Treatment method of polyether polyol production wastewater and equipment for implementing treatment method

A technology of polyether polyol and treatment method, which is applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of high equipment investment and treatment cost, high requirement of wastewater composition, complicated technological process, etc. Achieve the effect of low processing cost, stable reaction, simple and easy process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Take the high-concentration organic wastewater discharged from the polyether polyol device, filter and separate the suspended solids in it, and obtain the organic liquid wastewater solution. After the GC-MS analyzer, it can be seen that the components in it are: acrylonitrile, styrene, isopropanol The COD value of the liquid waste water is 25600 mg / L and the BOD5 / COD value is 0.12 by using the COD rapid tester to analyze the COD value of 0.12; among them, the detection method of BOD5 is: in the microbiology laboratory, the water sample is diluted 10 times and then filled with After the culture bottle is plugged, it should be airtight, and the bottle is placed in an incubator at a constant temperature of 20°C for 5 days. The dissolved oxygen concentration was measured before and after cultivation, and the difference between the two can be used to calculate the mass of oxygen consumed per liter of water, that is, the BOD5 value.

[0082] Put the liquid waste water into th...

Embodiment 2

[0085] Take the high-concentration organic wastewater discharged from the polyether polyol device, and centrifuge to separate the suspended solids in it. The organic liquid wastewater solution obtained through the GC analyzer shows that the components in it include: acrylonitrile, styrene, isopropanol, etc. Composition, the COD value of liquid waste water is 30,000mg / L and the BOD5 / COD value is 0.09 after analysis with a COD rapid analyzer; among them, the detection method of BOD5 is: in the microbiology laboratory, dilute the water sample by 10 times and then fill it with culture After the bottle is plugged, it should be airtight, and the bottle is placed in an incubator at a constant temperature of 20°C for 5 days. The dissolved oxygen concentration was measured before and after cultivation, and the difference between the two can be used to calculate the mass of oxygen consumed per liter of water, that is, the BOD5 value.

[0086] Put the liquid waste water into the liquid s...

Embodiment 3

[0089] Take out a part of the mixed high-concentration wastewater discharged from the polyether polyol production unit, and obtain a liquid wastewater solution after filtration and separation. After analysis, it can be seen that the components include acrylonitrile, styrene, azobisisobutyronitrile and other components. Quickly use COD The COD value of the waste water was analyzed by the analyzer to be 28000mg / L, and the BOD5 / COD value was 0.1. Among them, the detection method of BOD5 is: in the microbiological laboratory, dilute the water sample by 10 times and then fill the culture bottle. Ventilate, and place the bottle in an incubator at a constant temperature of 20° C. for 5 days. The dissolved oxygen concentration was measured before and after cultivation, and the difference between the two can be used to calculate the mass of oxygen consumed per liter of water, that is, the BOD5 value.

[0090] Put the liquid waste water into the liquid storage tank and add a certain amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com