A niobium-based oxide material, its preparation method and application

A negative electrode material and reactor technology, which is applied in the field of niobium-based oxide materials, can solve the problems of increased lithium intercalation overpotential of graphite negative electrode, unsuitable high-rate charge and discharge, and risk of lithium precipitation in the electrode, so as to increase the active surface area, Good safety and stability, the effect of avoiding the risk of lithium analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

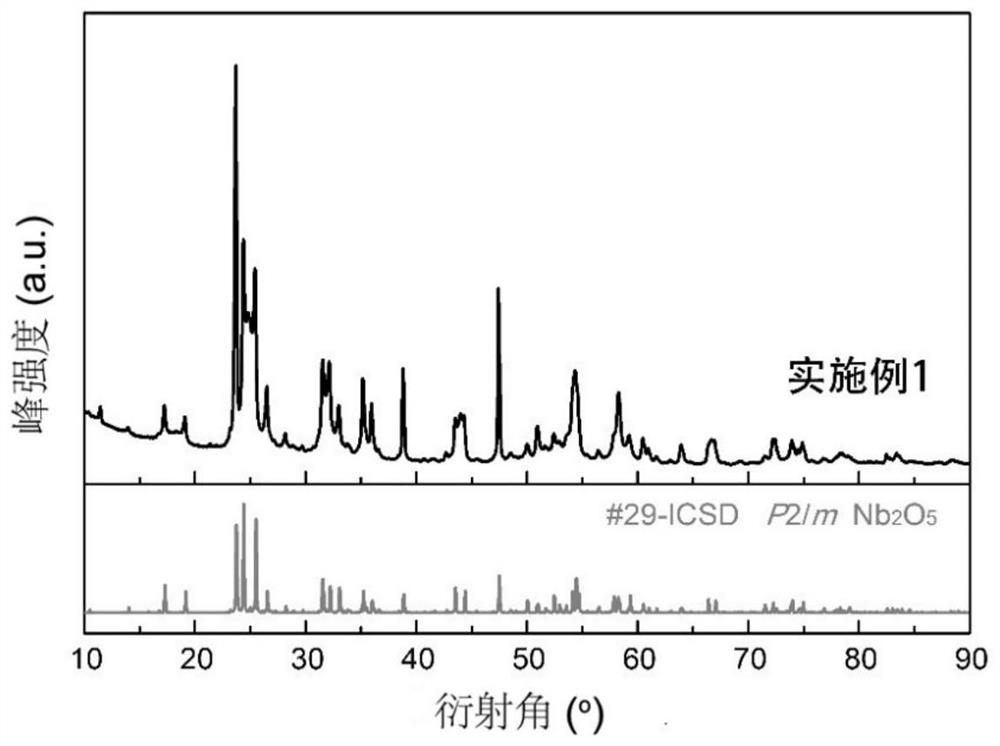

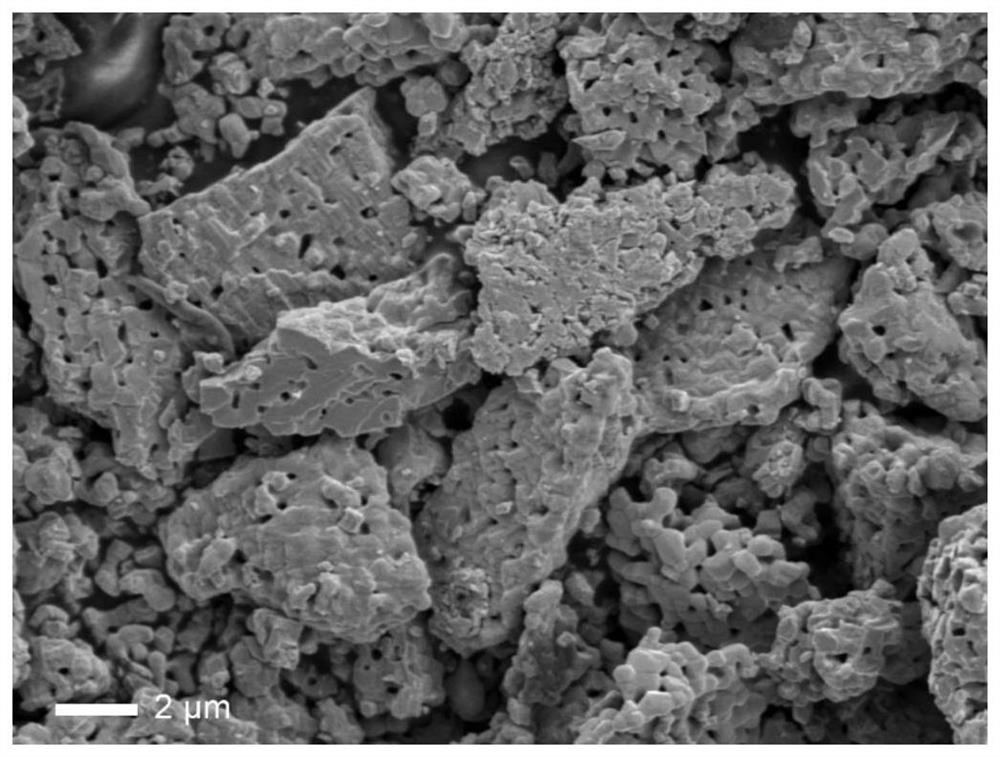

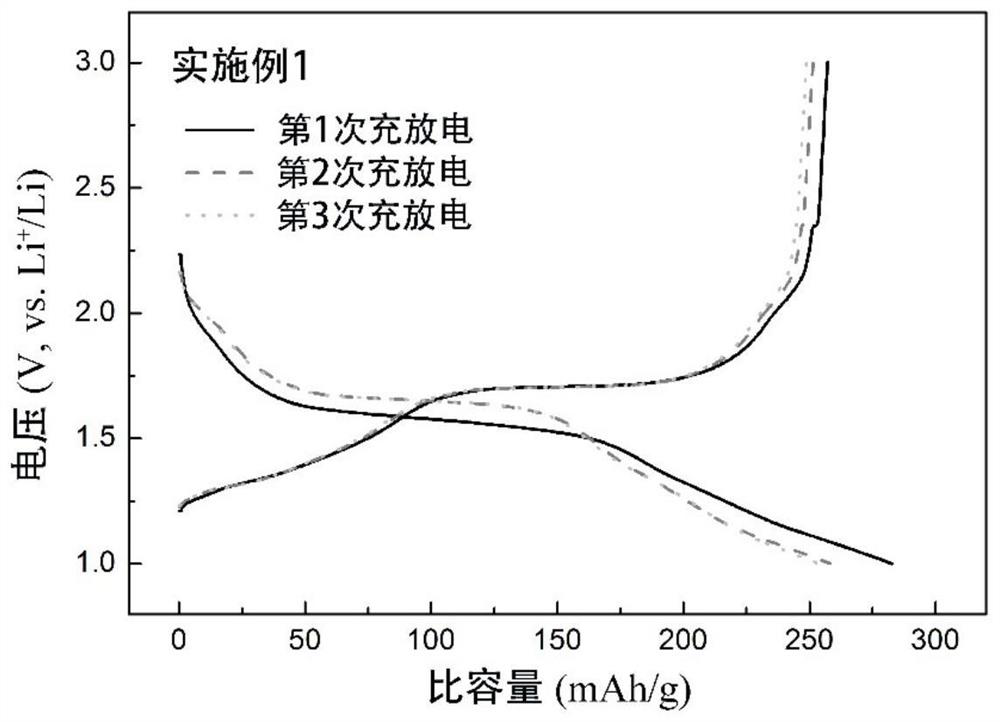

[0047] Nb 2 O 5 Preparation of material (A1):

[0048] Dissolve 0.005mol of niobium oxalate in 90mL of deionized water and 10mL of ethanol, add 0.002g of Pluronic F127 and 0.002g of polyvinylpyrrolidone (molecular weight 40000) and stir until dissolved to obtain a uniform solution; transfer the above solution to the reaction kettle and put it into a microwave In the reactor, the power of the microwave reactor is 1000W. First, the temperature in the reactor rises from room temperature to 100 °C for 10 minutes, and the temperature is kept constant for 5 minutes; then the temperature is continued to rise for 40 minutes to 180 °C, and the constant temperature reaction is performed for 2 hours; after cooling to room temperature, centrifuge to obtain a solid The product was washed twice with deionized water and once with ethanol, and then dried in a vacuum oven at 90 °C for 12 h to obtain a precursor; the obtained precursor was transferred to a corundum crucible, and placed in a mu...

Embodiment 2

[0052] Nb 2 O 5 Preparation of material (A2):

[0053] Nb in Example 2 2 O 5 The difference in the preparation method of material (A2) is that the surfactants are 0.002g Pluronic F127 and 0.002g sodium dodecyl sulfate, and other reaction steps and conditions are the same as those in Example 1.

[0054] Preparation of half-cell (B2):

[0055] with Nb 2 O 5 The steps and conditions for preparing the half-cell (B2) with the material (A2) as the electrode active material are the same as those in Example 1.

Embodiment 3

[0057] Nb 2 O 5 Preparation of material (A3):

[0058] Nb in Example 3 2 O 5 The difference in the preparation method of material (A3) is that the solvent used is 90 mL of deionized water and 10 mL of ethylene glycol, and other reaction steps and conditions are the same as those in Example 1.

[0059] Preparation of half-cell (B3):

[0060] with Nb 2 O 5 The steps and conditions for preparing the half-cell (B3) with the material (A3) as the electrode active material are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com