Organic near-infrared light detection diode with low dark current

A technology for detecting diodes and near-infrared light, which is applied in organic semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of large dark current and achieve the effects of reducing injection current, reducing current generation, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The transparent conductive glass having a strip-like ITO (anode) is sequentially cleaned with a cleaning agent, deionized water, acetone and isopropanol ultrasonic oscillators, dry, then treated with ultraviolet ozone for 15 minutes; then will contain crosslinking The agent mass fraction is 10%, the total concentration is 6.6 mg ml -1 The polytpd solution was spin coated on the conductive glass substrate, the rotational speed was 1000 rpm, the spin coating time was 60 seconds, and then the ultraviolet light was taken for 10 minutes, and finally at 150 ° C for 20 minutes in the air. The resulting polytpd film thickness was 24 nm. The film was then transferred into the glove box and deposited by a spin coating method by a spin coating method, and the thickness was 180 nm. Thereafter, use the vapor deposition apparatus to coastal plating 60 And LIF is plated onto the light absorbing layer by volume ratio 1: 2, the thickness is 40 nm. Finally, a 100 nm thick Al electrode (catho...

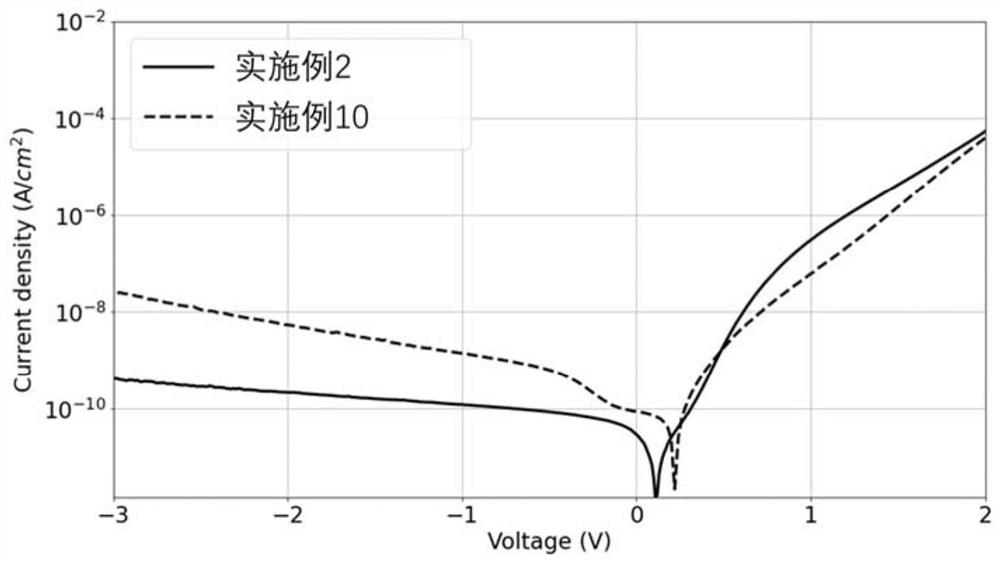

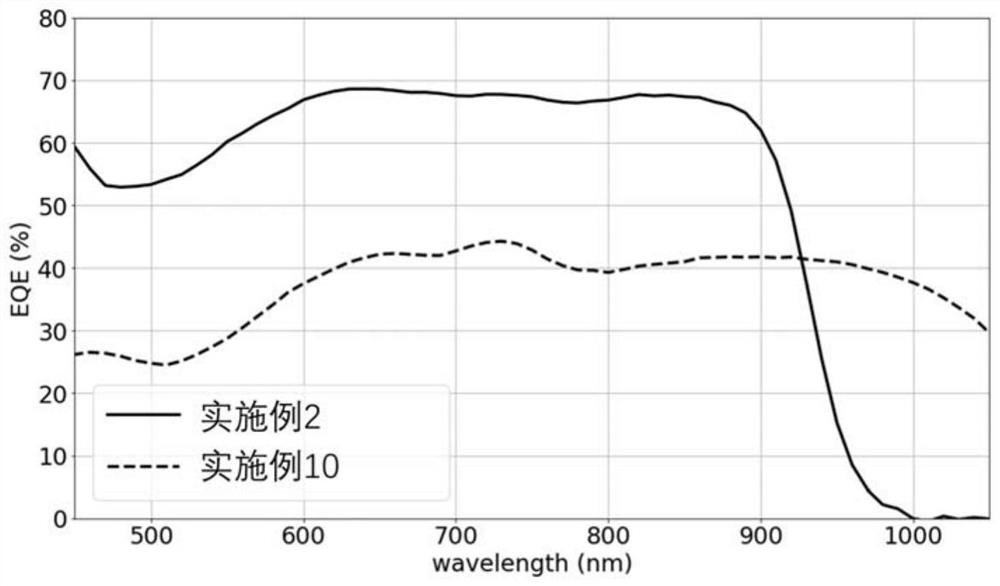

Embodiment 2

[0019] The transparent conductive glass having a strip-like ITO (anode) is sequentially cleaned with a cleaning agent, deionized water, acetone and isopropanol ultrasonic oscillators, dry, then treated with ultraviolet ozone for 15 minutes; then will contain crosslinking The agent mass fraction is 10%, the total concentration is 6.6 mg ml -1 The polytpd solution was spin coated on the conductive glass substrate, the rotational speed was 1000 rpm, the spin coating time was 60 seconds, and then the ultraviolet light was taken for 10 minutes, and finally at 150 ° C for 20 minutes in the air. The resulting polytpd film thickness was 24 nm. The film was then transferred into the glove box and deposited by a spin coating method by a spin coating method, and the thickness was 180 nm. Thereafter, use the vapor deposition apparatus to coastal plating 60 And LIF is deposited on the light absorbing layer by volume ratio of 1: 4, the thickness is 40 nm. Finally, a 100 nm thick Al electrode (c...

Embodiment 3

[0022] The transparent conductive glass having a strip-like ITO (anode) is sequentially cleaned with a cleaning agent, deionized water, acetone and isopropanol ultrasonic oscillators, dry, then treated with ultraviolet ozone for 15 minutes; then will contain crosslinking The agent mass fraction is 10%, the total concentration is 6.6 mg ml -1 The polytpd solution was spin coated on the conductive glass substrate, the rotational speed was 1000 rpm, the spin coating time was 60 seconds, and then the ultraviolet light was taken for 10 minutes, and finally at 150 ° C for 20 minutes in the air. The resulting polytpd film thickness was 24 nm. The film was then transferred into the glove box and deposited by a spin coating method by a spin coating method, and the thickness was 180 nm. Thereafter, use the vapor deposition apparatus to coastal plating 60 The LIF is concentrated on the light absorbing layer by volume ratio 1: 6, the thickness is 40 nm. Finally, a 100 nm thick Al electrode (c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com